Thermal expansion technology for high-energy rubber-molded fiber composite product

A high-energy glue and thermal expansion technology, which is applied in the field of thermal expansion technology of high-energy glue forming fiber composite products, can solve problems such as production troubles, easy air leakage of nylon tubes, increase in defective product rate, etc., to solve appearance problems, shorten processing flow, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

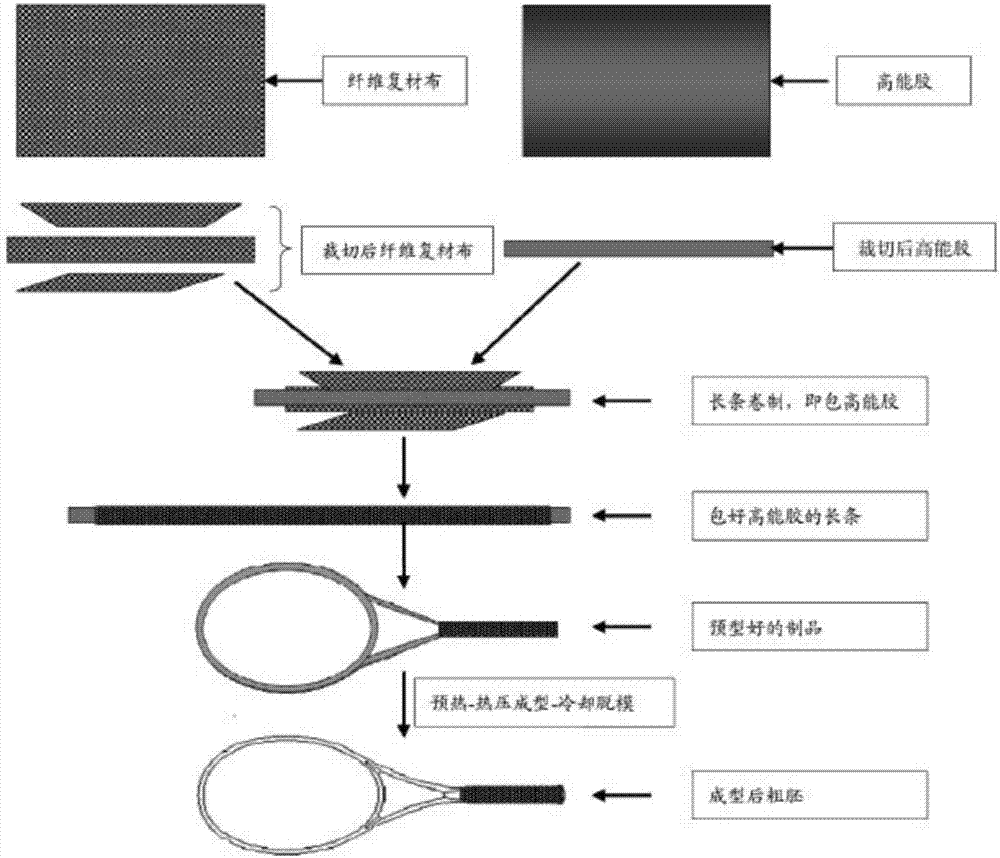

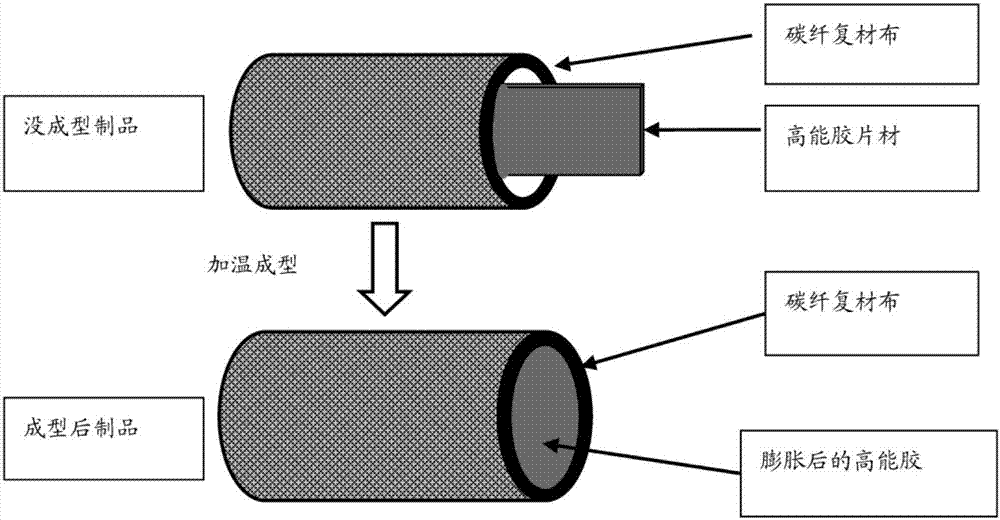

[0034] refer to Figure 1-Figure 2 ,in figure 1 Take the racket handle as an example to illustrate the thermal expansion process flow chart of the high-energy glue molded fiber composite product of the present invention, figure 2 It is an enlarged schematic diagram of the structural flow of the present embodiment.

[0035] For the production of tennis rackets, the high-energy glue with a thickness of 0.7mm (the HR-312-W of Xiamen Hower New Materials) with a thickness of 0.7mm (starting expansion temperature 120°C, maximum expansion temperature 155°C) is cut into about 20mm wide according to the structure, and then according to the structure Cut the fiber composite cloth to the required width, then wrap the high-energy adhesive sheet on the outside of the fiber composite cloth, preheat it on a heating table at 60°C for 10 minutes according to the preform of the tennis racket frame, squeeze as much as possible to remove the interlayer Gas, press it smoothly, then put the prod...

Embodiment 2

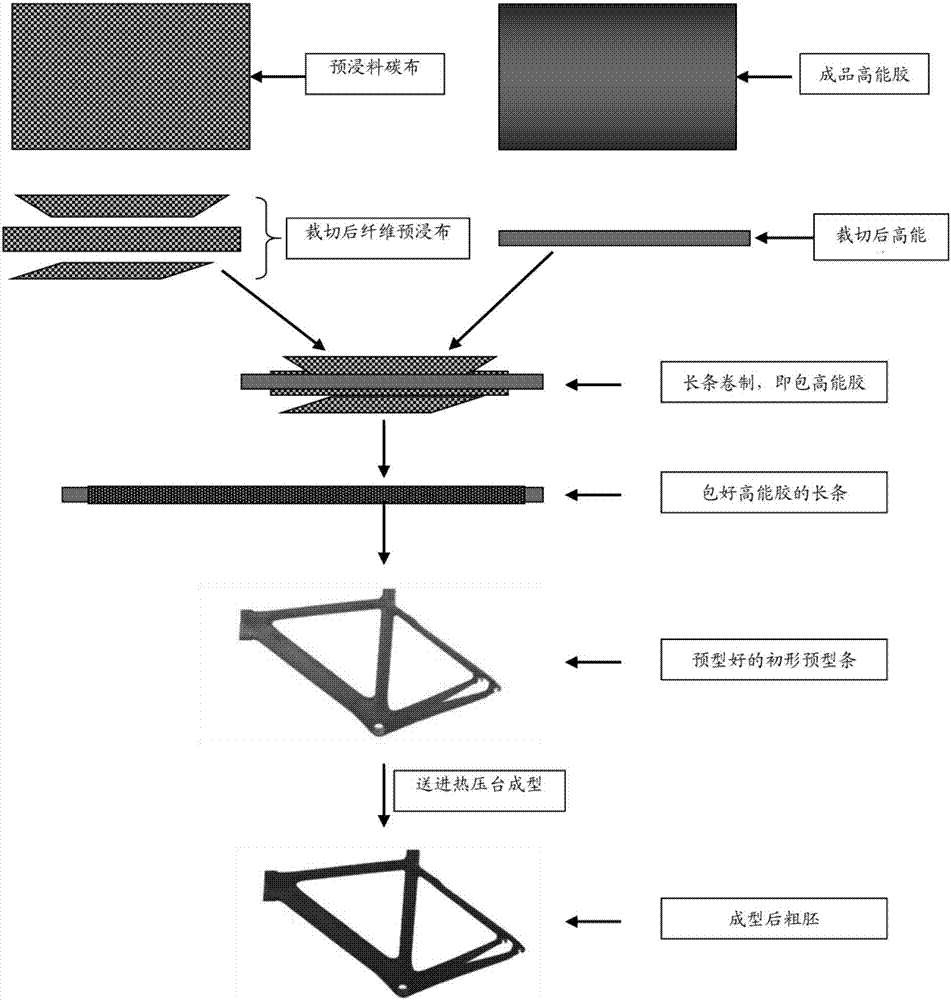

[0038]refer to image 3 and Figure 4 ,in image 3 Taking a bicycle as an example to illustrate the thermal expansion process flow chart of the high-energy glue molded fiber composite product of the present invention. Figure 4 It is an enlarged schematic diagram of the structural flow of the present embodiment.

[0039] For the production of carbon fiber bicycles, the high-energy adhesive with a thickness of 0.7mm (the starting expansion temperature is 120°C, the maximum expansion temperature is 155°C, sourced from Xiamen Haoer New Materials) is cut into about 35mm wide according to the structure, and then the composite cloth is cut according to the structure Cut it to the desired width, then wrap the high-energy adhesive sheet on the outside of the composite cloth, preheat it on a 50°C heating table according to the frame shape for 60 minutes, squeeze as much as possible to remove the interlayer gas, press it smoothly, and then place the product on the In the preform mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com