Metal cavity broadband antenna

A technology of metal cavity and broadband antenna, which is applied in the direction of antenna, antenna array, radiating element structure, etc., can solve the problems of high profile of printed vibrator antenna array, low heat conduction of antenna array, narrow impedance bandwidth, etc., to achieve the benefit of static electricity The effect of discharge protection design, reduction of processing process, and reduction of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Metal cavity broadband antenna working in X-band wavelength 25.6~41.1mm, center frequency wavelength λ 0 It is 31.58mm, the center frequency is 9.5GHz, the lower frequency is 7.3GHz, and the upper frequency is 11.7GHz.

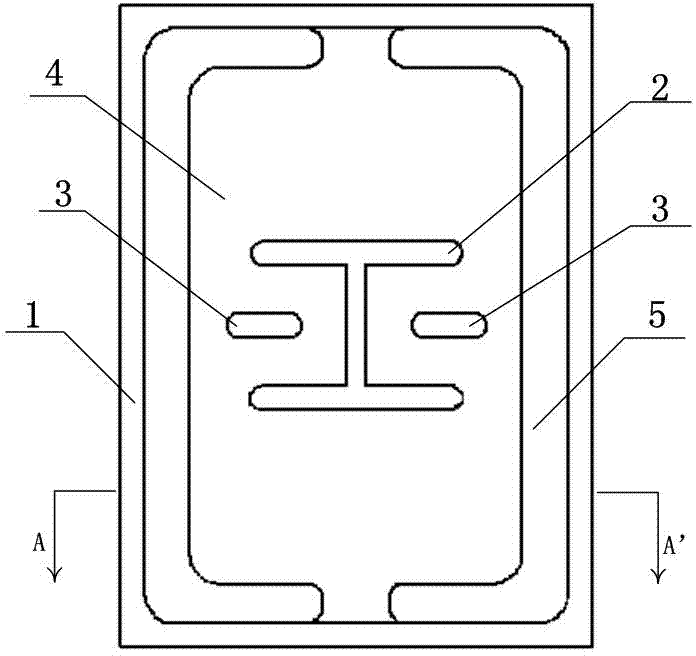

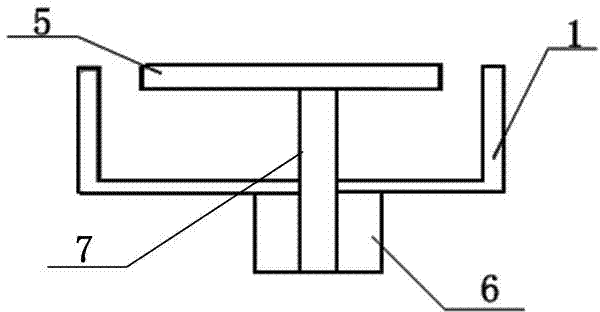

[0032] see figure 1 , figure 2 and image 3 , the metal cavity broadband antenna is a flat box-shaped hollow metal cavity 1, the top middle of the metal cavity 1 is provided with an I-shaped seam 2, the two ends of the I-shaped seam 2 are horizontal seams, and the middle is a vertical seam; Both sides of the middle part of the seam 2 are symmetrically provided with a line seam 3, and the I-shaped seam 2 and the line seam 3 on both sides are radial seams. A coaxial connector 6 is installed on the bottom of the metal cavity 1 , and the inner conductor 7 of the coaxial connector 6 extends into the metal cavity 1 and is connected to the inner top of the metal cavity 1 .

[0033] see Figure 4 and Figure 5 , the inner dimension of metal cavity 1: len...

Embodiment 2

[0039] see Figure 12 , this embodiment is extended from Embodiment 1, and is mainly aimed at the two-dimensional scanning planar phased array antenna required in practical applications.

[0040] The planar array antenna consists of 4×4 metal cavity broadband antennas in Embodiment 1, 16 metal cavity broadband antenna units are arranged in two-dimensional expansion, and the adjacent side walls of adjacent metal cavity broadband antennas are common walls (Adjacent cavities share metal walls); the 4×4 planar array antenna can be processed as a unit module of a planar phased array antenna. The working frequency of the antenna array is 7.3~11.7GHz, working in the X-band with a wavelength of 25.6~41.1mm, and the center frequency wavelength is λ 0 It is 31.58mm.

[0041] According to actual engineering needs or actual processing capabilities, this example can also be extended to a unit module of a planar phased array antenna composed of 8×8 or 16×16 antennas in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com