Spray-rolling type loose fiber dyeing machine

A technology for bulk fiber and dyeing machines, which is applied in liquid/gas/steam removal with squeeze rollers, spray/jet textile material treatment, textile material carrier treatment, etc., which can solve the problems of long dyeing cycle, high energy consumption, and dyeing Poor uniformity and other problems, to achieve the effect of accelerated diffusion and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

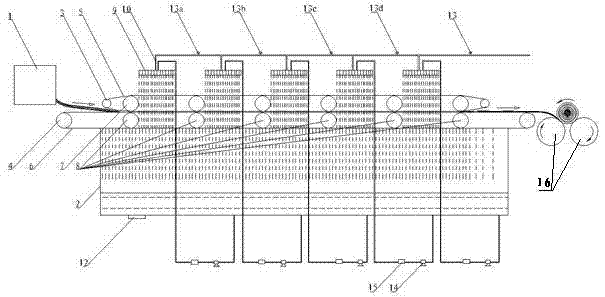

[0023] The present embodiment pours and rolls the loose fiber dyeing machine, combines figure 1 , including a transmission part and a spraying part, the transmission part includes a pair of upper driving rollers 3 and a pair of lower driving rollers 4, the upper driving rollers 3 and the lower driving rollers 4 are respectively sleeved with an upper guide belt 5 and a lower guide belt for use together 6. There is a leakage hole 1 on the upper guide belt 5, and the upper guide belt 5 and the lower guide belt 6 run synchronously. Several upper rolls 7 are installed in the upper guide belt 5 circuit, and several rollers 7 are installed in the lower guide belt 6 circuit. The lower roller 8 used in conjunction with the upper roller, the upper guide belt 5, the lower guide belt 6, the upper roller 7, and the lower roller 8 cooperate to realize the synchronous clamping and conveying of loose fibers; the spraying parts include the spraying head 9 and the dyeing liquid pipe 10. One end...

Embodiment 2

[0028] In this embodiment, a circulation component is arranged below the lower guide belt 6, and the circulation component includes a liquid sump 2, a return pipe 11, a liquid replenishment pump 14 and a heat exchanger 15, and the return pipe 11 can be provided with a return pipe-11a, a return flow Pipe two 11b, return pipe three 11c, return pipe four 11d and return pipe five 11e, return pipe one 11a, return pipe two 11b, return pipe three 11c, return pipe four 11d and return pipe five 11e are connected to the sump 2 at one end , the other end is sequentially connected with the first sprinkler 9a, the second sprinkler 9b, the third sprinkler 9c, the fourth sprinkler 9d and the fifth sprinkler 9e, and the rehydration pump 14 and the heat exchanger 15 are installed on the return pipe 11 , the replenishment pump 14 pumps the liquid in the liquid collection tank 2 back into the return pipe 11, and the heat exchanger 15 adjusts the temperature of the liquid recycled in the return pi...

Embodiment 3

[0030] Example 3: Conventional Loose Fiber Dyeing

[0031] Dyeing vats are used to dye loose fibers. The dyeing process and process conditions are as follows:

[0032] (1) Pre-treatment: pre-treat the loose fibers under high-temperature alkaline conditions, so that the cotton has better water absorption, which is conducive to the adsorption and diffusion of dyes during dyeing.

[0033] (2) Bleaching and brightening: The pretreated loose fibers are subjected to oxygen bleaching treatment, in which alkali agents and hydrogen peroxide stabilizers need to be added to the oxygen bleaching, and pickling is carried out.

[0034] (3) Dyeing: add dyes and auxiliaries to the bathtub, among which, auxiliaries, salt, sodium sulfate, etc. are needed in the dye, the bath ratio is 1: (10-20), the loose fiber after bleaching and whitening Placed in the dyeing vat, the dyeing solution is transported by the main pump, from the inner layer of the dyeing vat to the outer layer to penetrate and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com