Nitrocarburizing process of Cr12MoV steel

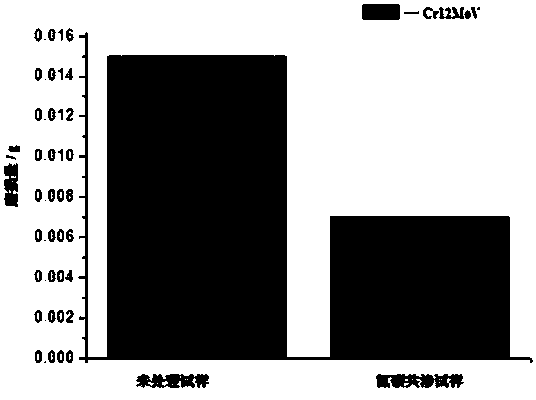

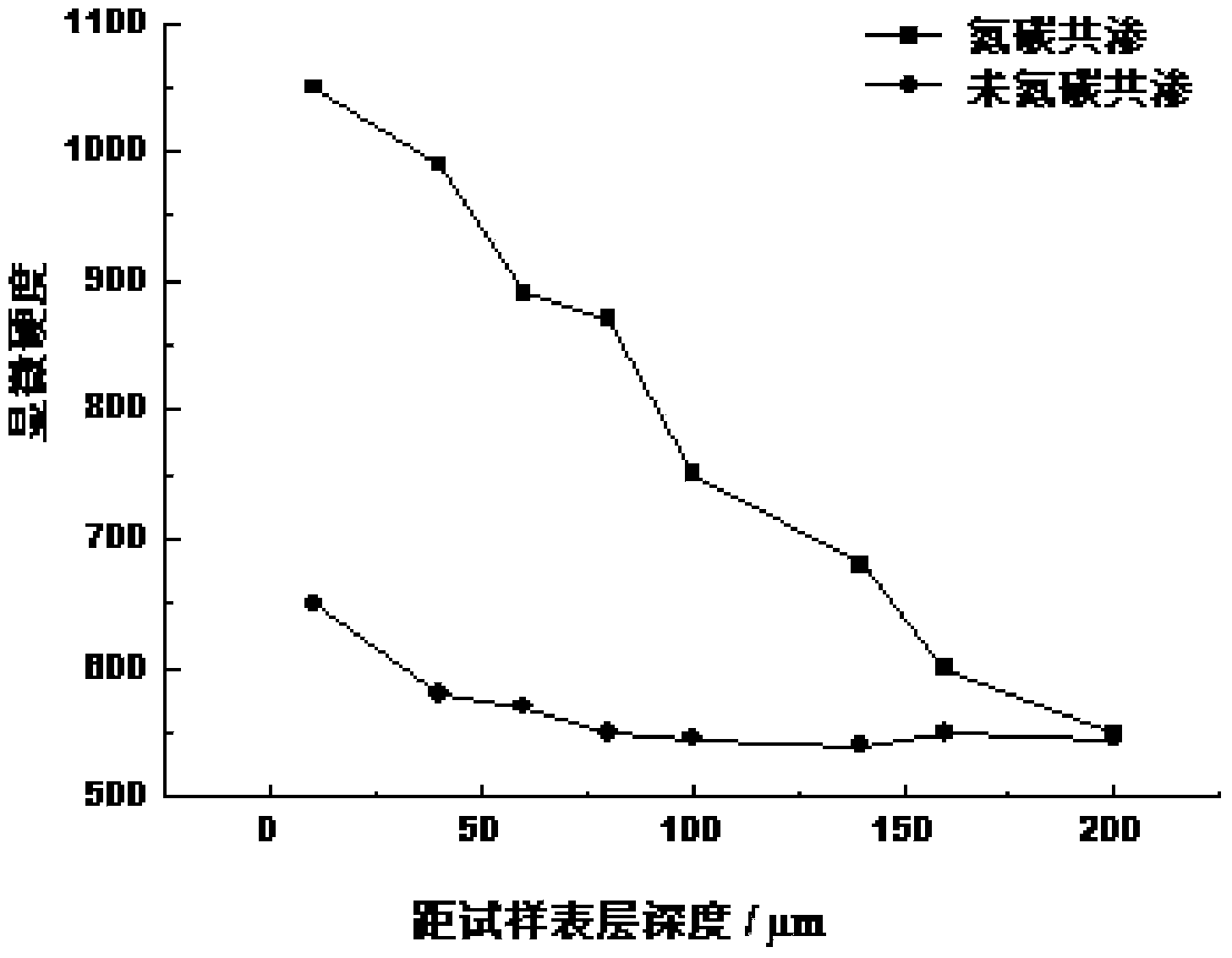

A nitrocarburizing and process technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of short life, reduced mold dimensional accuracy, complex process, etc., and achieve surface hardness improvement and use The effect of prolonging the life and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

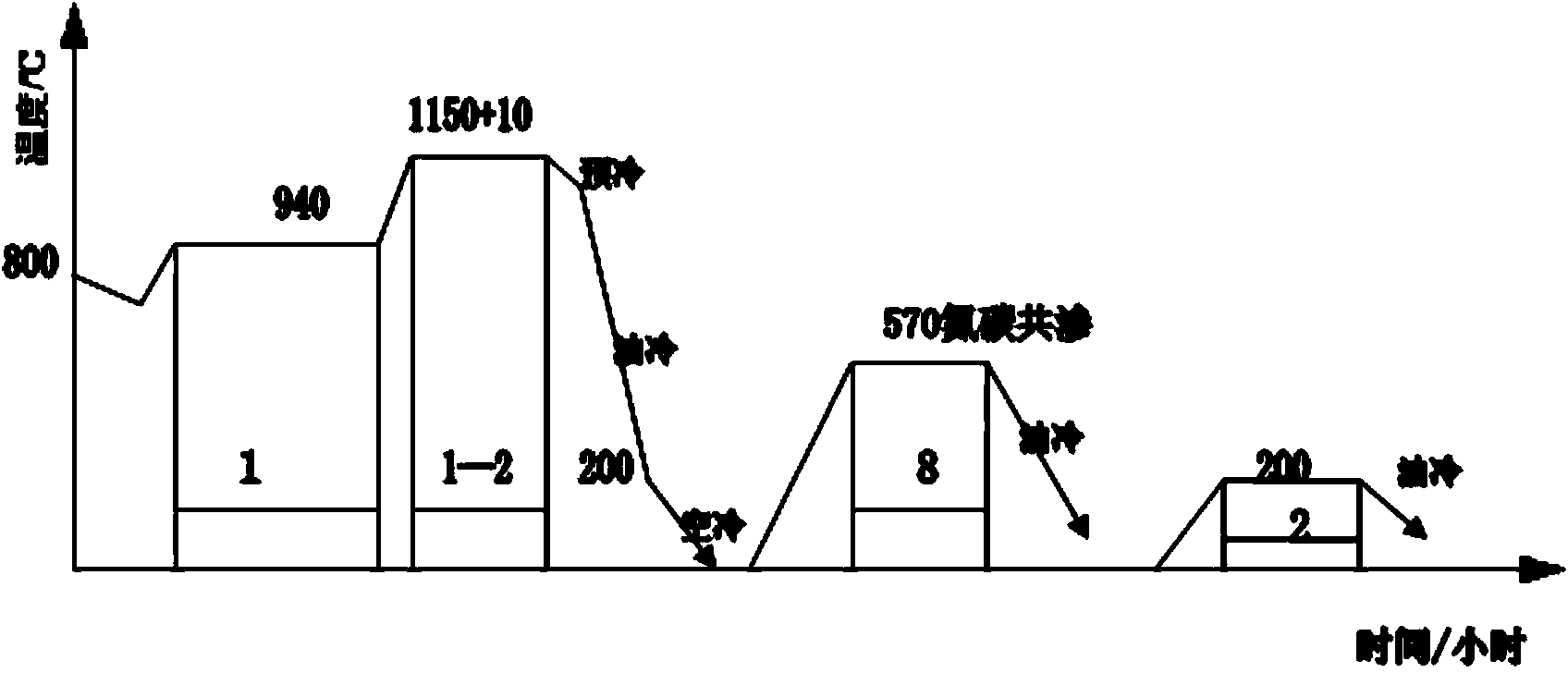

Embodiment 1

[0025] Three Cr12MoV steel molds were subjected to high-temperature quenching with secondary heating at 850°C±5°C for 0.5h; oil quenching at 1150°C±5°C for 0.1h. Take 1800g solid carburizing agent, 1200g urea and 40g chromium trioxide and mix evenly. Then spread a layer of penetrating agent on the bottom of the box, remove oil stains and rust on the surface of the mold, and put them into the box in turn. The thickness of the penetration agent between the mold and the box wall and between the mold and the mold is not less than 10 mm, and the uppermost layer is covered with a thickness of more than 20 mm, and then the penetration agent in the whole box is vibrated and then covered. The gaps between are sealed with wet refractory clay. Then put the seepage box into the electric furnace that has been heated to 570°C and keep it warm for 8 hours. After the holding time, pull the seepage box out of the furnace, open the cover, take out the mold one by one and carry out oil cooling ...

Embodiment 2

[0029] Three stepped Cr12MoV steel molds were subjected to high-temperature quenching with secondary heating at 850°C±5°C for 0.5h; oil quenching at 1150°C±5°C for 0.2h. Take 3000g solid carburizing agent, 2000g urea and 120g chromium trioxide and mix evenly. Then spread a layer of penetrating agent on the bottom of the box, remove oil stains and rust on the surface of the mold, and put them into the box in turn. The thickness of the penetration agent between the mold and the box wall and between the mold and the mold is not less than 10 mm, and the uppermost layer is covered with a thickness of more than 20 mm, and then the penetration agent in the whole box is vibrated and then covered. The gaps between are sealed with wet refractory clay. Then put the infiltration box into an electric furnace heated to 580°C and keep it warm for 7 hours. After the holding time, pull the infiltration box out of the furnace, open the cover, take out the mold one by one and carry out oil cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com