Preparation method of copper-based friction material of brake pad

A technology for friction materials and brake pads, which is applied in the field of preparation of copper-based brake pad friction materials, can solve the problems of poor friction coefficient stability, poor wear resistance, lead pollution, etc., achieve high bonding strength, improve comprehensive performance, and prevent dust pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

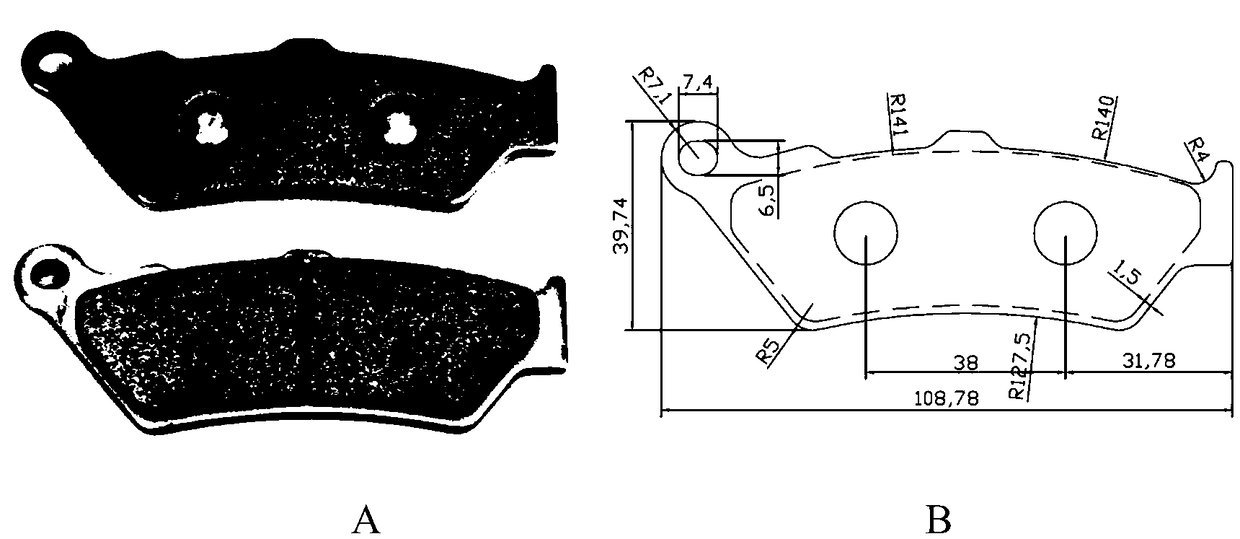

[0036] preparation figure 1 A motorcycle brake pad of a certain type shown includes the following steps:

[0037]Step 1, batching according to the proportion, 38 parts of the main component 250 mesh dendritic electrolytic copper powder, 2.2 parts of 40 micron tin powder, 22 parts of 300 mesh copper-tin composite powder, 1.5 parts of the auxiliary component 300 mesh reduced iron powder, 1 part of 300-mesh zinc powder, 15 parts of 300-micron scaly graphite powder for lubricating components, 2 parts of 200-mesh molybdenum disulfide powder, 1.5 parts of 80-mesh pore-forming agent calcium carbonate, 1.5 parts of friction component 100-mesh kaolin without corners , 2.5 parts of 100 mesh non-angular feldspar powder, 2.5 parts of 100 mesh non-angular zircon powder, 1.3 parts of 100 mesh non-angular high-purity mullite, 1.5 parts of 200 mesh vermiculite, 1.5 parts of 100 mesh aluminum silicate hollow ball share. ready to go.

[0038] Step 2, mixing and granulating, weighing the raw ...

Embodiment 2

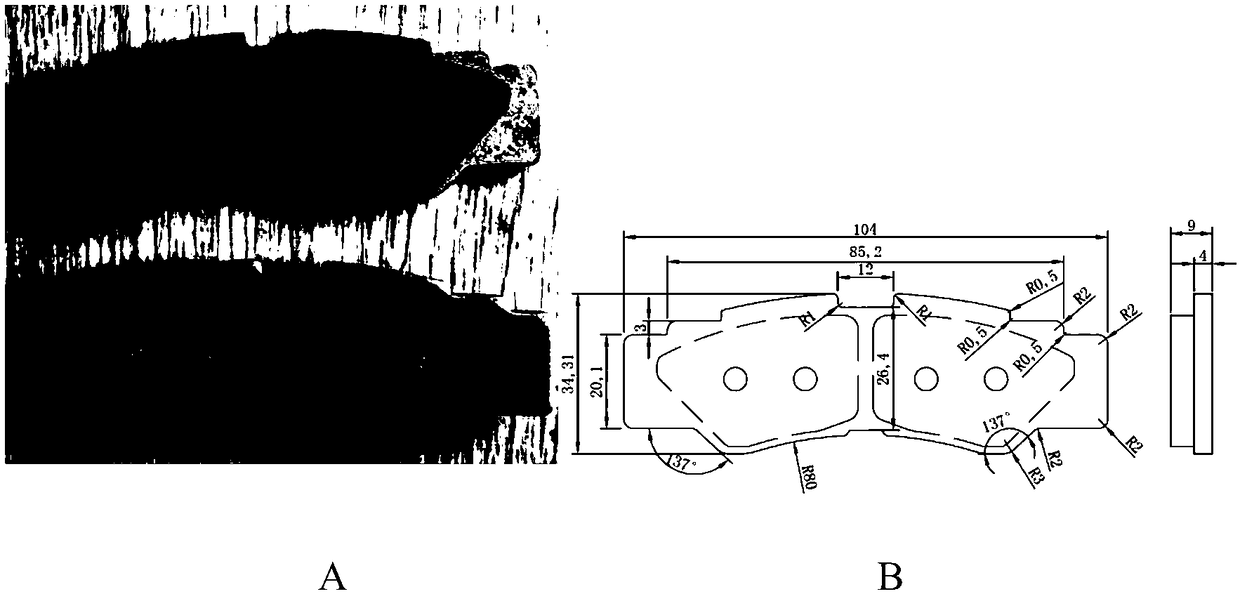

[0047] preparation figure 2 A certain type of mountain bike brake pad shown includes the following steps:

[0048] Step 1, batching according to the proportion, 35 parts of the main component 300 mesh dendritic electrolytic copper powder, 3 parts of 30 micron tin powder, 25 parts of 300 mesh copper-tin composite powder, 3 parts of auxiliary component 250 mesh reduced iron powder, 1 part each of 400-mesh titanium powder and zinc powder, 12 parts of 300-micron scaly graphite powder for lubricating components, 2.5 parts of 200-mesh molybdenum disulfide powder, 2 parts of 100-mesh pore-forming agent calcium carbonate, and 100-mesh friction component without edges and corners 2.0 parts of kaolin, 3 parts of 100 mesh non-angular feldspar powder, 3 parts of 100 mesh non-angular zircon powder, 2.5 parts of 100 mesh non-angular high-purity mullite, 2 parts of 200 mesh vermiculite, 100 mesh silicic acid Aluminum hollow ball 2 parts. ready to go.

[0049] Step 2, mixing and granulati...

Embodiment 3

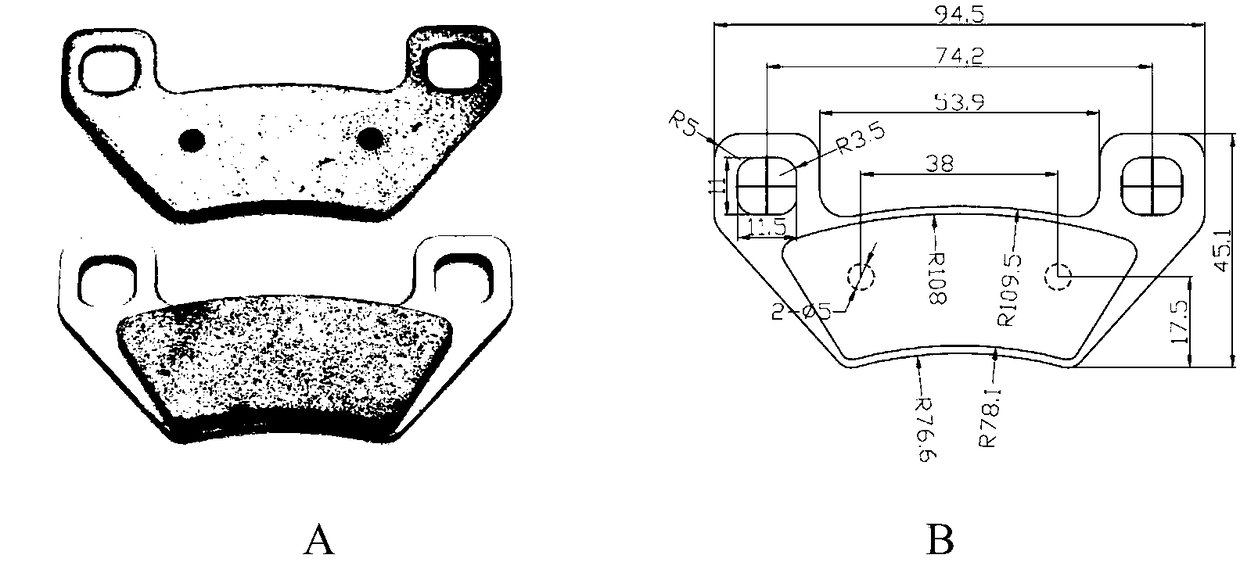

[0057] preparation image 3 The brake pads of a certain model of ATV shown include the following steps:

[0058] Step 1, batching according to the proportion, 37 parts of the main component 280 mesh dendritic electrolytic copper powder, 3 parts of 50 micron tin powder, 27 parts of 300 mesh copper-tin composite powder, 2 parts of auxiliary component 260 mesh reduced iron powder, 1.5 parts each of 300 mesh zinc powder and molybdenum powder, 11 parts of 330 micron scaly graphite powder for lubricating components, 2.5 parts of 200 mesh molybdenum disulfide powder, 1.5 parts of 100 mesh pore-forming agent calcium carbonate, and 100 mesh friction components without edges and corners 2.5 parts of kaolin, 2.5 parts of 100 mesh non-angular feldspar powder, 2.5 parts of 100 mesh non-angular zircon powder, 1.5 parts of 100 mesh non-angular high-purity mullite, 2.5 parts of 200 mesh vermiculite, 100 mesh alumina Hollow ball 1.5 parts; ready to place.

[0059] Step 2, mixing and granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com