Nanotube array/nanowire composite structure, preparation method, quantum dot sensitized composite structure and application

A technology of quantum dot sensitization and nanotube array, applied in the field of quantum dot sensitization composite structure, preparation, nanotube array/nanofilament composite structure, can solve the problem of small light absorption area, small effective specific surface area of nanotube structure, limitation application and other issues, to achieve the effect of increasing the refractive index, huge specific surface area, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

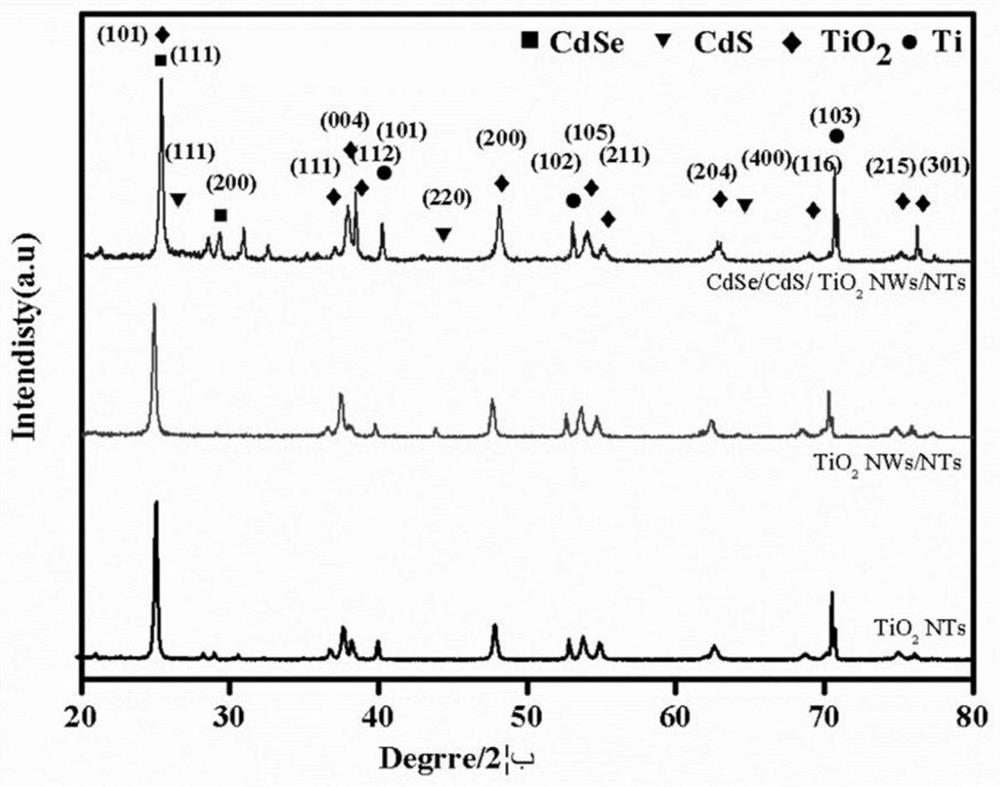

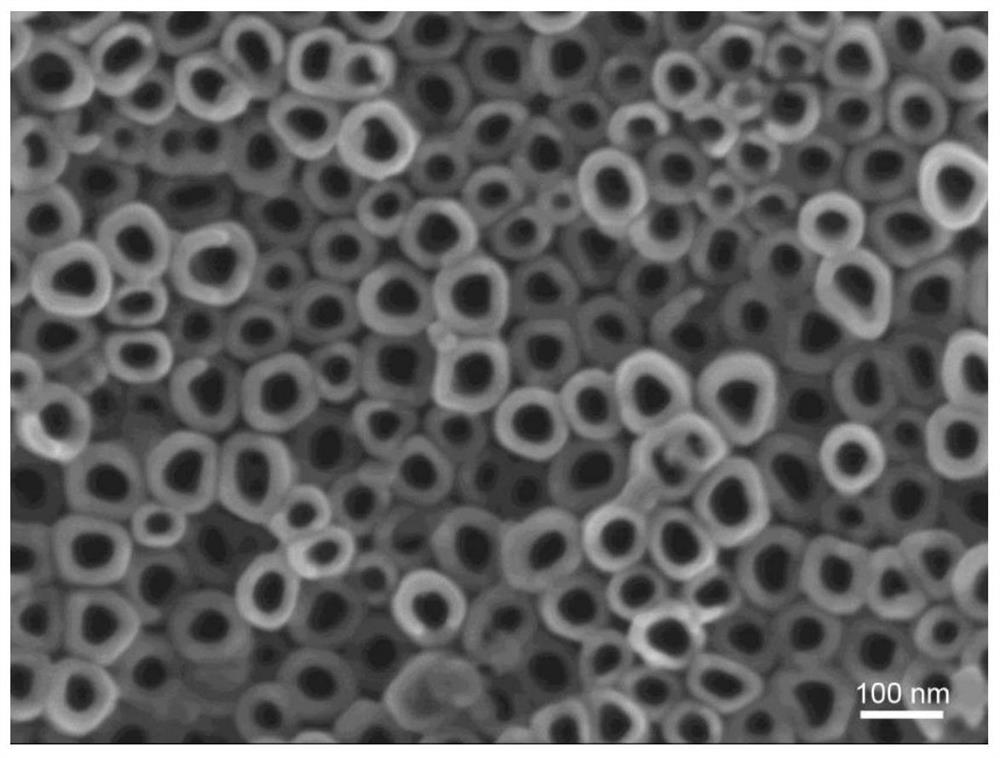

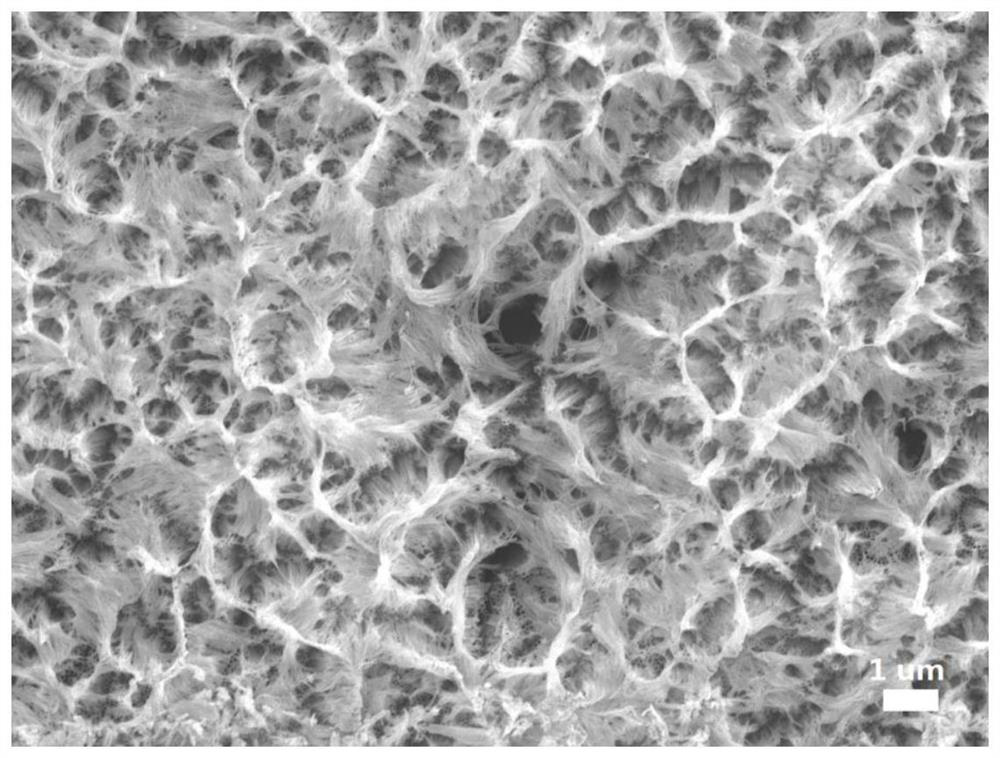

[0044] An in-situ preparation of TiO 2 The method for NWs / NTs composite structure, is characterized in that, comprises the steps:

[0045] (1) Preparation of TiO 2 NWs / NTs. The cut Ti slices (3 cm × 3 cm × 0.01 cm) were ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min, and then dried. Put the cleaned Ti sheet in the polishing solution (HF:HNO 3 :H 2 (O=1:4:10) was polished for 40s, ultrasonicated in ethanol and deionized water for 10min respectively, and then the Ti sheet was anodized using a DC stabilized power supply, with the Ti sheet as the working electrode (anode), and the Pt sheet electrode As the cathode, the electrolyte contains 0.3wt% NH 4 F +2vol%H 2 O in 120mL ethylene glycol solution, the entire anodic oxidation process lasted 5h at a voltage of 55V. After the electrolysis, the samples were rinsed with ethanol and deionized water several times, dried, and then placed in a tube furnace, heated to 500 °C at a heating rate of 5 °C / min...

Embodiment 2

[0047] CdS quantum dots sensitized TiO 2 NWs / NTs (CdS / TiO 2 The preparation method of NWs / NTs) structure is characterized in that, comprises the steps:

[0048] (1) TiO 2 The preparation method of NWs / NTs is the same as the step (1) of Example 1.

[0049] (2) Using the continuous ion layer adsorption and reaction (SILAR) chemical bath precipitation method, the TiO obtained in step (1) 2 The front of the NWs / NTs sample was immersed in a solution containing 0.1mol·L -1 CdCl 2 In the ethanol solution, the immersion time was 5min, then the sample was taken out and rinsed with ethanol for 5 times and then dried; then the sample was -1 Na 2 S in a methanol solution, immersed for 5 min, the sample was taken out and rinsed with methanol for 5 times and then dried; finally, the sample was placed in a vacuum environment at 350°C for 1 h, and a sample CdS(1cycle) / TiO 2 NWs / NTs. The deposition process can also be repeated many times, usually 3 to 5 deposition cycles.

Embodiment 3

[0051] CdSe Quantum Dots Sensitized TiO 2 NWs / NTs (CdSe / TiO 2 The preparation method of NWs / NTs) structure is characterized in that, comprises the steps:

[0052] (1) TiO 2 The preparation steps of NWs / NTs are the same as step (1) of Example 1.

[0053] (2) the sample TiO obtained in step (1) 2 NWs / NTs were used as working electrodes, and electrochemical deposition was carried out on a CHI 760E electrochemical workstation, and the electrolyte was composed of (10mmol CdCl 2 +0.2mmol SeO 2 +2 mmol Na 2 SO 4 ) dissolved in 120mL deionized water, the Pt sheet is used as the counter electrode, the calomel electrode is used as the reference electrode, the applied voltage is -0.7V, and the deposition time is 10-40 min. After the deposition was completed, the sample was rinsed with deionized water and alcohol for 5 times, dried at 60°C, and then placed in a vacuum environment for high temperature treatment at a temperature of 350°C, holding time 1h, and cooled in the furnace to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com