Ice melting agent for deicing of electric pole and preparation method thereof

An ice-melting agent and electric pole technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of slow ice-melting rate, inability to form a protective film, poor ice-melting effect, etc. The speed, the ice melting effect is remarkable, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

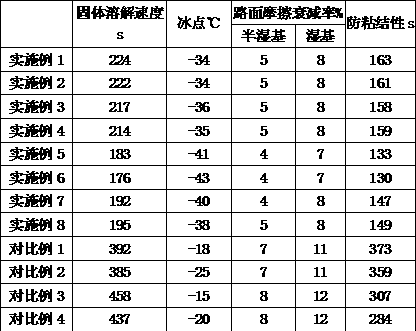

Examples

Embodiment 1

[0031] An ice melting agent for deicing electric poles is made of the ingredients shown in Table 1, and the modified epoxy resin is made of the ingredients shown in Table 2.

[0032] Wherein, the compatibilizer is maleic anhydride, the stripping agent is tetrabutylammonium hydroxide, and the corrosion inhibitor is sodium gluconate.

[0033] The method for preparing an ice melting agent for deicing electric poles includes the following steps:

[0034] S1: Put the modified epoxy resin and 1 / 2 part by weight of water in a magnetic stirrer at 50-55°C and stir for 15 minutes at 300r / min, then add multi-walled carbon nanotubes and the remaining 1 / 2 Parts by weight of water, keep the temperature constant, adjust the speed to 200r / min, and stir for 60min to obtain mixed liquid I;

[0035] S2: Put 1,2-propanediol, glycerol, carbonamide and sodium acetate in a reaction kettle, and pour nitrogen into it. The pressure inside the reaction kettle is 0.8-1.2MPa, and the pressure is 300r / min at 70-80...

Embodiment 2

[0043] The components and amounts of an ice melting agent for deicing electric poles are the same as those in Example 1. The modified epoxy resin is made of the components shown in Table 2.

[0044] The compatibilizer is mica powder with a particle size ≤ 10 μm. The content of chemical components in the mica powder is: silica 45-49%, aluminum oxide 30-35%, sodium oxide 1.2-2%, potassium oxide 2.5-3.3%, magnesium oxide 1.5-2%, three Iron oxide is 2-4%, water is 0.1-0.15%, and the rest are unavoidable impurities.

[0045] The stripping agent is 1-octyl-3-methylimidazole chloride. The corrosion inhibitor is thiourea.

[0046] The method for preparing an ice melting agent for deicing electric poles is the same as in Example 1.

[0047] The preparation method of the modified epoxy resin is the same as in Example 1.

Embodiment 3

[0049] An ice-melting agent for deicing electric poles is made of the components shown in Table 1. The components and the amounts in the modified epoxy resin are the same as in Example 2.

[0050] Wherein, the compatibilizer is maleic anhydride, the release agent is tetrabutylammonium hydroxide, and the corrosion inhibitor is aluminum sulfate.

[0051] The method for preparing an ice melting agent for deicing electric poles includes the following steps:

[0052] S1: Put the modified epoxy resin and 1 / 2 parts by weight of water in a magnetic stirrer at 50-55°C and stir at 350r / min for 12 minutes, then add multi-walled carbon nanotubes and the remaining 1 / 2 Parts by weight of water, keep the temperature constant, adjust the speed to 250r / min, stir for 50min, and obtain the mixed solution I;

[0053] S2: Put 1,2-propanediol, glycerol, carbonamide and sodium acetate in a reaction kettle, and purge nitrogen. The pressure in the reaction kettle is 0.8-1.2MPa, and the temperature is 350r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com