Co-sintering preparation method for flyash-based ceramic microfiltration membrane

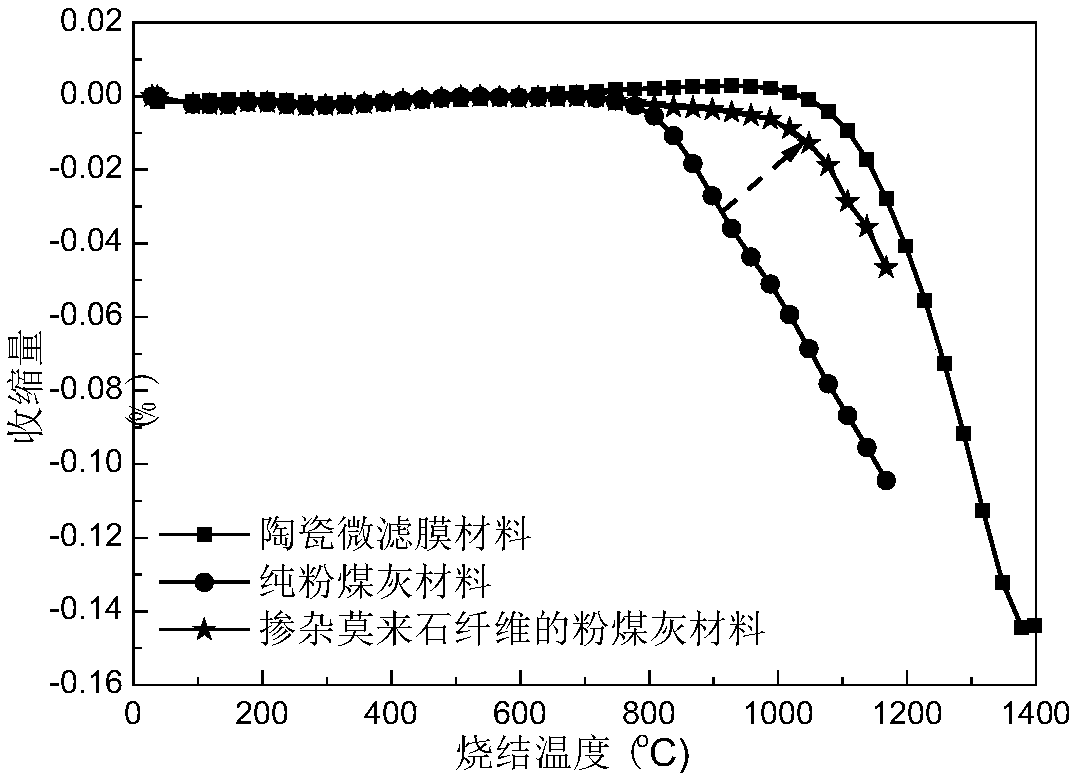

A technology for ceramic microfiltration and fly ash, which is applied in the production of ceramic materials, clay products, applications, etc., can solve the problems of high preparation cost of ceramic membranes, and achieve the effect of reducing the cost of raw materials and energy consumption of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, 100-mesh sieves were used to classify the fly ash, and the classified fly ash and alumina whiskers (the mass ratio of rigid oxide whiskers to fly ash was 1:6) were mixed for 1 min, and then mixed Add 2% glycerin to the final powder to the total mass of fly ash and alumina whiskers for mixing, mud refining, and dry pressing to prepare a green sheet fly ash / whisker carrier, and control the pressure At 5Mpa, the residence time is 60s. Secondly, alumina powder with an average particle size of 300nm, a certain amount of sulfuric acid, and a certain amount of polyvinyl alcohol are prepared into a stable film-forming solution under the action of an ultrasonic instrument. The mass fraction of alumina in the prepared film-forming solution 5wt.%, the mass fraction of the thickener is controlled at 20wt.%, and the pH value of the final prepared film-forming solution is 2. The film-forming solution was sprayed on the green sheet-type fly ash / whisker carrier by spray gun spr...

Embodiment 2

[0025] First, a 1000-mesh sieve was used to classify the fly ash, and the classified fly ash and silicon carbide whiskers (the mass ratio of the rigid oxide whiskers to the fly ash was 1:10) were mixed for 60 minutes by conventional stirring. Add polyvinyl alcohol accounting for 10% of the total mass of fly ash and alumina whiskers to the mixed powder for mixing, mud refining, and dry pressing to prepare green flake fly ash / whiskers For the carrier, the pressure is controlled at 30Mpa, and the residence time is 5s. Secondly, alumina powder with an average particle size of 1000nm, a certain amount of hydrochloric acid, and a certain amount of polyethylene glycol are prepared into a stable film-making solution under the action of an ultrasonic instrument. The quality of alumina in the prepared film-making solution The fraction is 35wt.%, the mass fraction of the thickener is controlled at 5wt.%, and the pH value of the final prepared membrane solution is 4. The film-forming sol...

Embodiment 3

[0027] First, 300-mesh sieves were used to classify the fly ash, and the classified fly ash and mullite whiskers (the mass ratio of rigid oxide whiskers to fly ash was 1:8) were mixed for 5 minutes by conventional stirring. , adding polyvinyl alcohol accounting for 4% of the total mass of fly ash and alumina whiskers to the mixed powder for mixing, refining mud, and preparing green flake fly ash / crystal whiskers through a dry pressing process. The carrier must be used, the pressure is controlled at 20Mpa, and the residence time is 20s. Secondly, alumina powder with an average particle size of 300nm, a certain amount of nitric acid, and a certain amount of methylcellulose are formulated into a stable film-forming solution under the action of an ultrasonic instrument. The quality of alumina in the prepared film-forming solution The fraction is 20wt.%, the mass fraction of the thickener is controlled at 14wt.%, and the pH value of the final prepared membrane solution is 2. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com