Preparation method of carbon nanoparticles and carbon dots using activated carbon as precursor

A carbon nanoparticle and activated carbon technology, applied in nanocarbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor universality of activated carbon, large loss of activated carbon, and decreased adsorption capacity, and achieve social and economic benefits. Obvious, functional design is strong, and the effect of reuse is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing carbon nanoparticles and carbon dots with activated carbon as a precursor, comprising the following steps:

[0033] a, take (collect) the deactivated coal-based activated carbon with a particle size of about 3 mm used in sewage purification in chemical and chemical plants, without cleaning, directly place it in a blast drying oven at 120 ° C for 2 hours;

[0034] b. Using a ball mill to grind the above-mentioned activated carbon particles to a powder with a particle size distribution of 40-60 nm;

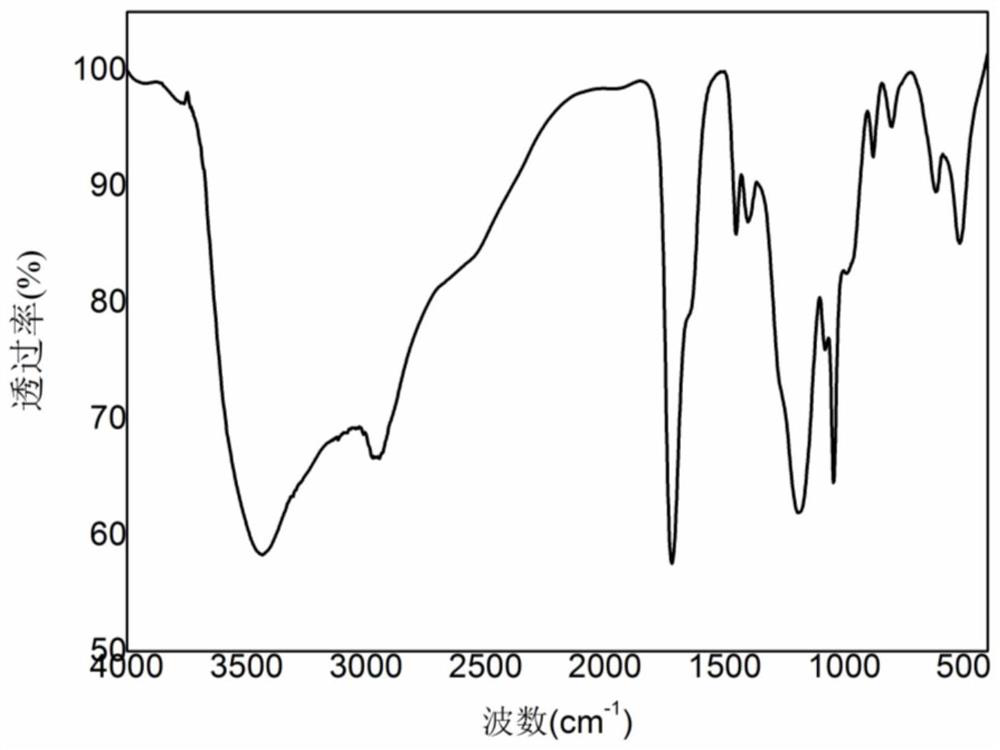

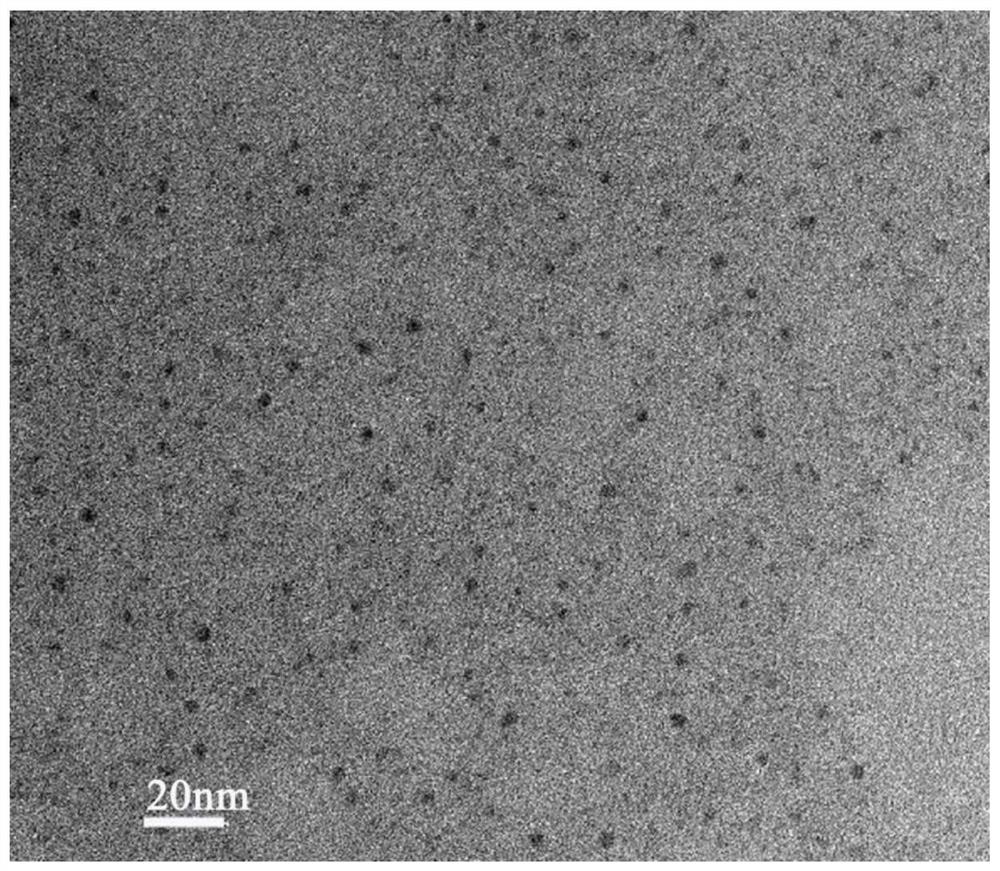

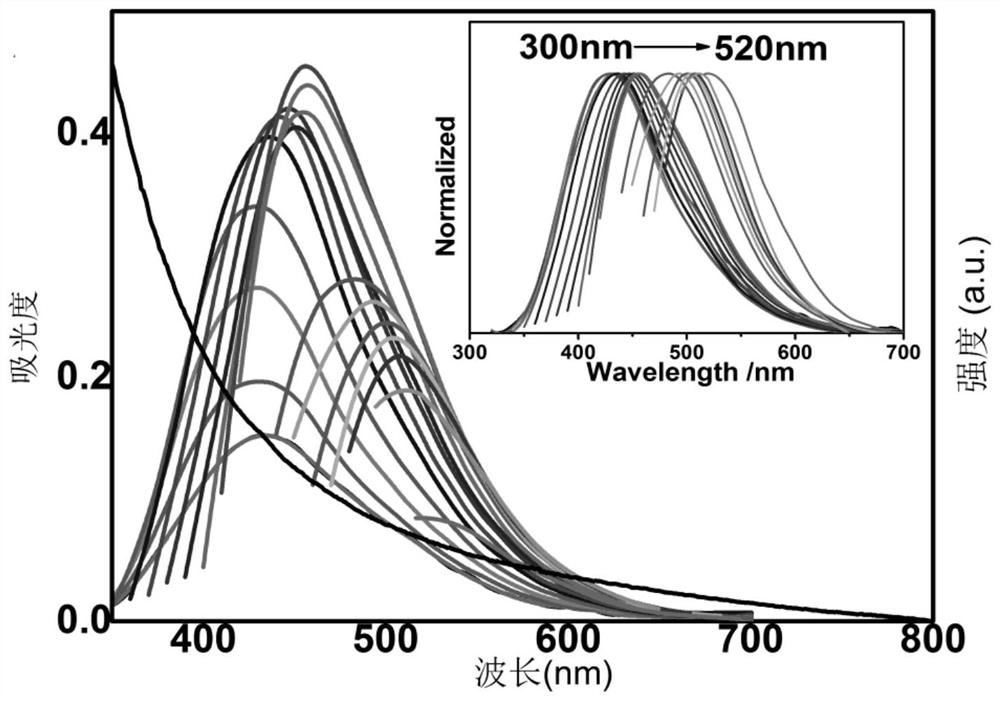

[0035] c, the preparation mass percentage concentration is the nitric acid aqueous solution of 31%, 5 mass parts of powdered gacs are added to 200 mass parts of nitric acid aqueous solution and stir at room temperature for 10 hours, then be warming up to 120 ℃ of constant temperature reaction 48 hours, obtain the material after reaction; After the material was left to stand for 12 hours, the supernatant part of the extraction was the crude product conta...

Embodiment 2

[0040] A method for preparing carbon nanoparticles and carbon dots with activated carbon as a precursor, comprising the following steps:

[0041] a. Take (collect) the deactivated husk-based activated carbon with a diameter of about 0.6-2 mm that has been used for drinking water treatment, and directly place it in a blast drying oven at 105 ° C for 6 hours without cleaning;

[0042] b. Using a ball mill to grind the above-mentioned activated carbon particles to a powder with a particle size distribution of 20-40nm;

[0043] c, the preparation mass percentage concentration is the nitric acid aqueous solution of 31%, 5 mass parts of powdered gacs are added to 200 mass parts of nitric acid aqueous solution and stir at room temperature for 8 hours, then be warming up to 120 ℃ of constant temperature reaction 48 hours, obtain the material after reaction; After the material was left to stand for 12 hours, the supernatant part of the extraction was the crude product containing carbon...

Embodiment 3

[0048] A method for preparing carbon nanoparticles and carbon dots with activated carbon as a precursor, comprising the following steps:

[0049] a, take (collect) the sulfur-containing powdered activated carbon that has been used for the treatment of oil refinery wastewater, and directly place it in a blast drying oven at 105° C. for 6 hours without cleaning;

[0050] b. Using a ball mill to grind the above-mentioned activated carbon particles to a powder with a particle size distribution of 20-40nm;

[0051] c, the preparation mass percentage concentration is the nitric acid aqueous solution of 31%, 5 mass parts of powdered gacs are added to 200 mass parts of nitric acid aqueous solution and stir at room temperature for 8 hours, then be warming up to 120 ℃ of constant temperature reaction 48 hours, obtain the material after reaction; After the material was left to stand for 12 hours, the supernatant part of the extraction was the crude product containing carbon nanoparticles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com