Magnetic sludge biochar, preparation method therefor and application of magnetic sludge biochar

A biochar and sludge technology, applied in water/sludge/sewage treatment, water pollutants, pyrolysis treatment of sludge, etc., can solve problems such as poor adsorption and removal capacity, limited adsorption sites, and secondary pollution of water bodies. , to achieve the effect of easy operation, reduction of preparation cost, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of magnetic sludge biochar and preparation method thereof, and the method is carried out according to the following steps:

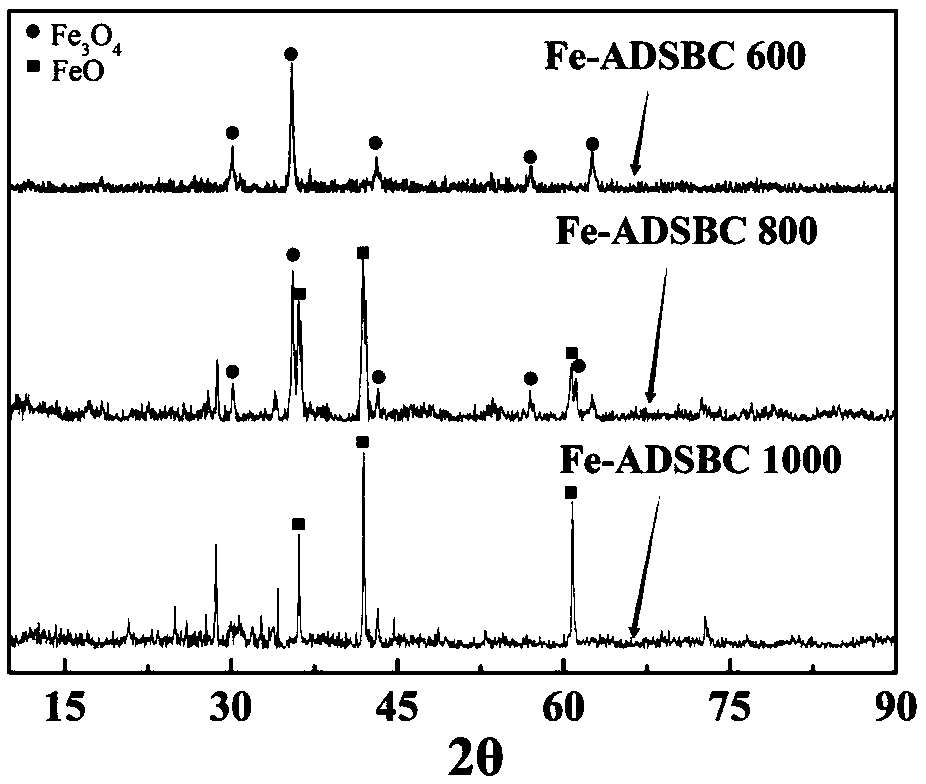

[0034] After the sludge is dehydrated by the zero-valent iron-persulfate system (add 0.375g of potassium persulfate and 3g of zero-valent iron (iron powder) to each gram of sludge and mix it in an air bath at 25°C for 0.5 hours), send it into High-temperature tube furnace, pyrolysis at 1000°C under nitrogen atmosphere, the temperature of the high-temperature pyrolysis furnace is raised from 25°C to 1000°C at a heating rate of 15°C / min, and kept at 1000°C for 90 minutes, and the pyrolyzed magnetic contamination The mud biochar is passed through a 200-mesh sieve. The SEM, XRD and XPS images observed under the scanning electron microscope for the obtained magnetic sludge biochar are as follows: Figure 1-3 shown. Depend on Figure 1-3 It can be seen that the magnetic sludge biochar obtained at 1000℃ mainly co...

Embodiment 2

[0036]The present embodiment provides a kind of magnetic sludge biochar and preparation method thereof, and the method is carried out according to the following steps:

[0037] After the sludge is dehydrated by the zero-valent iron-persulfate system (add 0.375g of potassium persulfate and 3g of zero-valent iron (iron powder) to each gram of sludge and mix it in an air bath at 25°C for 0.5 hours), send it into High-temperature tube furnace, pyrolysis at 800°C under nitrogen atmosphere, the temperature of the high-temperature pyrolysis furnace was raised from 25°C to 800°C at a heating rate of 15°C / min, and kept at 800°C for 90 minutes, and the pyrolyzed magnetic contamination The mud biochar is passed through a 200-mesh sieve. The SEM, XRD and XPS images observed under the scanning electron microscope for the obtained magnetic sludge biochar are as follows: Figure 1-3 shown. Depend on Figure 1-3 It can be seen that the magnetic sludge biochar obtained at 800°C mainly conta...

Embodiment 3

[0039] The present embodiment provides a kind of magnetic sludge biochar and preparation method thereof, and the method is carried out according to the following steps:

[0040] After the sludge is dehydrated by the zero-valent iron-persulfate system (add 0.375g of potassium persulfate and 3g of zero-valent iron (iron powder) to each gram of sludge and mix it in an air bath at 25°C for 0.5 hours), send it into High-temperature tube furnace, pyrolyze at 600°C under nitrogen atmosphere, heat up from 25°C to 600°C at a heating rate of 15°C / min, and keep at 600°C for 90 minutes, the pyrolyzed magnetic contamination The mud biochar is passed through a 200-mesh sieve. The SEM, XRD and XPS images observed under the scanning electron microscope for the obtained magnetic sludge biochar are as follows: Figure 1-3 shown. Depend on Figure 1-3 It can be seen that the magnetic sludge biochar obtained at 600°C mainly contains Fe3O4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com