Delafossite structure CuFeO2 powder and preparation method and application thereof

A kind of copper iron ore, powder technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry and other directions, can solve problems such as unfavorable large-scale industrial production, complex process, long cycle, etc., to achieve convenient industrial production, good repeatability, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

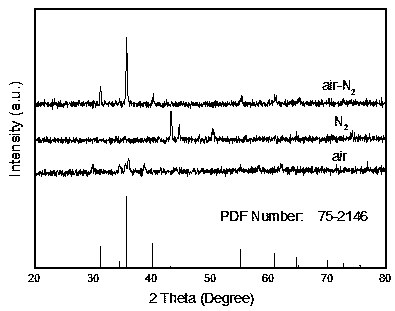

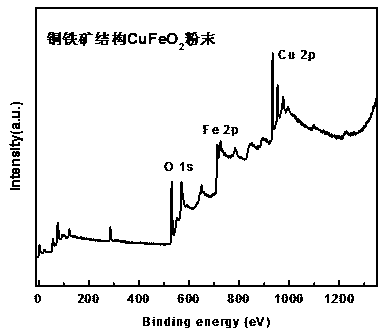

[0032] This embodiment provides a delafossite structure CuFeO 2 Method of powder preparation. details as follows.

[0033] (1) 0.01 mol of Cu (NO 3 ) 2 ·3H 2 O and 0.01 mol of Fe (NO 3 ) 3 9H 2 O was dissolved in deionized water (40 mL), then 0.02 mol of citric acid and 0.5 g of PEG20000 were added, and the whole mixture was fully stirred to dissolve to obtain Cu-containing 2+ and containing Fe 3+ aqueous solution; then slowly add NH 3 ·H 2 O, adjust the pH value of the solution in the range of 2-3, and obtain the reaction precursor after fully stirring.

[0034] (2) The precursor solution was dried in a drying oven at 110 °C for 24 h, the obtained powder was ground with an agate mortar, and then the sample was placed in an atmosphere furnace, and the temperature was raised to Incubate at 1100°C for 5 h, and feed in N at a flow rate of 200 sccm 2 after N 2 Cool with the furnace in the atmosphere to obtain the sample.

Embodiment 2

[0036] This embodiment provides a delafossite structure CuFeO 2 The preparation method of the powder, except that the consumption of citric acid is 0.04mol, all the other steps and conditions are consistent with Example 1.

[0037] This example can successfully prepare delafossite structure CuFeO 2 powder.

Embodiment 3

[0039] This embodiment provides a delafossite structure CuFeO 2 The preparation method of the powder is consistent with that of Example 1 except that 1 g of PEG2000 is selected.

[0040] This example can successfully prepare delafossite structure CuFeO 2 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com