A kind of preparation method of positive plate sandwich structure of li-s battery

A technology of sandwich structure and battery positive electrode, applied in battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve problems such as unfavorable lithium-sulfur battery capacity retention and rate performance, consumption of positive electrode active materials, and failure to meet application requirements. , to achieve the effect of inhibiting the loss of lithium polysulfide, inhibiting the loss of dissolution, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

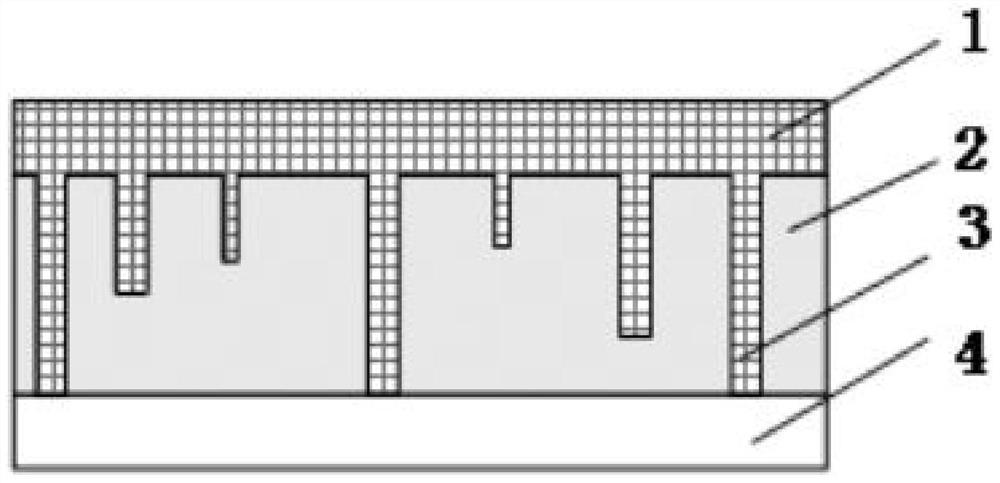

[0045] With PVDF as binder, conductive carbon black SP as conductive agent, NMP as solvent, and sulfur-carbon composite powder with a sulfur mass content of 90% as active material, according to active material: conductive agent: binder ( Mass ratio) = x: y: (1-x-y) (x = 60 ~ 70, y = 10 ~ 30): the ratio of the remainder, binder: solvent (mass ratio) = 1: (5 ~ 30) ratio The slurry was mixed and ground with NMP, scraped and coated on aluminum foil or copper foil current collector, and then dried in a vacuum oven at 60°C to 75°C for 48 to 72 hours to obtain a positive electrode sheet.

[0046] The positive electrode sheet is placed in an acetone saturated steam chamber at 30° C. to 40° C. for 0.5 to 1 hour of wetting treatment.

[0047] Put the positive electrode sheet into the anode position of the magnetron sputtering chamber through the feeding bin, and keep it in a high vacuum state for 30-60 minutes.

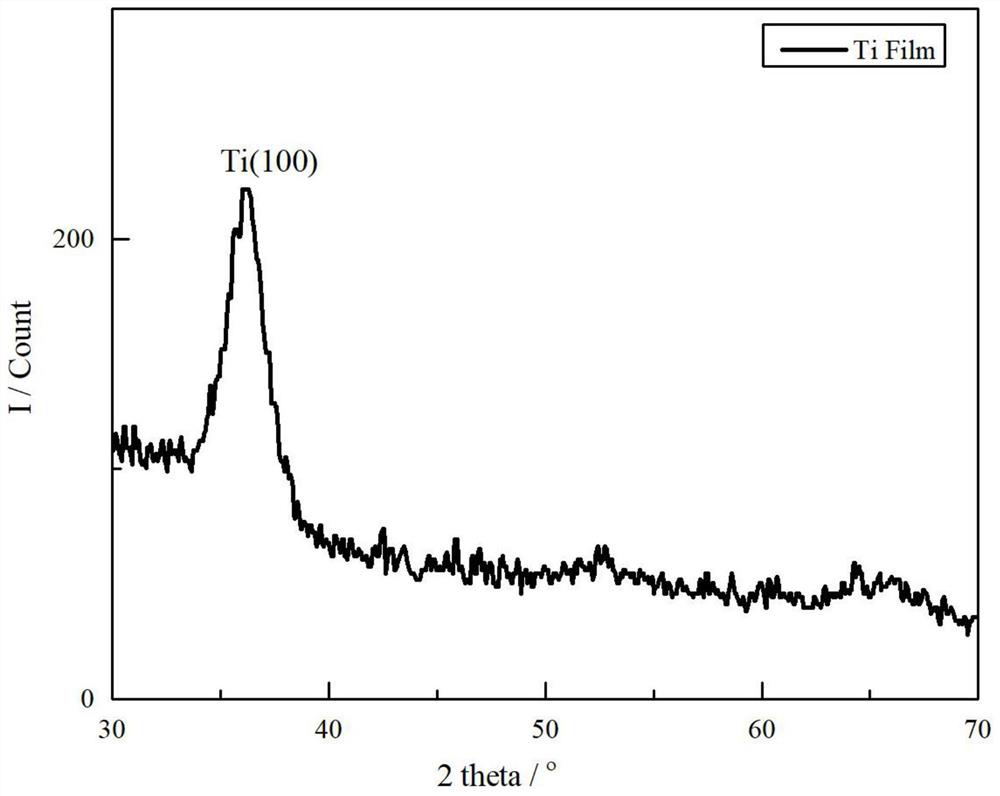

[0048] The metal titanium film is deposited for 20 minutes by using a spu...

Embodiment 2

[0050] With PVDF as binder, flake graphite as conductive agent, NMP as solvent, and high-purity sublimated sulfur as active material, according to active material: conductive agent: binder (mass ratio) = x: y: (1- The ratio of x-y) (x=70, y=10~25), using binder:solvent (mass ratio)=1:(9~30) ratio solution as dispersant, mixing and grinding to obtain slurry, scrape coating on aluminum foil or on a current collector of a conductive carbon film, and then dried in a vacuum oven at 60° C. to 75° C. for 24 to 48 hours to obtain a positive electrode sheet.

[0051] The positive electrode sheet was placed in an ethanol saturated steam room at room temperature for wet treatment for 0.5-1 hour.

[0052] The positive electrode piece is placed in the anode position of the magnetron sputtering chamber, and kept in a high vacuum state for 30-60 minutes.

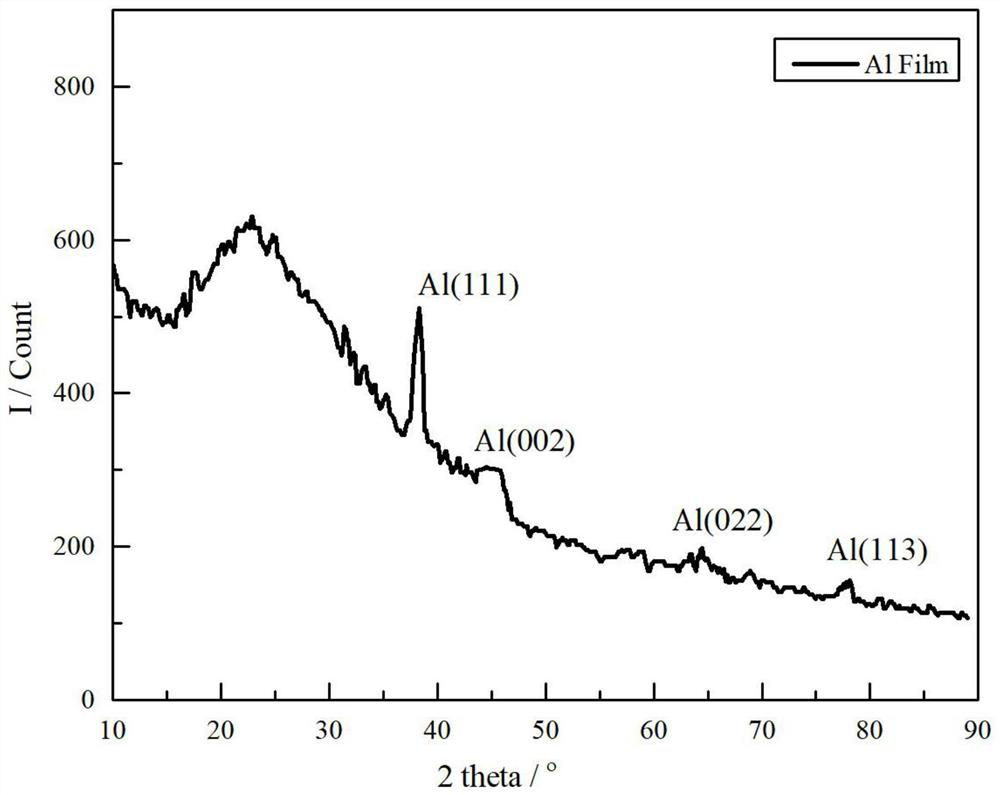

[0053] Aluminum target is used, argon gas is used as plasma gas source, sputtering power is 30-60W, vacuum chamber pressure is 10 -4 Pa,...

Embodiment 3

[0055] With polyvinyl alcohol as binder, acetylene black as conductive agent, NMP as solvent, and high-purity sublimated sulfur as active material, according to active material: conductive agent: binder (mass ratio) = 70: (10~ 20): The ratio of the remaining amount is mixed and ground according to the ratio of binder: solvent (mass ratio) = 1: (2 ~ 10) to obtain a slurry, which is scraped on the aluminum foil or copper foil current collector, and then heated at 60 ° C ~ Dry in a vacuum oven at 75° C. for 24 to 48 hours to obtain a positive electrode sheet.

[0056] The positive electrode sheet is placed in a saturated steam chamber of ethylene glycol monomethyl ether at 40°C to 50°C for 0.5 to 1 hour of wetting treatment.

[0057] Put the positive electrode sheet into the anode position of the magnetron sputtering chamber in a high vacuum state through the feeding bin, and keep it for 30-60 minutes.

[0058] Using a titanium-aluminum alloy target (with a mass fraction of 10-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com