Papermaking black liquid lignin content detection method

A paper-making black liquor and detection method technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of inability to achieve accurate detection, and achieve the effects of short detection time, high accuracy and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 1. Preparation of lignin samples. 5g of papermaking black liquor lignin sample and about 2g of lignin sample to be tested were dried at 105°C to constant weight, ground into fine powder with a mortar, and passed through a 100-mesh sieve.

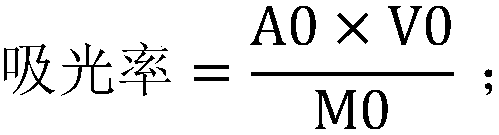

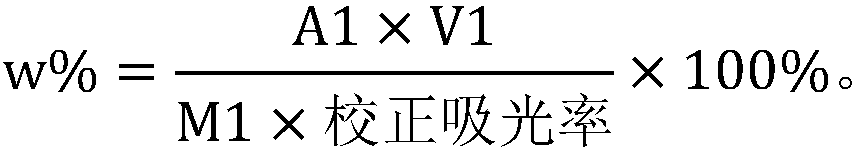

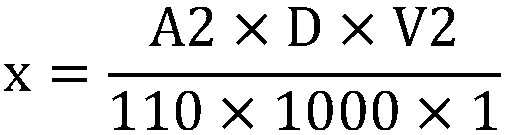

[0033] 2. Calculation of solution absorbance Absorptivity. Prepare acidified acetyl bromide solution, acetyl bromide: glacial acetic acid = 1:3 (V:V). Use a pressure-resistant bottle with a polytetrafluoroethylene cover as a digestion and hydrolysis bottle to take 0.0005-0.0030 g of dry lignin powder from papermaking black liquor, and add 5 ml of acidified acetyl bromide solution. Tighten the PTFE stopper, keep warm in a 70°C water bath for 1 hour and 45 minutes, and rotate gently every 30 minutes.

[0034] Cool in an ice-water bath, transfer to a 100ml volumetric flask, add 10ml of glacial acetic acid, 4.5ml of 4N sodium hydroxide and 1.5ml of 5N hydroxylamine hydrochloride, mix well after each addition, and finally dilute to 100ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com