Low-chucking fin for cooler

A technology of coolers and fins, applied in the field of low-elongation resistance fins for coolers, can solve the problems of ineffective coupling of the operating environment, complex fin-shaped design structure, etc., to solve the problem of thermal stability, prolong service time, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

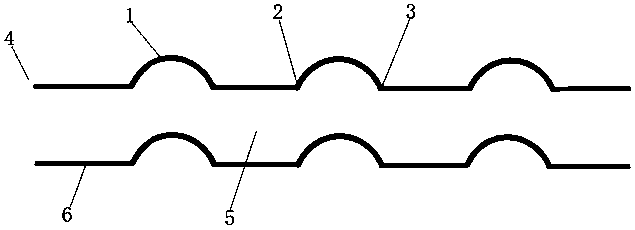

[0043] see figure 1 , a low-resistance semicircular embossed fin for a cooler, comprising a semicircular structure fin 6 and an embossed 1, the opening direction of the embossed 1 is consistent, and is arranged at intervals on the wing-shaped side of the fin 6, and the embossed The height of the mark 1 is 1 / 6 to 1 / 2 of the height of the section of the fin channel, and a plurality of fins 6 are arranged in parallel to form an air flow channel 5 between the fins 6. Internally generate vibration and disturbance to the air medium, and achieve ideal heat mixing effect and heat transfer capacity under the condition of low internal resistance.

[0044] The distance between the raised marks 1 is 6-12mm, the distance between the raised marks 1 near the entrance 4 of the fin channel and the entrance 4 of the fin channel is 10-15mm, and the arrangement density of the semicircular raised marks can be adjusted. The basis for adjustment is the total pressure level of the fan. If the total ...

Embodiment 2

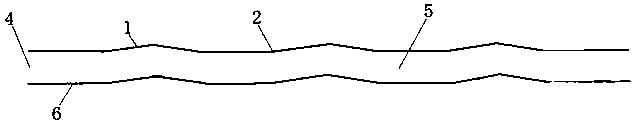

[0072] see figure 2 , a cooler with low extension resistance pressure prismatic embossed fins, including fins 6, a plurality of fins 6 are arranged in parallel, air flow channels 5 are formed between the fins 6, and the fin-shaped sides of the fins 6 are arranged at intervals There are convex marks 1 with the same opening direction, the height of the convex marks 1 is 1 / 6~1 / 2 of the section height of the air flow channel 5, and the convex marks 1 are used to generate vibration and disturbance to the air medium in the air flow channel 5 Function, to achieve ideal heat mixing effect and heat transfer capacity under the condition of low internal resistance.

[0073] Convexity 1 is an obtuse prismatic structure, which is used to change the cross section of the flow channel. The convexity is selected with an appropriate shape kurtosis to form an intermittent nozzle effect and turbulence effect, which makes the air flow disturbance of the cold medium and destroys the effect of the ...

Embodiment 3

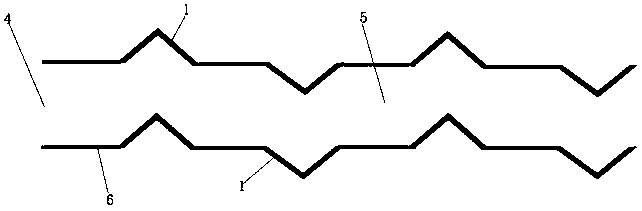

[0091] see image 3 , a low-resistance symmetrical embossed fin for a cooler, including fins 6, a plurality of fins 6 are arranged in parallel, and air flow channels 5 are formed between the fins 6, and the wing-shaped sides of the fins 6 are arranged at symmetrical intervals Convex marks 1 with opposite opening directions. The height of the protruding marks 1 is 1 / 6~1 / 2 of the section height of the air channel 5. The protruding marks 1 are used to excite and disturb the air medium in the air channel 5. Realize the ideal heat mixing effect and heat exchange capacity under the condition of low internal resistance.

[0092] Protrusion 1 is a triangular prism structure, which is used to change the cross section of the flow channel. The convex mark selects an appropriate shape kurtosis to form an intermittent nozzle effect and turbulence effect, which makes the air flow disturbance of the cold medium and destroys the effect of the boundary laminar flow , allowing the air stream t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com