Sausage casing dryer

A technology for dryers and casings, which is applied in drying, drying machines, sausage casings, etc., can solve problems such as unreasonable device structure, increased labor intensity of operators, unfavorable operation of operators, etc., to achieve optimal drying quality, Improve drying efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

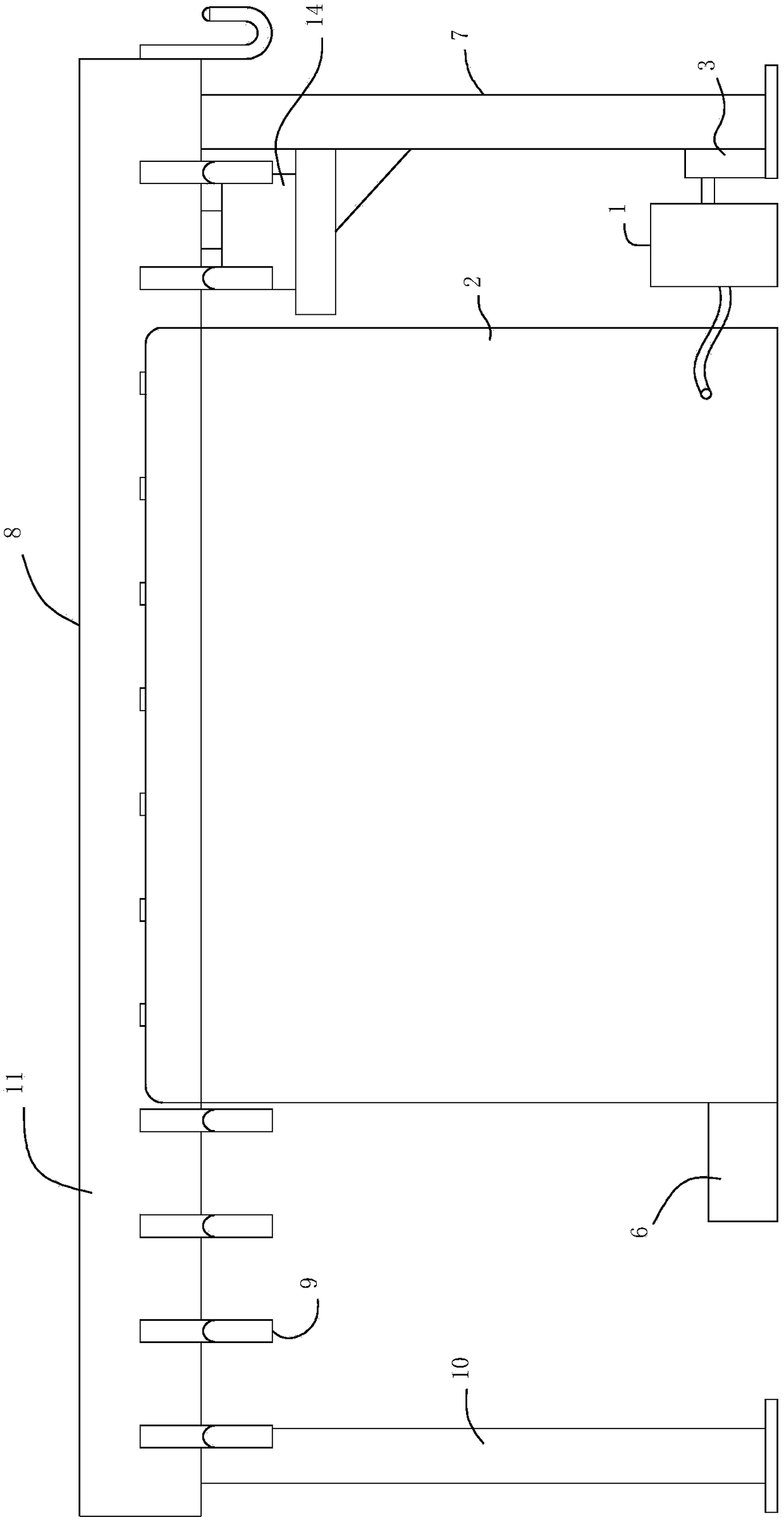

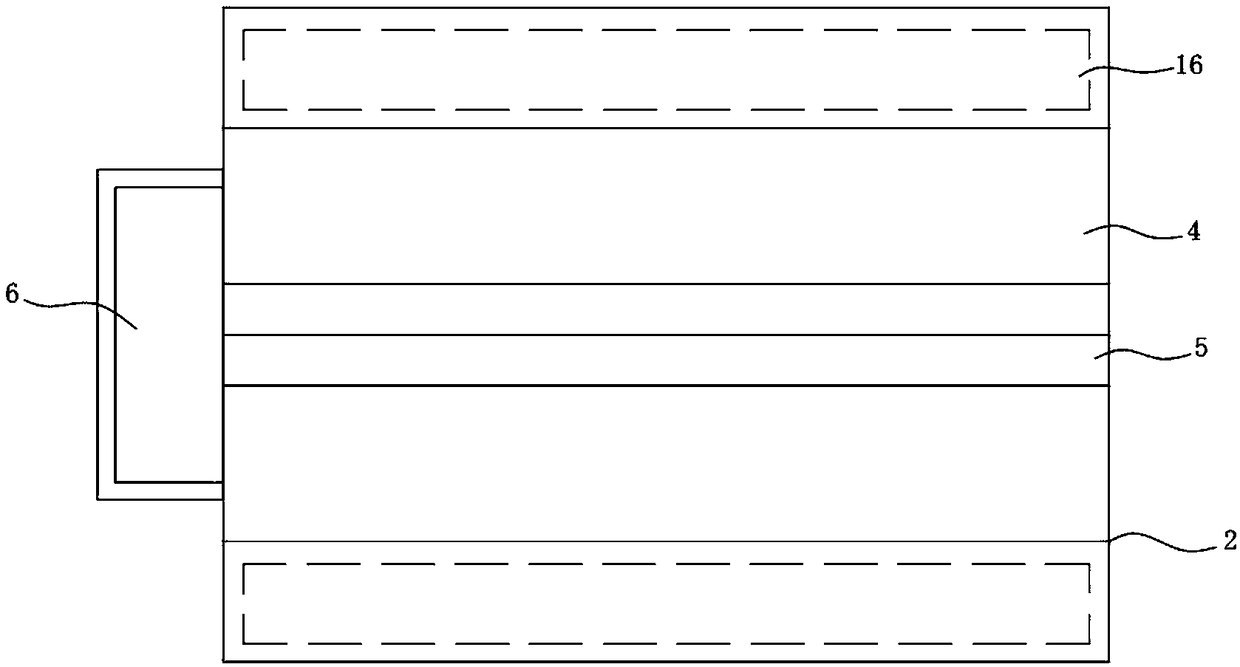

[0027] Such as figure 1 , figure 2 , image 3 , a casing dryer, comprising an air heating chamber 1 and a drying chamber 2, the air heating chamber 1 is supplied with air by an air pump 3, and the drying chamber 2 includes a drying channel 4, the upper end of which is open, and the The side walls of the drying passage 4 are evenly distributed with air jet holes, which are used to eject airflow on the one hand, and on the other hand, the air jet holes can guide the airflow so that the airflow blows to the casing at a reasonable angle to improve the casing casing. drying efficiency.

[0028] Such as figure 1 , figure 2 , image 3 , the air injection hole communicates with the air heating chamber 1, the air heated by the air heating chamber 1 is blown to the drying passage 4 through the air injection hole, and the air heating chamber 1 is provided with a heating air heating chamber 1 The heating tube can be a tubular structure with heating function such as an electric hea...

Embodiment 2

[0033] This embodiment introduces the structure of the transport frame 7 in combination with Embodiment 1.

[0034] Such as figure 1 , image 3 , the conveying frame 7 includes a frame body 10, the rotary mechanism 8 is fixed on the frame body 10, the rotary mechanism 8 includes a timing belt 11 that rotates on the frame body 10, and the hook 9 is fixed on On the synchronous belt 11, and one side of the synchronous belt 11 is located in the drying channel 4, the rotary mechanism 8 also includes a driving pulley 12 and a driven pulley 13 matched with the synchronous belt 11, The driving pulley 12 is driven to rotate by the motor 14, the driving pulley 12 and the driven pulley 13 are both rotatably connected to the frame body 10, and the slewing mechanism 8 also includes a The auxiliary wheel 15 on the top, the auxiliary wheel 15 cooperates with the synchronous belt 11. The effect of the auxiliary wheel 15 is to make the synchronous belt 11 have a reasonable movement track, s...

Embodiment 3

[0038] This embodiment introduces the fixing method of the hook 9 and the timing belt 11 .

[0039] The hook 9 is fixed on the timing belt 11 by screws.

[0040] Alternatively, the hook 9 is bonded to the timing belt 11 .

[0041] Alternatively, the hook 9 is hooked on the timing belt 11 .

[0042] The hook 9 can be fixed on the synchronous belt 11 by any method, and the specific fixing method can be freely selected by those skilled in the art, and is not limited here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com