Manufacturing process for offshore wind power foundation steel pipe pile

A manufacturing process and offshore wind power technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of large load on the upper fan, low compressibility and deep bearing layer, and cannot be directly used as the bearing layer to meet the requirements Corrosion resistance requirements, the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

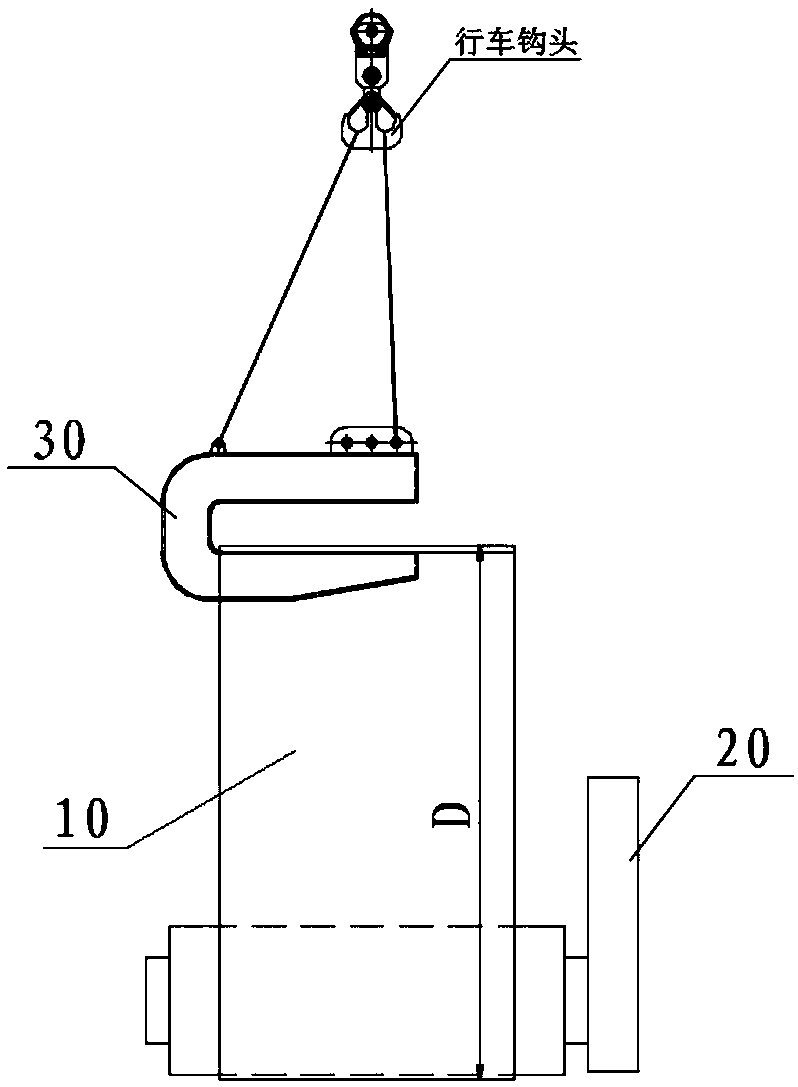

[0057] The present invention will be further described below in conjunction with accompanying drawing.

[0058] see Figure 1 to Figure 8 , the manufacturing process of the offshore wind power foundation steel pipe pile of the present invention, the steel pipe pile is formed by splicing multiple pipe joints, the upper pipe joint of the steel pipe pile is a conical cylinder, and the lower pipe joint is a straight cylinder.

[0059] The manufacturing process of the steel pipe pile of the present invention includes the following steps: pipe joint blanking, pipe joint bevel processing, pipe joint roll forming, cylinder completion inspection, pile top flange assembly, pipe joint splicing and anti-corrosion coating painting.

[0060] When performing the pipe joint bevel processing steps, it includes circular seam groove processing and longitudinal seam groove processing. 3δ, δ is the thickness of the steel plate. When the longitudinal seam is welded after rolling, the X-shaped gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com