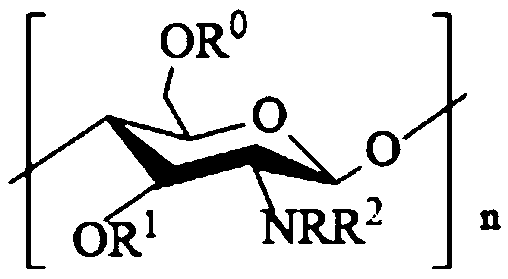

Modified crude oil demulsifier and preparation method thereof

A demulsifier and modification technology, which is applied in dehydration/demulsification by chemical methods, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problems of poor environmental friendliness and secondary pollution of demulsifiers, and achieve strong competitive adsorption capacity, oil-water Neat interface and effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

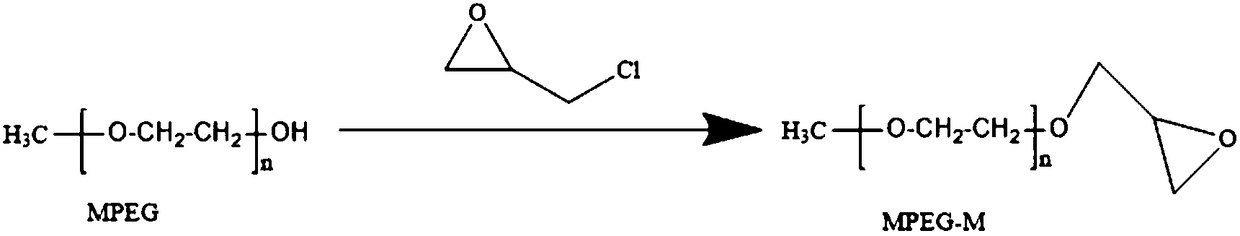

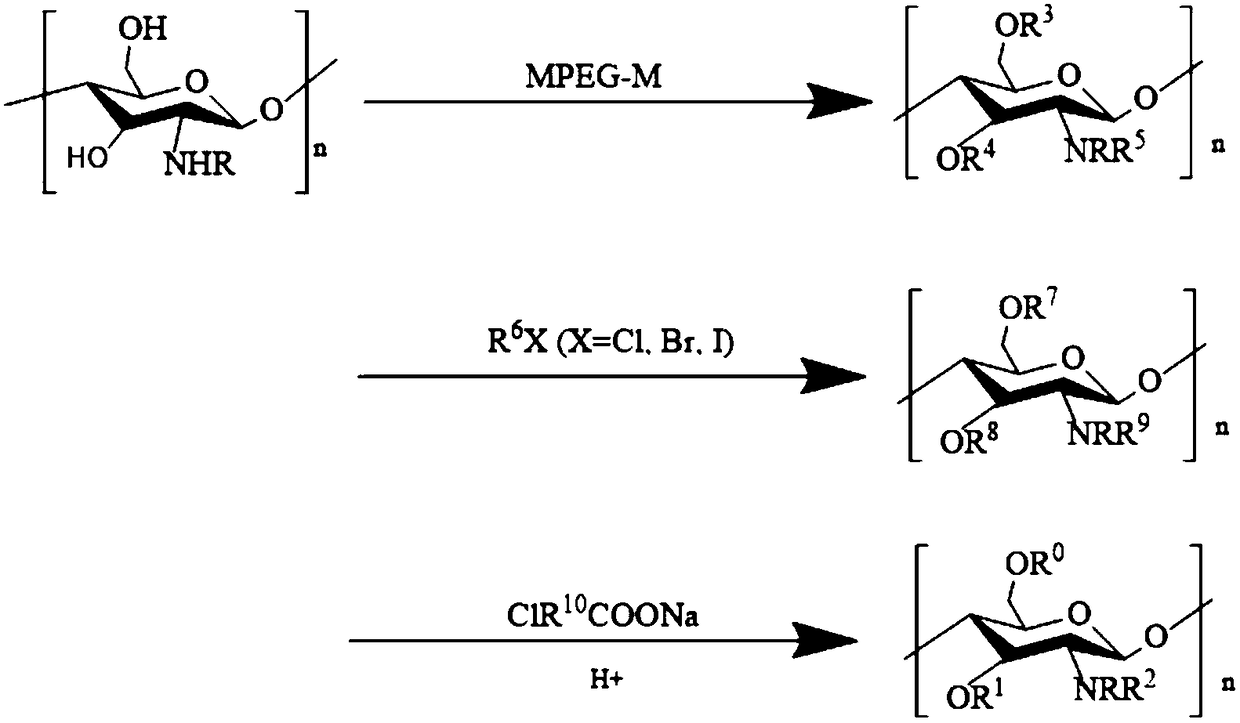

[0054] The preparation of the butyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0055] (1) Synthesis of epoxidized polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =5000) 5g (1mmol) was dissolved in 50mL of anhydrous toluene, then 50mL of tetrahydrofuran and 0.036g (1.5mmol) of sodium hydride reagent were added, the temperature was raised to 25°C, and the reaction was carried out for 4h. Slowly add 0.37mL (4mmol) epichlorohydrin dropwise into the reaction solution at a temperature of 40°C and react for 6h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and the filtrate was filtered with suction Distilled under reduced pressure and freeze-dried to obtain epoxi...

Embodiment 2

[0060] The preparation of the hexyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0061] (1) Synthesis of epoxidized polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =1900) 1.9g (1mmol) was dissolved in 50mL of anhydrous toluene, then 50mL of tetrahydrofuran and 0.036g (1.5mmol) of sodium hydride reagent were added, the temperature was raised to 25°C, and the reaction was carried out for 4h. Slowly add 0.37mL (4mmol) epichlorohydrin dropwise into the reaction solution at a temperature of 40°C and react for 6h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and the filtrate was filtered with suction Distilled under reduced pressure and freeze-dried to obtain epo...

Embodiment 3

[0066] The preparation of the octyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0067] (1) Synthesis of epoxidized polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =750) 0.75 g (1 mmol) was dissolved in 50 mL of anhydrous toluene, then 50 mL of tetrahydrofuran and 0.036 g (1.5 mmol) of sodium hydride reagent were added, the temperature was raised to 25° C., and the reaction was carried out for 4 h. Slowly add 0.37mL (4mmol) epichlorohydrin dropwise into the reaction solution at a temperature of 40°C and react for 6h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and filtered with suction Distilled under reduced pressure and freeze-dried to obtain epoxidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com