Intelligent power distribution box

A distribution box, intelligent technology, applied in the direction of coatings, anti-corrosion coatings, paints containing biocide, etc., can solve the problems of poor high temperature resistance and corrosion resistance, and achieve improved wear resistance and strong adhesion , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

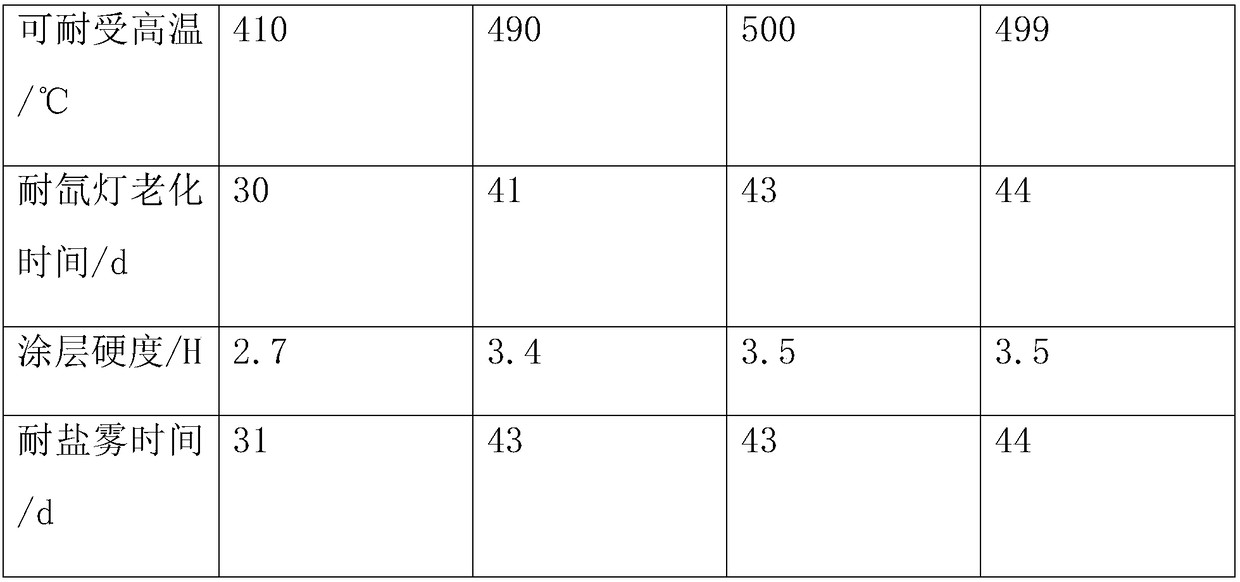

Examples

Embodiment 1

[0021] An intelligent distribution box, including a casing, the surface of the casing is coated with a protective paint, the chemical content and mass percentage of the protective paint are as follows: MA-2 thermosetting acrylic resin: 16% to 18%, polyether sulfone ketone: 5% to 7% %, nitrile rubber: 3% to 4%, phosphate: 0.6% to 0.7%, dispersant: 0.5% to 0.9%, plasticizer: 1.1% to 1.4%, silicate: 0.5% to 0.8%, Accelerator ND-42: 2.6% to 2.9%, the balance is fillers and additives.

[0022] The chemical content and mass percentage of the protective coating in this embodiment are selected as follows: MA-2 thermosetting acrylic resin: 16%, polyether sulfone ketone: 5%, nitrile rubber: 3%, phosphate: 0.6%, dispersant: 0.5% , Plasticizer: 1.1%, Silicate: 0.5%, Accelerator ND-42: 2.6%, and the balance is fillers and additives.

[0023] Wherein, the filler is a mixture of hollow ceramic microspheres and micaceous iron oxide, and the additives include organosilicon coupling agent KH55...

Embodiment 2

[0031] An intelligent distribution box, including a casing, the surface of the casing is coated with a protective coating, the chemical content and mass percentage of the protective coating are as follows: MA-2 thermosetting acrylic resin: 18%, polyether sulfone ketone: 7%, nitrile rubber: 4%, Phosphate: 0.7%, Dispersant: 0.9%, Plasticizer: 1.4%, Silicate: 0.8%, Accelerator ND-42: 2.9%, and the balance is filler and auxiliary agent.

[0032] Wherein, the filler is a mixture of hollow ceramic microspheres and micaceous iron oxide, and the additives include organosilicon coupling agent KH550 and titanate coupling agent, and the ratio between the organosilicon coupling agent KH550 and titanate coupling agent is It is 2:3.

[0033] The plasticizer is dibutyl phthalate, and the dispersant is sodium hexametaphosphate.

[0034] The preparation method of protective coating comprises the following steps:

[0035] a. Add the accelerator ND-42 and silicate into the high-speed mixer, st...

Embodiment 3

[0040] An intelligent distribution box, including a casing, the surface of the casing is coated with a protective paint, the chemical content and mass percentage of the protective paint are as follows: MA-2 thermosetting acrylic resin: 17%, polyether sulfone ketone: 6%, nitrile rubber: 3.5%, phosphate: 0.65%, dispersant: 0.7%, plasticizer: 1.25%, silicate: 0.65%, accelerator ND-42: 2.75%, and the balance is filler and auxiliary agent.

[0041] Wherein, the filler is a mixture of hollow ceramic microspheres and micaceous iron oxide, and the additives include organosilicon coupling agent KH550 and titanate coupling agent, and the ratio between the organosilicon coupling agent KH550 and titanate coupling agent is It is 2:3.

[0042] The plasticizer is dibutyl phthalate, and the dispersant is sodium hexametaphosphate.

[0043] The preparation method of protective coating comprises the following steps:

[0044] a. Add the accelerator ND-42 and silicate into the high-speed mixer, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com