Preparation method of multielement alcohol amine

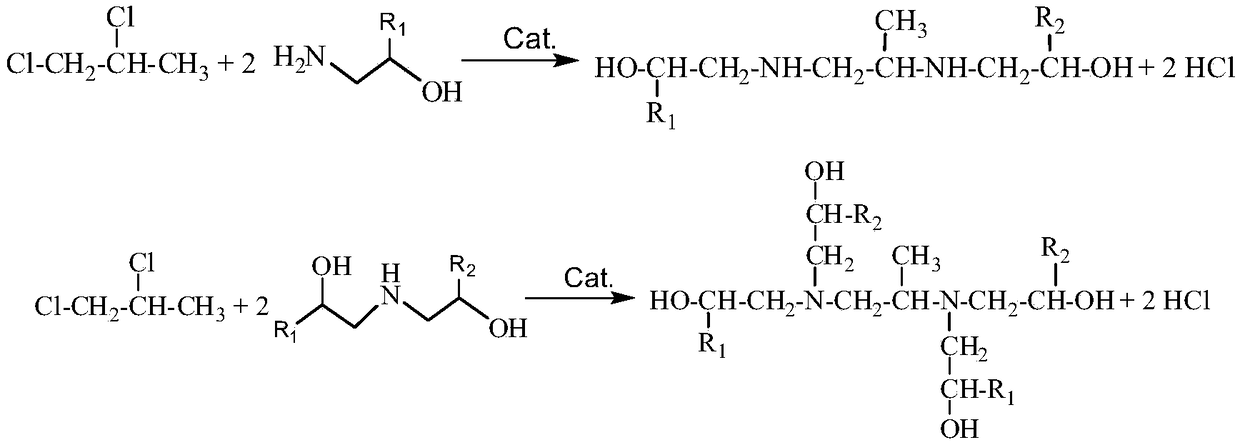

A polyol amine and alcohol amine technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of amino hydroxyl compounds, etc., can solve the problems of high ammoniation reaction pressure, waste water pollution, low product yield, etc., to achieve The effect of low operating cost, high product yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of polyol amine, comprises the steps:

[0028] Step 1: Catalyst Preparation

[0029] Roast coconut shell charcoal in a nitrogen atmosphere at 250-350°C for 3-6 hours, after cooling, soak it in 1-10mol / L sodium hydroxide or potassium hydroxide aqueous solution for 1-10 hours, filter and wash with distilled water for 2-6 times, 110- After drying at 150°C for 3-12 hours, soak in 1-10mol / L nitric acid aqueous solution for 1-12 hours, then wash the filtered coconut shell charcoal with distilled water for 2-6 times, and dry at 110-150°C for 3-12 hours for later use.

[0030] Mix the pretreated granular coconut shell charcoal with sodium hydroxide or potassium hydroxide and lanthanum nitrate or cesium nitrate evenly, place in a horse boiling furnace, and roast at 250-550°C for 6-12 hours in a nitrogen atmosphere, so that sodium hydroxide, hydroxide Potassium, lanthanum nitrate, and cesium nitrate melt and infiltrate into the gap between the activa...

Embodiment 1

[0035] Coconut shell charcoal was roasted at 300°C in a nitrogen atmosphere for 6h, cooled and soaked in 7mol / L sodium hydroxide aqueous solution for 6h, filtered and washed with distilled water for 4 times, dried at 120°C for 6h, then soaked in 7mol / L nitric acid aqueous solution for 8h, The coconut shell charcoal was washed with distilled water for 3 times, dried at 120°C for 6 hours after filtration, and roasted at 300°C for 6 hours for later use.

[0036] The processed granular coconut shell charcoal, sodium hydroxide and lanthanum nitrate are mixed according to the mass ratio of 100:5:1, and sodium hydroxide and lanthanum nitrate are prepared into a mixed solution. The coconut shell charcoal is excessively impregnated and adsorbed for 10 hours under stirring, and dried at 120°C for 8 hours. Then put it in a horse boiling furnace and roast at 350°C for 8 hours in a nitrogen atmosphere, so that sodium hydroxide and lanthanum nitrate melt and penetrate into the gap between th...

Embodiment 2

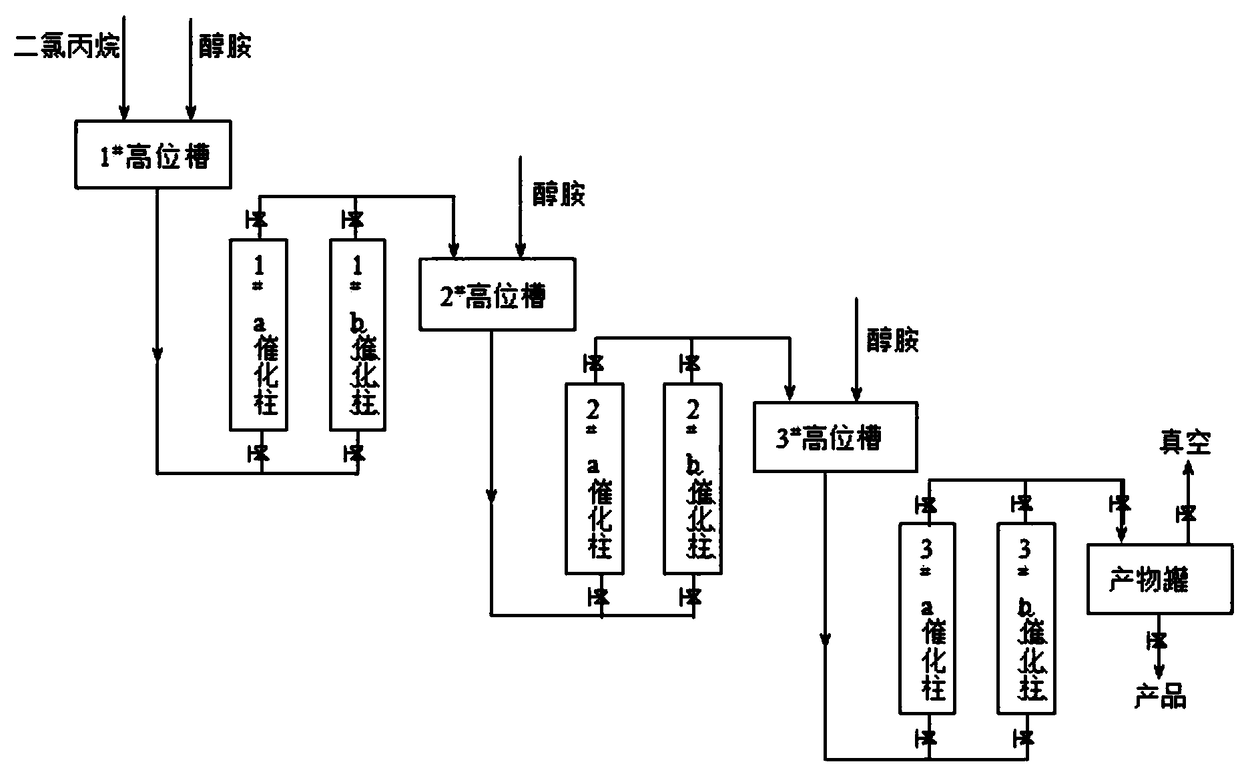

[0038] at 1 # In the head tank, alcohol amine and dichloropropane are mixed in a molar ratio of 1:1 to form a homogeneous solution, and under the action of gravity, the flow rate is adjusted to 1000mL / min, from 1 # The bottom of the catalytic column enters 1 # Catalytic column, control the column temperature at 60°C for reaction; the reaction system leaves the top of the catalytic column for 1 # column entry 2 # high slot; in 2 # high slot, from 1 # The material of the column is fully mixed with the alcohol amine metered in (alcohol amine and the original dichloropropane molar ratio is 1:2), and under the action of gravity, the mixed solution changes from 2 # The bottom of the catalytic column enters 2 # The catalytic column completes the catalytic reaction at 70°C, and the reaction material leaves the reaction column from the top of the catalytic column and enters the 3 # High slot. in 3 # The alcohol amine (alcohol amine and original dichloropropane mol ratio is 1:2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com