A method for selective hydrogenation of alkyne-containing carbon tetrafraction

A technology for selective hydrogenation and carbon four fractions, applied in the fields of hydrocarbons, chemical instruments and methods, hydrogenation to hydrocarbons, etc. Avoid bad factors and improve the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

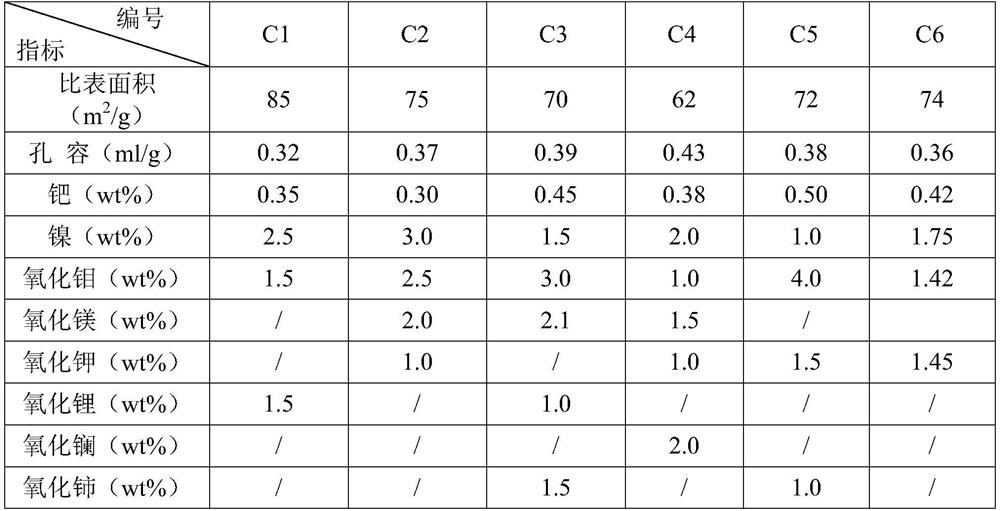

[0054] The preparation of catalysts 1-6 for the examples

[0055] Preparation of catalyst C1:

[0056] The concentration of 4L is 50g Al 2 O 3 The sodium metaaluminate solution of / L is placed in a stainless steel container with a stirrer and the bottom of the tank can pass gas, the nickel nitrate solution is prepared and put into the container at a high position, and the mixed gas of carbon dioxide and air is introduced, and the peristaltic pump is started at the same time. Control the flow rate and add the prepared nickel nitrate solution dropwise, the carbon dioxide concentration in the mixed gas is 70v%, and the flow rate is 4Nm 3 / h, the reaction temperature was 40°C, the pH value of the reaction end was 10, carbon dioxide was stopped, aged for 30 minutes, the mother liquor was separated by filtration, washed, and dried at 120°C for 5 hours to obtain nickel-containing pseudoboehmite.

[0057] The nickel-containing pseudo-boehmite was mixed and kneaded with nitric acid ...

Embodiment 1

[0084] The alkyne-rich C4 fraction is diluted with raffinate C4, and the weight ratio of the alkyne-rich C4 fraction to the raffinate C4 is 1:1. The isothermal reactor adopts a single-stage isothermal bubbling bed, and uses catalyst C1, which is reduced at 120 °C for 6 hours under a hydrogen atmosphere. The reaction inlet temperature is 50℃, the reaction pressure is 1.5MPa, and the liquid space velocity is 7h -1 , the molar ratio of hydrogen to alkyne is 3.5, and Table 2 shows the composition of materials before and after the reaction.

[0085] Table 2 Material composition before and after the reaction

[0086]

Embodiment 2

[0088] The alkyne-rich C4 fraction is diluted with raffinate C4 and cracked C4, and the weight ratio of the alkyne-rich C4 fraction to (raffinate C4+cracked C4) is 1:6. The isothermal reactor adopts a single-stage isothermal bubbling bed, and uses catalyst C2, which is reduced at 120 °C for 6 hours under a hydrogen atmosphere. The reaction inlet temperature is 60℃, the reaction pressure is 2.0MPa, and the liquid space velocity is 12h -1 , the molar ratio of hydrogen to alkyne is 2.5, and Table 3 shows the composition of materials before and after the reaction.

[0089] Table 3 Material composition before and after the reaction

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com