High-quality organic fertilizer prepared by mushroom base material and preparation method of high-quality organic fertilizer

An organic fertilizer, high-quality technology, applied in the direction of organic fertilizer, inorganic fertilizer, fertilizer made of biological waste, etc., can solve the problem that the effect of organic fertilizer is not very good, and achieve better effect, uniform surface and rich nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

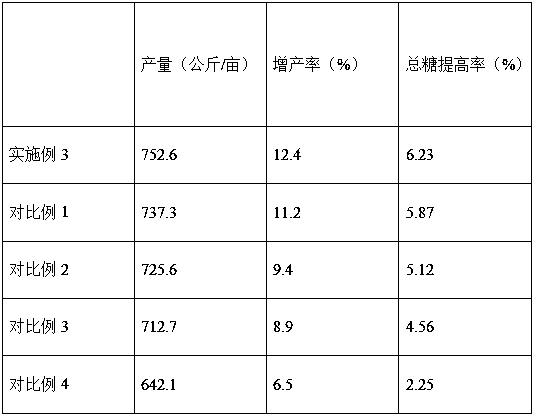

Examples

Embodiment 1

[0026] The production of high-quality organic fertilizer utilizing the mushroom base material of the present embodiment comprises the following raw materials in parts by weight:

[0027] 52 parts of mushroom base material, 18 parts of soybean meal, 14 parts of animal manure, 16 parts of pretreated attapulgite, 12 parts of rice husk ash, 3 parts of mudstone, 4 parts of forsterite, 3 parts of phosphate phosphate, 2 parts of sodium alginate, 12 parts of deionized water.

[0028] As a further solution of the present invention: the preparation method of the mushroom base material is to mix mushrooms and straws in a weight ratio of 3:1, then dry them in the sun, then pulverize them, then perform steam explosion treatment, and then perform ultraviolet irradiation treatment , then add EM bacteria activation solution, send it into the protective film for fermentation, the fermentation temperature is 63°C, and ferment for 6 days. After the fermentation is completed, adjust the pH to 5.5...

Embodiment 2

[0039] The production of high-quality organic fertilizer utilizing the mushroom base material of the present embodiment comprises the following raw materials in parts by weight:

[0040] 58 parts of mushroom base material, 22 parts of soybean meal, 18 parts of animal manure, 22 parts of pretreated attapulgite, 14 parts of rice husk ash, 6 parts of mudstone, 8 parts of forsterite, 6 parts of phosphate phosphate, 5 parts of sodium alginate, 14 parts of deionized water.

[0041]As a further solution of the present invention: the preparation method of the mushroom base material is to mix mushrooms and straws in a weight ratio of 3:1, then dry them in the sun, then pulverize them, then perform steam explosion treatment, and then perform ultraviolet irradiation treatment , then add EM bacteria activation solution, send it into the protective film for fermentation, the fermentation temperature is 65°C, and ferment for 8 days. After the fermentation is over, adjust the pH to 6.5 with ...

Embodiment 3

[0052] The production of high-quality organic fertilizer utilizing the mushroom base material of the present embodiment comprises the following raw materials in parts by weight:

[0053] 55 parts of mushroom base material, 20 parts of soybean meal, 16 parts of animal manure, 19 parts of pretreated attapulgite, 13 parts of rice husk ash, 4.5 parts of mudstone, 6 parts of forsterite, 4.5 parts of phosphate phosphate, 3.5 parts of sodium alginate, 13 parts of deionized water.

[0054] As a further solution of the present invention: the preparation method of the mushroom base material is to mix mushrooms and straws in a weight ratio of 3:1, then dry them in the sun, then pulverize them, then perform steam explosion treatment, and then perform ultraviolet irradiation treatment , then add EM bacteria activation solution, send it into the protective film for fermentation, the fermentation temperature is 64°C, and ferment for 7 days. After the fermentation is completed, adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com