Nanocomposite catalysts with high metal loading and dispersion and their preparation and application

A nanocomposite and catalyst technology, applied in nanotechnology for materials and surface science, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of metal utilization efficiency reduction, mass transfer Problems such as deterioration of properties, to achieve the effect of high utilization, narrow size distribution, and uniform distribution of alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

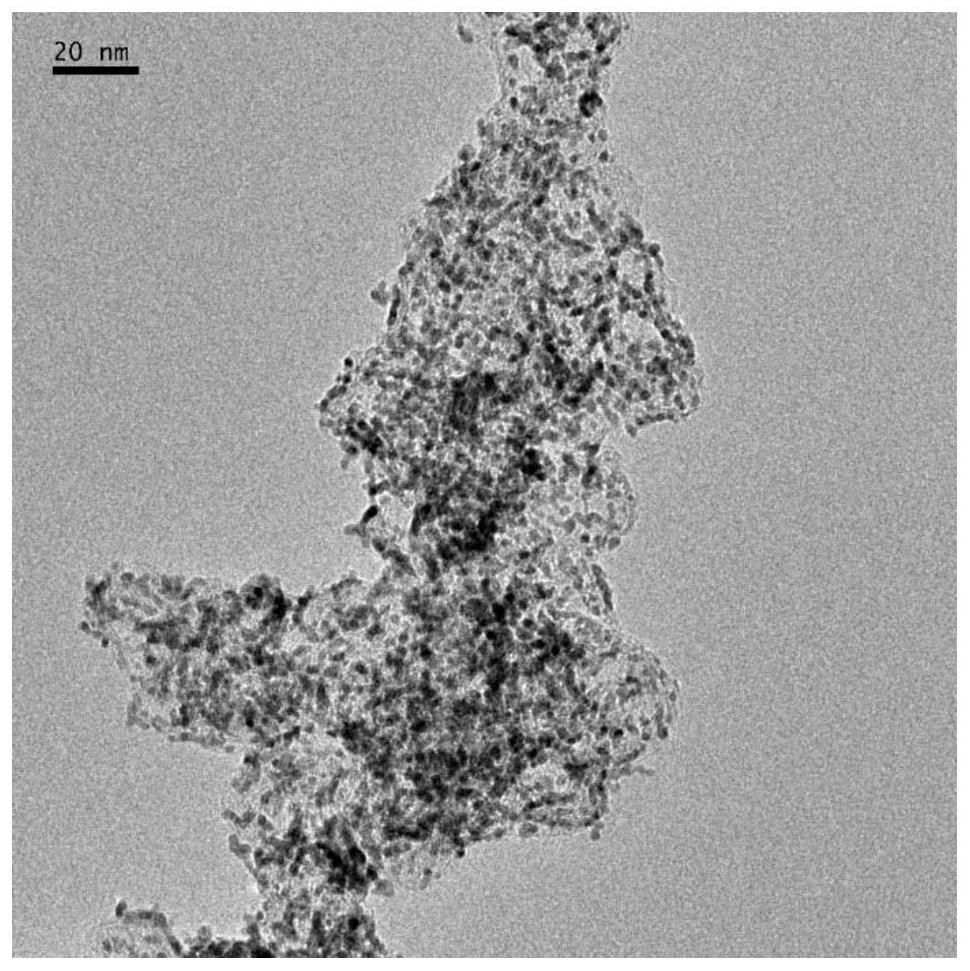

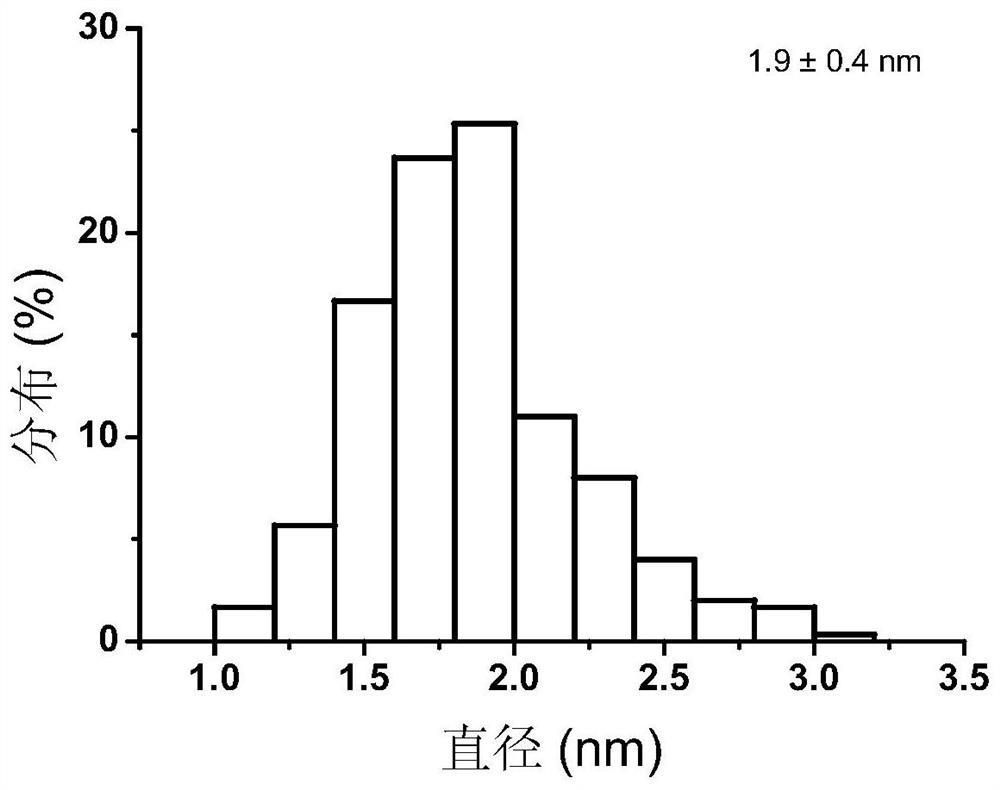

[0057] Example 1, Synthesis and performance of a nanocomposite catalyst (Pt content: 63wt%) composed of organic amine salt modified carbon support and Pt metal nanoclusters

[0058] 1) Add 1g H 2 PtCl 6 ·6H 2 O was dissolved in 50 mL of ethylene glycol, and the resulting solution was mixed with 50 mL of NaOH in ethylene glycol (0.26 mol / L). at N 2 The mixture was stirred under atmosphere and heated to 160 °C by microwave for 5 min, under N 2 Cool to room temperature under the atmosphere to prepare a Pt metal nanocluster colloidal solution with a Pt concentration of 3.7 g / L;

[0059] 2) Dissolve 0.2764 g of trimethylhexadecyl ammonium bromide (CTAB) in 20 mL of chloroform. Add 18.5 mg of carbon powder (EC-600JD) to the above mixture and ultrasonically treat it for 5 minutes. The solid in the mixture is separated by centrifugation (4000rpm, 5min) and washed with chloroform. The solid obtained by centrifugation is redispersed in 20mL chloroform;

[0060] 3) 20 mL of the Pt...

Embodiment 2

[0075] Example 2, Synthesis and performance of nanocomposite catalyst (Pt content: 73wt%) composed of organic amine salt modified carbon support and Pt metal nanoclusters

[0076] 1) prepare the Pt metal nanocluster colloidal solution of 3.7g / L by the method for embodiment 1;

[0077] 2) Add 0.6911g of trimethylhexadecylammonium bromide (CTAB) into 50mL of chloroform, and sonicate the resulting mixture for 5 minutes; add 18.5mg of carbon powder (EC-600JD) to the above mixture and sonicate for 1.5 hours , add 50mL of the Pt metal nanocluster colloidal solution prepared in the first step, and stir the resulting mixture in a water bath (12000rpm, 2 hours); filter and separate the solid in the mixture, wash the solid with hot water (80-100°C) and remove it Drying in a vacuum drying oven at 60° C., the nanocomposite catalyst C composed of the organic amine salt modified carbon support and Pt metal nanoclusters is obtained.

[0078] The ICP-AES test shows that the mass percentage o...

Embodiment 3

[0079] Example 3, Synthesis and performance of nanocomposite catalyst (Pt content: 65wt%) composed of organic amine salt modified carbon support and Pt metal nanoclusters

[0080] Tetradecyltrimethylammonium bromide was used instead of trimethylhexadecylammonium bromide in Example 2, and synthesized according to the method described in Example 2 to obtain the nanocomposite catalyst.

[0081] ICP-AES test shows that the mass percentage of Pt metal nanoclusters in the prepared nanocomposite catalyst is 65wt%. Electrochemical catalytic experiments showed that the nanocomposite catalyst had an activity of 345A / g catalyst (0.85V vs RHE) for the oxygen reduction reaction in oxygen-saturated perchloric acid solution (0.1M) ( Figure 15 ). TEM image ( Figure 16 ) shows that the number-average particle size of metal nanoclusters in the nanocomposite catalyst is 1.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com