A flue gas purification system coupled with desulfurization, denitrification and carbon capture driven by waste heat of flue gas and flue gas treatment method

A flue gas purification system and flue gas waste heat technology, which are applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high cost and difficult utilization of industrial boiler flue gas, and reduce energy consumption and equipment cost. , The effect of improving fuel utilization efficiency and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

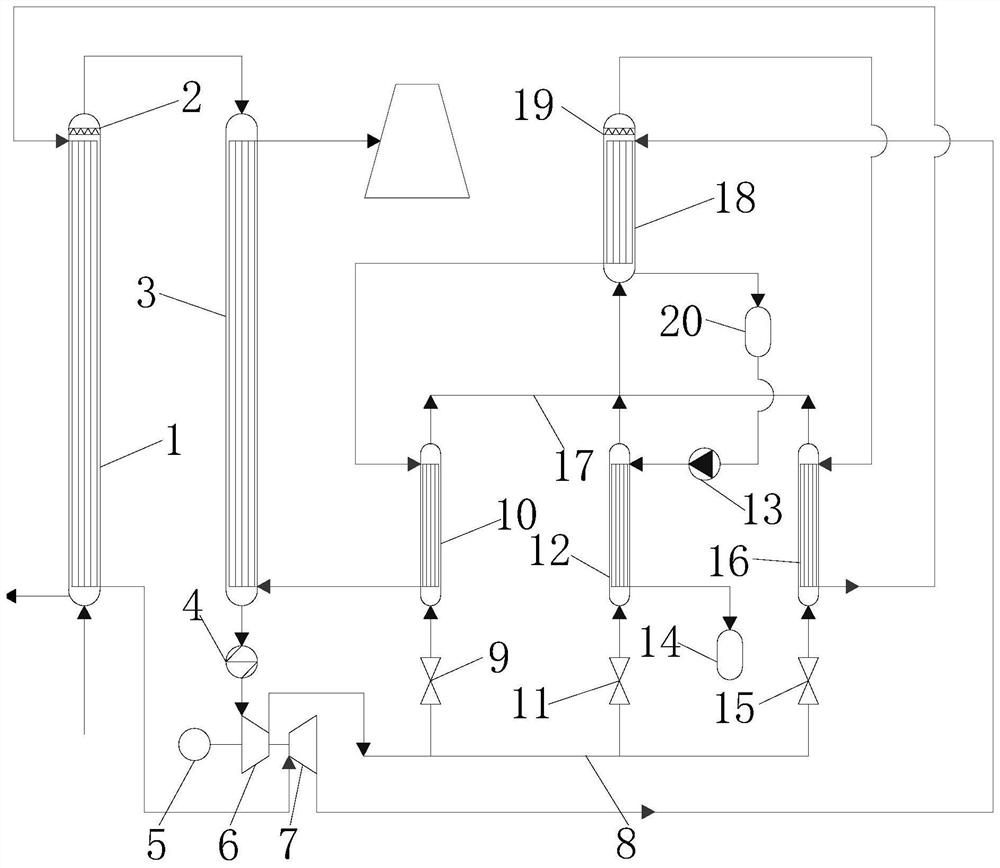

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment. In this embodiment, the flue gas purification system coupled with desulfurization, denitrification and carbon capture driven by waste heat of flue gas consists of a high-temperature flue gas heat exchange tower 1, No. 1 steam-water separator 2, a low-temperature flue gas heat exchange tower 3, Flue gas water cooler 4, multiple compressors 6, multiple expanders 7, precooler inlet pipe 8, No. 1 precooler inlet valve 9, No. 1 precooler 10, No. 2 precooler inlet Gas valve 11, No. 2 pre-cooler 12, high-pressure pump 13, No. 2 liquid storage tank 14, No. 3 pre-cooler inlet valve 15, No. 3 pre-cooler 16, pre-cooler exhaust main pipe 17, flue gas Condensing tower 18, No. 2 steam-water separator 19 and No. 1 liquid storage tank 20 constitute;

[0022] The shell-side air inlet of the high-temperature flue gas heat exchange tower 1 communicates with the boiler flue gas outlet, and a No. 1 steam-water sep...

specific Embodiment approach 2

[0029] Specific Embodiment 2: This embodiment differs from Specific Embodiment 1 in that: the high-temperature flue gas heat exchange tower 1, the No. 1 precooler 10, the No. 2 precooler 12, the No. 3 precooler 16 and the flue gas The condensation tower 18 is a partitioned wall heat exchanger. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the low-temperature flue gas heat exchange tower 3 is a regenerative heat exchanger. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com