Synthetic paper master batches with PP as carrier and preparation method thereof

A synthetic paper and masterbatch technology, which is applied in the field of synthetic paper processing, can solve the problems of weak tear resistance, inconvenient addition, poor folding performance, etc., and achieve the effects of saving costs, improving convenience, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

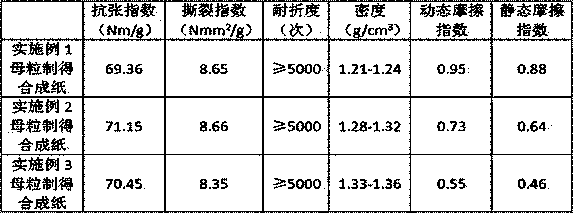

Examples

Embodiment 1

[0034] (1) Ingredients: The components of the masterbatch raw materials are sent to the intelligent feeder, and the components are accurately proportioned by the intelligent feeder according to the following parts by weight:

[0035] Phosphate-coated ground calcium carbonate with a particle size of 10-15 μm 65-70 parts by weight

[0036] Melt flow rate is 3.2-3.5g / 10min polypropylene 22-24.5 parts by weight

[0037] DLTDP of amines 0.12-0.15 parts by weight

[0038] Calcium stearate 0.28-0.3 parts by weight

[0039] Titanium dioxide 4-5 parts by weight

[0040] Allure Red 0.03-0.05 parts by weight

[0041] (2) Mixing: Send the raw materials in step (1) into the mixing chamber of the mixer, control the temperature of the mixer chamber at 70-90°C, and perform mixing by high-speed shear at 680-700r / min;

[0042] (3) Melting: shear the mixed material in the mixer cavity in step (2) at a high speed of 600~700r / min to 210~240°C to form a highly dispersed molten polymer;

[0043...

Embodiment 2

[0047] (1) Ingredients: The components of the masterbatch raw materials are sent to the intelligent feeder, and the components are accurately proportioned by the intelligent feeder according to the following parts by weight:

[0048] Particle size 10-15 μm mixed ground calcium carbonate powder 65-75 parts by weight

[0049] Melt flow rate is 3.2-3.7g / 10min polypropylene 24-26.5 parts by weight

[0050] Mono-tert-butyl-p-cresol 0.15-0.18 parts by weight

[0051] Zinc stearate 0.28-0.32 parts by weight

[0052] Titanium dioxide 3-5 parts by weight

[0053] Brilliant blue 0.02-0.03 parts by weight

[0054] Wherein, the mixed ground calcium carbonate powder is calculated by weight percentage of the mixed ground calcium carbonate powder, and the glycerol methacrylate-coated heavy calcium carbonate powder with a particle diameter of 10-15 μm accounts for 30%-35%. Stearic acid-coated ground calcium carbonate powder with a diameter of 10-15 μm accounts for 30%-35%, and uncoated calc...

Embodiment 3

[0061] (1) Ingredients: The components of the masterbatch raw materials are sent to the intelligent feeder, and the components are accurately proportioned by the intelligent feeder according to the following parts by weight:

[0062] 68-70 parts by weight of stearic acid-coated ground calcium carbonate powder with a whiteness of 98% and a particle size of 1-5 μm

[0063] The melt flow rate is 2.8-3.3g / 10min polypropylene 24-26.5 parts by weight

[0064] Hindered phenol 1010 0.12-0.16 parts by weight

[0065] Zinc stearate 0.28-0.32 parts by weight

[0066] Titanium dioxide 4.5-5 parts by weight

[0067] Ultramarine 0.02-0.03 parts by weight

[0068] (2) Mixing: Send the raw materials in step (1) into the mixing chamber of the mixer, control the temperature of the mixer chamber at 75~85°C, and perform mixing by high-speed shearing at 600~650r / min;

[0069] (3) Melting: shear the mixed material in the mixer chamber in step (2) at a high speed of 600~650r / min to 225~235°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com