A kind of waste rubber regeneration process and preparation method thereof

A technology of waste rubber and process, which is applied in the field of rubber, can solve the problems of increasing the uniformity of the rubber material and the effect of plasticizing and decoupling, reducing the activation energy of tire rubber blocks, and reducing the bond energy, so as to improve the performance of regeneration and shorten the regeneration time , The effect of improving regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 A kind of waste tread rubber regeneration process and its preparation method

[0057] Components: by weight fraction: 100 parts of waste tread rubber, 2 parts of orange peel oil, 2 parts of tributyl citrate, 3 parts of zinc dithiocarbamate, 2 parts of special effect activator 580, hexamethylene Tetramine 4 parts.

[0058] Preparation:

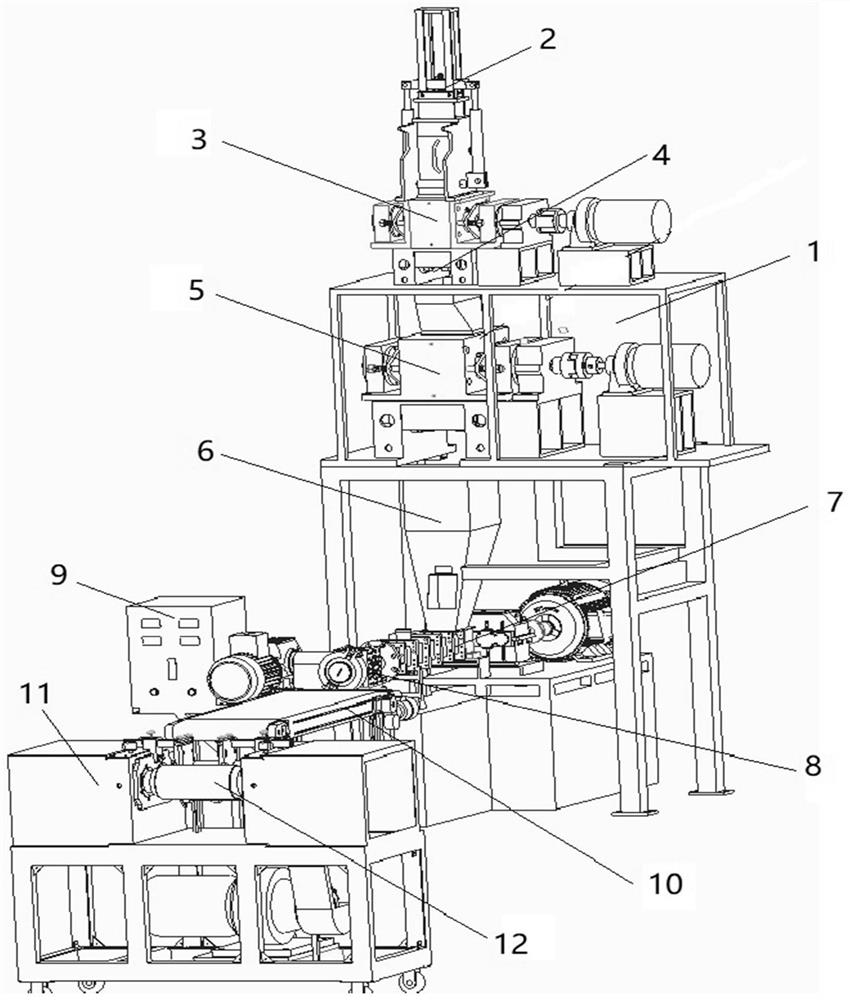

[0059] (1) After cleaning and drying the waste tread rubber first, break it into small pieces of 10mm×10mm×5mm, and then mix it with lemon peel oil, trioctyl citrate, zinc dithiocarbamate and six Methylenetetramine was weighed and put into the tandem internal mixer 1 for banburying, and the filling factor was adjusted to 0.7, the pressure of the upper top bolt was 0.5Mpa, and the rotor speed of the upstream banburying chamber 3 was set at 50r / min , the cooling water temperature is set to 65°C, press down the top bolt 2 of the tandem internal mixer and knead for 1 minute, then lift the bolt and add the component content spe...

Embodiment 2

[0065] Embodiment 2 A kind of waste tread rubber regeneration process and its preparation method

[0066] Components: by weight fraction: 100 parts of waste tread rubber, 2.2 parts of lemon peel oil, 2.2 parts of trioctyl citrate, 3.2 parts of zinc dithiocarbamate, 2.2 parts of special effect activator 580, hexamethylene Tetramine 4.2 parts.

[0067] Preparation:

[0068] (1) First, after cleaning and drying the waste tread rubber, it is broken into small pieces of 6mm×6mm×5mm, and then mixed with lemon peel oil, trioctyl citrate, zinc dithiocarbamate and six The methylenetetramine is weighed and put into the tandem internal mixer 1 for banburying, the rotor speed of the upstream internal mixing chamber 3 is set at 60r / min, and the filling factor is adjusted to 1.05, and the pressure of the top pin is 0.5Mpa , the cooling water temperature is set to 65°C, press down the top bolt 2 of the tandem internal mixer and knead for 1 minute, then lift the bolt and add the component c...

Embodiment 3

[0074] Embodiment 3 A kind of waste tread rubber regeneration process and its preparation method

[0075] Components: by weight fraction: 100 parts of waste tread rubber, 2 parts of lemon peel oil, 2 parts of trioctyl citrate, 3 parts of zinc dithiocarbamate, 2 parts of special effect activator 580, hexamethylene 4 parts of tetramine and 0.1 part of lignin.

[0076] Preparation method: same as Example 1, add lignin and special effect activator 580 together.

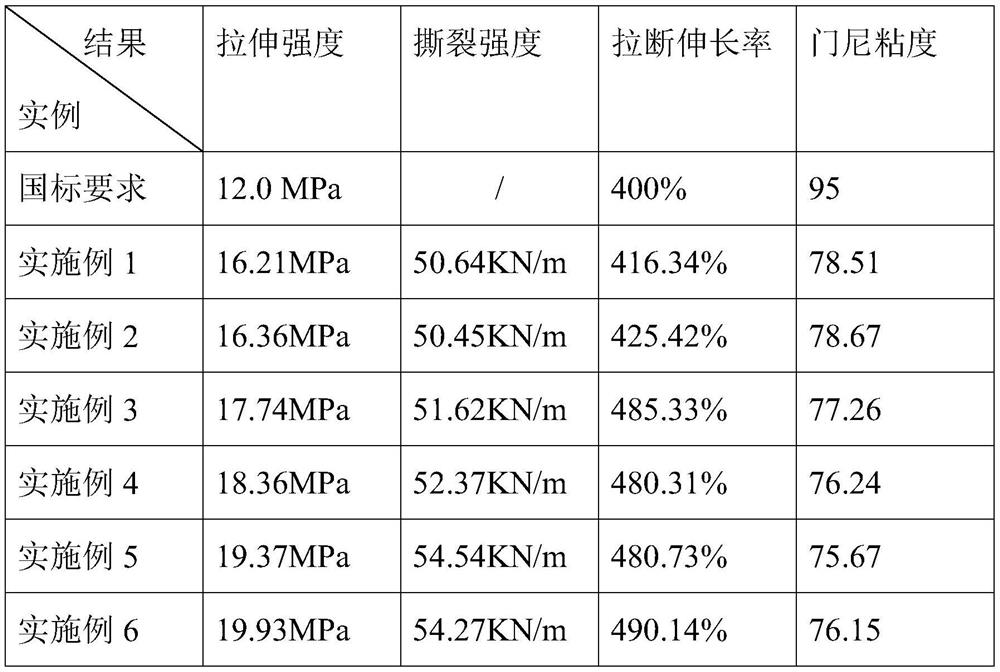

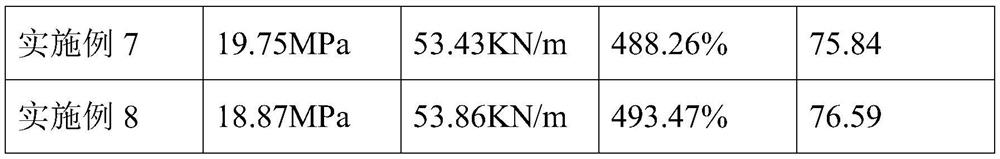

[0077] Its properties are as follows: tensile strength 17.74MPa, tear strength 51.62KN / m, elongation at break 485.33%. , Mooney viscosity 77.26.

[0078] The properties of tread recycled rubber in the national standard GB / T 13460-2016 general specification for recycled rubber: tensile strength 12.0MPa, elongation at break 400%, Mooney viscosity 95.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com