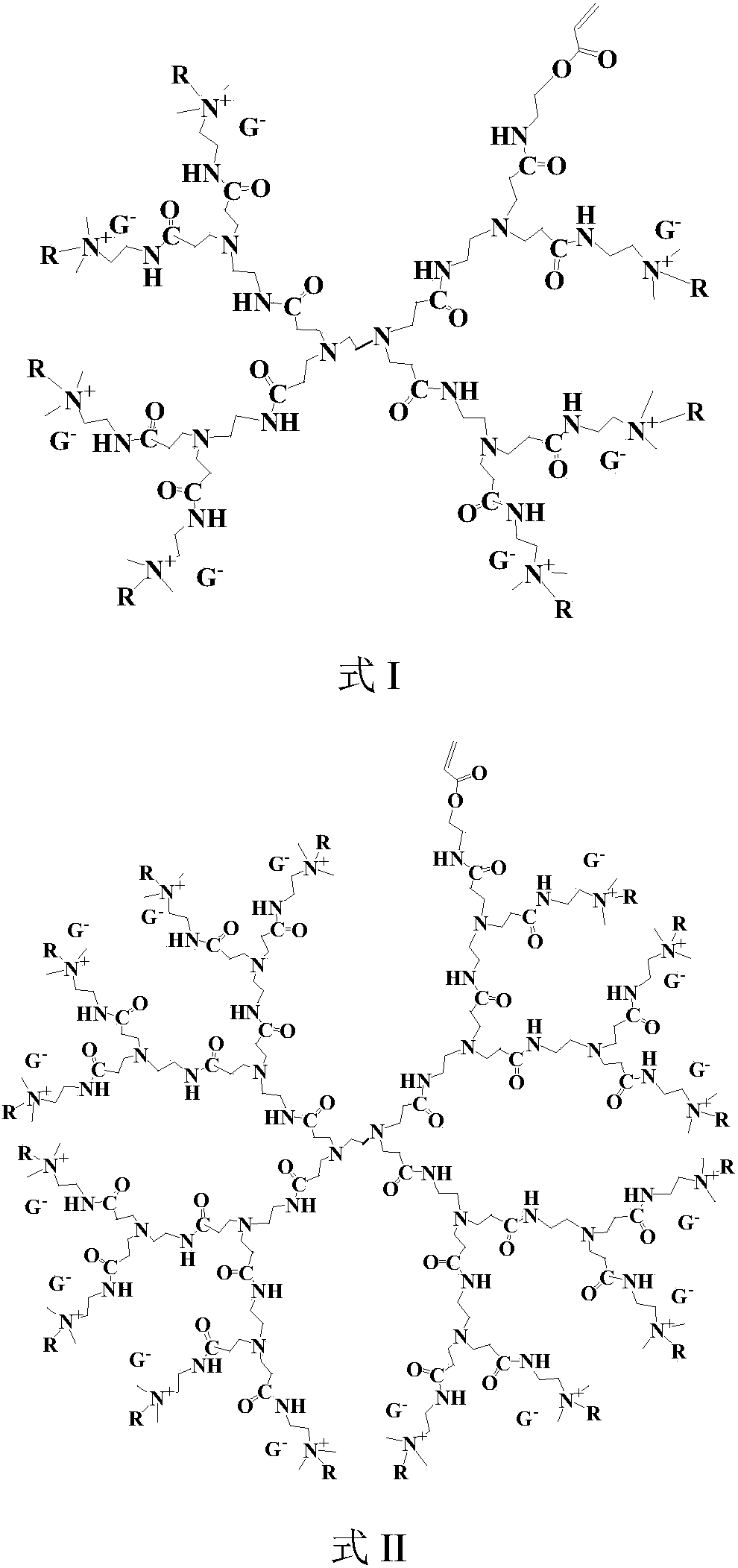

Amphipathic high-molecular viscous oil activator and application thereof

An amphiphilic polymer and activator technology, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of high exploitation cost and difficulty in developing heavy oil reservoirs, and can reduce the viscosity of heavy oil and improve the The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

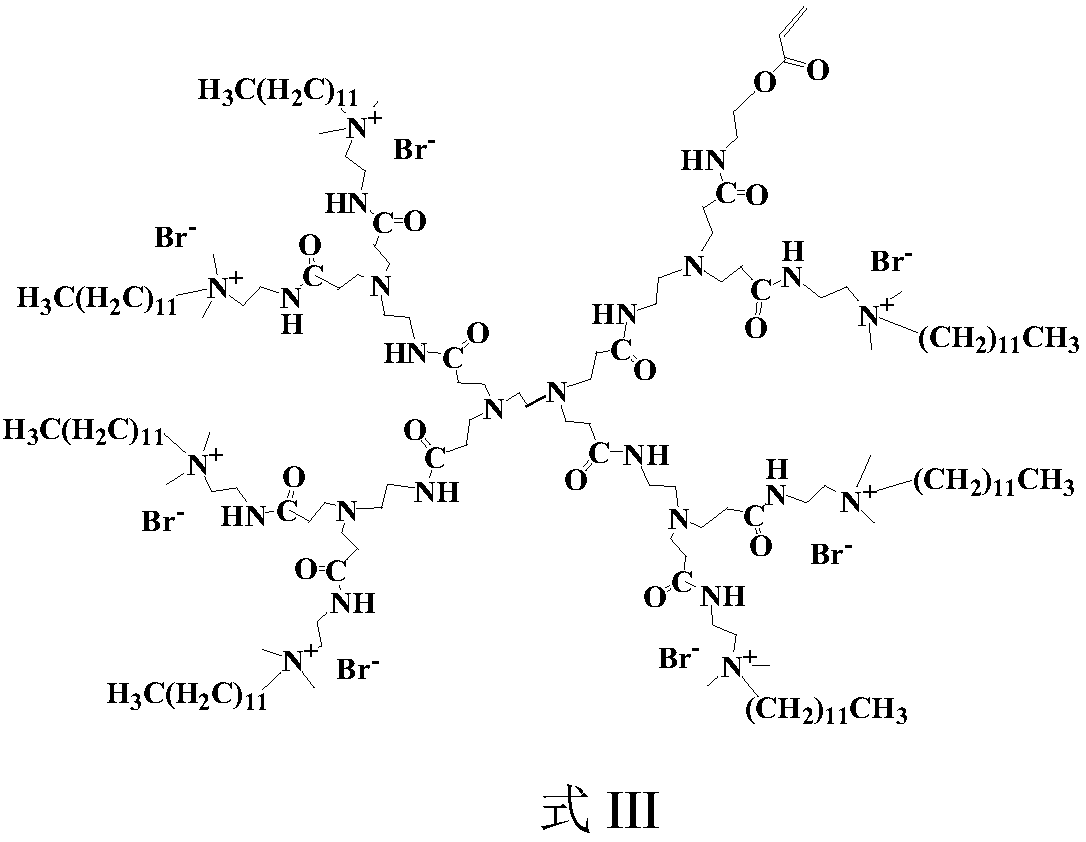

Embodiment 1

[0034] Synthesize amphiphilic polymer heavy oil activator 1 by the following method:

[0035] In the reaction system, the dendritic unsaturated functional monomer shown in comonomer acrylamide, sodium acrylate, maleic anhydride, dimethyl allyl dodecyl ammonium chloride and formula (III) accounts for the total reaction system quality The fraction is 28% by weight and the remainder is deionized water. The molar percentages of each comonomer in the total monomers are 77.5mol%, 15.5mol%, 3.7mol%, 2.8mol%, 0.5mol% in turn. Add comonomer to deionized water and stir until completely dissolved. The pH regulator sodium hydroxide was added to adjust the pH of the reaction solution to about 7.6, and then the temperature of the reaction system was lowered to 4° C., and the oxygen in the reaction system was removed by passing nitrogen gas for 60 minutes. Add the initiator azobisisobutylamidine hydrochloride (V50), ammonium persulfate and sodium bisulfite sequentially under nitrogen prote...

Embodiment 2

[0043] Synthesize amphiphilic polymer heavy oil activator 2 by following method:

[0044] In the reaction system, the dendritic unsaturated functional monomer shown in comonomer acrylamide, potassium acrylate, maleic anhydride, dimethyl allyl dodecyl ammonium chloride and formula (III) accounts for the total reaction system quality The fraction is 23 wt%, the rest is deionized water. The molar percentages of the comonomers in the total monomers are 66.5 mol%, 23.5 mol%, 5.5 mol%, 4.3 mol%, 0.2 mol% in turn. Add comonomer to deionized water and stir until completely dissolved. The pH regulator sodium carbonate was added to adjust the pH of the reaction solution to about 7.2, and then the temperature of the reaction system was lowered to 6° C., and the oxygen in the reaction system was removed by passing nitrogen gas for 60 minutes. Under nitrogen protection, the initiator azobisisobutylamidine hydrochloride (V50), sodium persulfate and sodium thiosulfate were sequentially add...

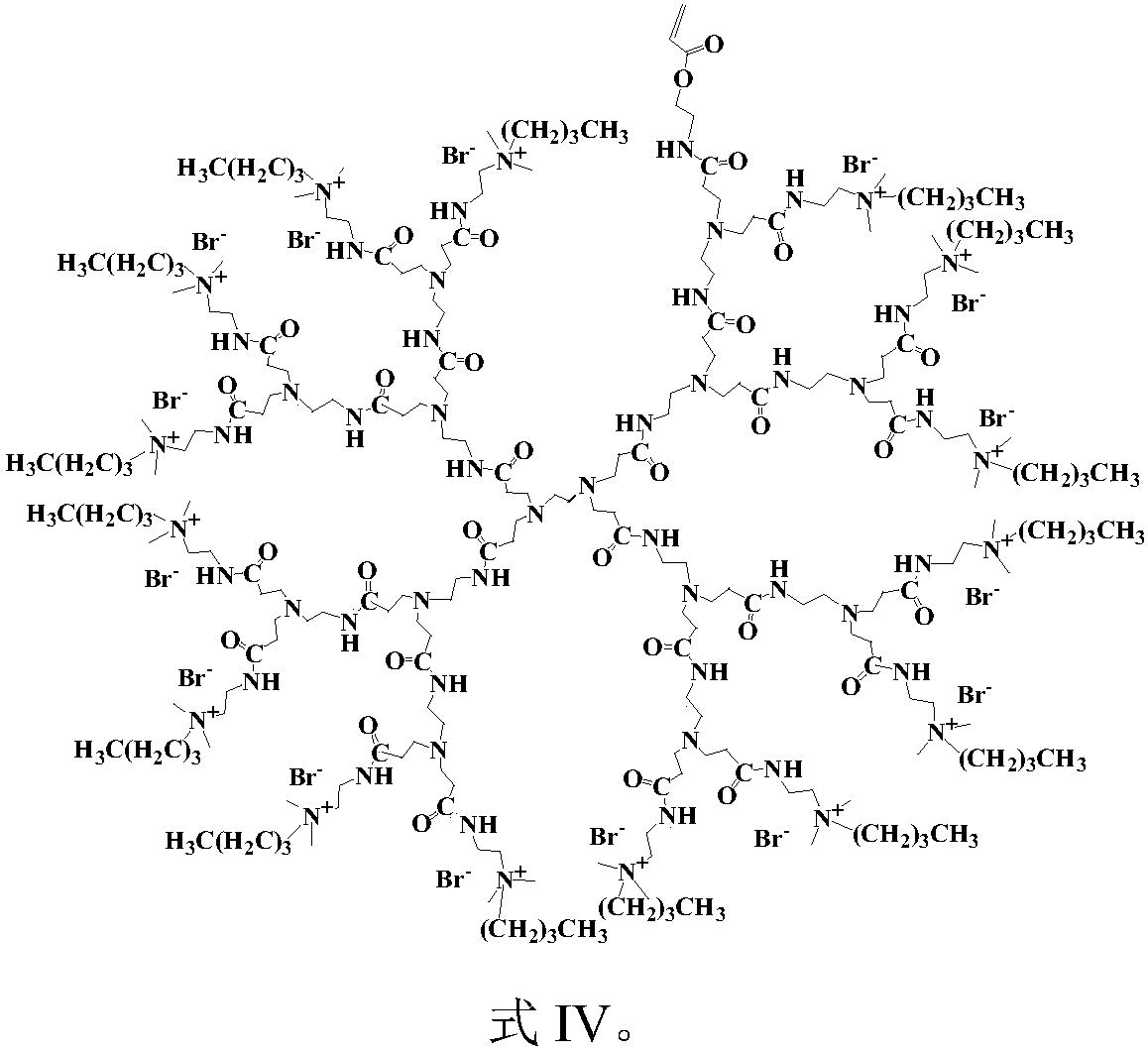

Embodiment 3

[0046] Synthesize amphiphilic polymer heavy oil activator 3 by following method:

[0047]In the reaction system, the dendritic unsaturated functional monomer shown in comonomer acrylamide, sodium acrylate, maleic anhydride, dimethyl allyl dodecyl ammonium chloride and formula (IV) accounts for the total reaction system quality The fraction is 22% by weight and the remainder is deionized water. The mole percentages of each comonomer in the total monomers are 81.5 mol%, 10.2 mol%, 4.3 mol%, 3.8 mol%, 0.2 mol% in turn. Add comonomer to deionized water and stir until completely dissolved. The pH regulator sodium hydroxide was added to adjust the pH of the reaction solution to about 8.5, and then the temperature of the reaction system was lowered to 5° C., and the oxygen in the reaction system was removed by passing nitrogen gas for 60 minutes. Under nitrogen protection, the initiator azobisisobutylamidine hydrochloride (V50), potassium persulfate and sodium thiosulfate were sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com