Welding method of aluminum alloy plate

A welding method and technology for aluminum alloy plates, applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve problems such as affecting the mechanical properties of the welding area, eliminate the heat-engine affected area, increase the effective welding area, The effect of improving the strength of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

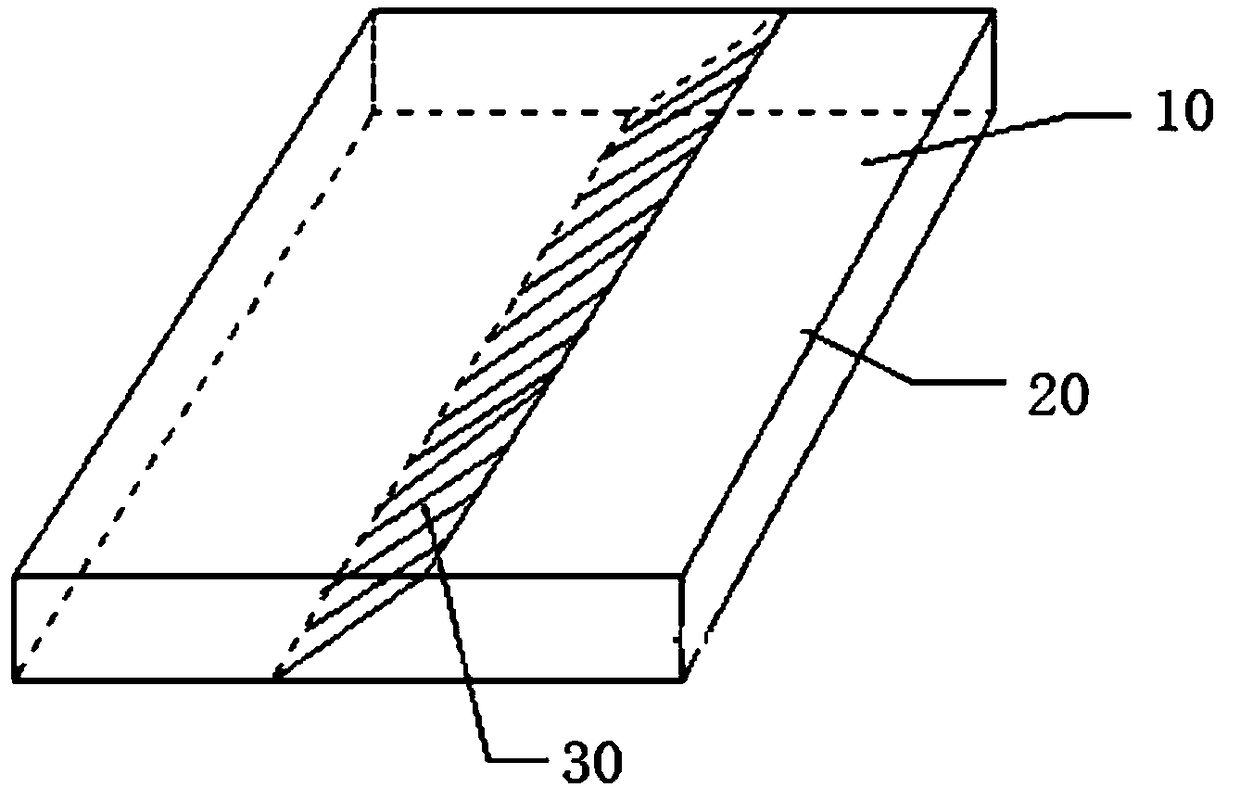

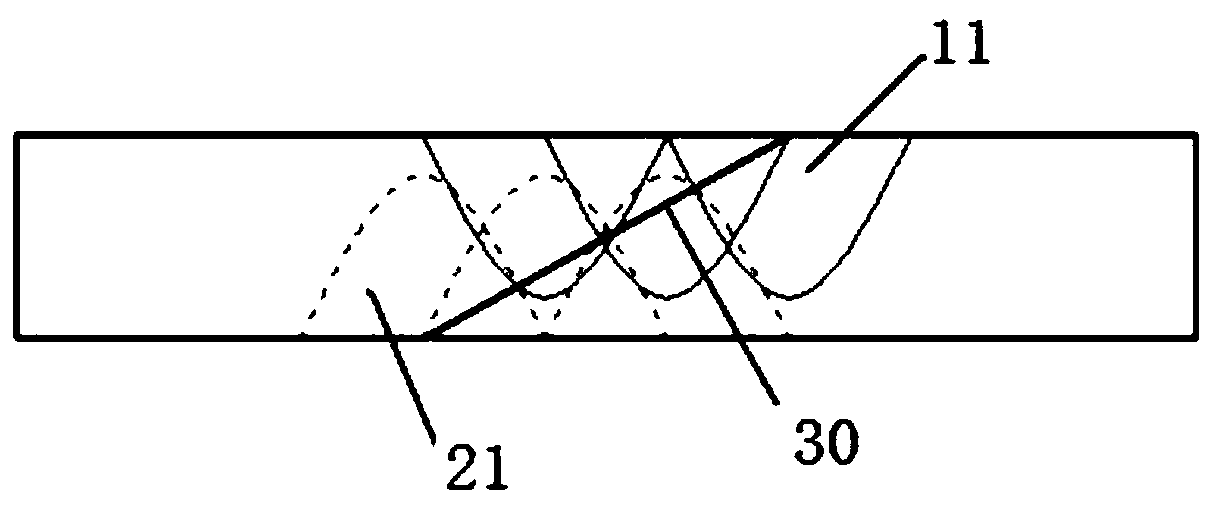

Embodiment 1

[0029] The specifications of 7075 aluminum alloy extruded plate are: length × width × thickness = 170mm × 90mm × 8mm. The edge joints of the two extruded plates to be welded are pre-processed into an inclined joint section 30, and the inclined angle is 30° from the horizontal plane. After cleaning and polishing, they are docked and fixed on the clamping device. Use a special mixing head to make blind holes on the welding surface. The diameter of the blind holes is 2mm, the depth is 4mm, and the interval is 4mm. The ball-milled uniform Al, Sc, Zr mixed powder is filled and compacted and then sealed. The upper and lower surfaces 10, 20 are the same operation. The mixed powder ratio is Al-0.2Sc-0.1Zr (mass ratio). The model SXT-10 gantry mobile friction stir welding machine is used for double-sided friction stir welding. The specifications and process parameters of the stirring needle are as follows: the length of the stirring needle: 5mm, the pressing amount of the shoulder: 1mm...

Embodiment 2

[0031] The specifications of 7075 aluminum alloy extruded plate are: length × width × thickness = 170mm × 90mm × 8mm. After the surfaces of the two extruded plates to be welded are cleaned and polished, they are docked and fixed on the clamping device. Use a special stirring head to make blind holes on the welding surface. The diameter of the blind holes is 2mm, the depth is 4mm, and the interval is 4mm. The ball-milled uniform Al, Sc, Zr mixed powder is filled and compacted, and the groove is sealed. The mixed powder ratio is Al-0.2Sc- 0.1Zr (mass ratio). The model SXT-10 gantry mobile friction stir welding machine is used for single-sided friction stir welding. The specifications and process parameters of the stirring pin are as follows: the length of the stirring pin: 5mm, the pressing amount of the shoulder: 1mm, the inclination angle of the stirring head: 2° , Welding speed: 90mm / min, rotation speed: 1200r / min. Place stamping liquid nitrogen cooling step by step behind ...

Embodiment 3

[0033] The specifications of 7075 aluminum alloy extruded plate are: length × width × thickness = 170mm × 90mm × 8mm. The edge joints of the two extruded plates to be welded are pre-processed into an inclined joint section 30, and the inclined angle is 30° from the horizontal plane. After cleaning and polishing, they are docked and fixed on the clamping device. Use a special stirring head to make blind holes on the welding surface. The diameter of the blind holes is 2mm, the depth is 4mm, and the interval is 4mm. The ball-milled uniform Al, Sc, Zr mixed powder is filled and compacted, and the groove is sealed. The mixed powder ratio is Al-0.2Sc- 0.1Zr (mass ratio). Use the model SXT-10 gantry mobile friction stir welding machine for single-sided friction stir welding. After the first group of parallel overlapping welding is completed, move the stirring head out of the plate and control the stirring head back to the initial welding position of the first group. , and move a sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com