Multifunctional rectifier bridge jumper system

A bridge jumper and multi-functional technology, which is applied in the changing field of the multi-functional rectifier bridge jumper system, can solve the problems of large forward surge current, inability to resist, and poor heat dissipation, so as to improve forward surge capacity and increase The effective welding area and the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

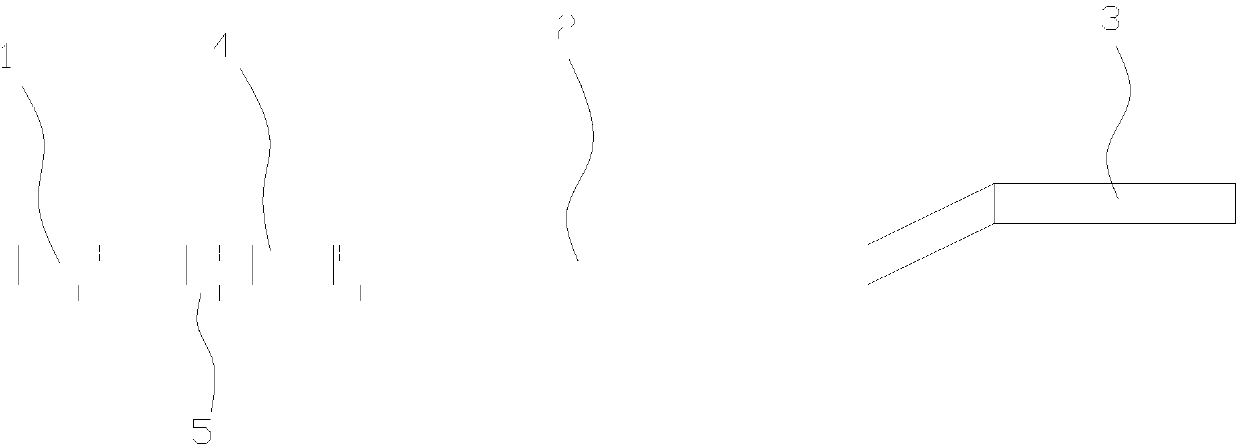

[0013] As shown in the figure, it includes the first working part 1, the connecting part 2 and the second working part 3 connected in sequence, the first working part 1 is used to connect the crystal grains, the second working part 3 is used to connect the frame, and the second working part 3 is used to connect the frame. The top surface of the working part 1 is parallel to the top surface of the working part 2 3; the top surface of the working part 1 is provided with a groove 4, which is convenient for heat dissipation; the bottom surface of the working part 1 is provided with a boss 5 , Improve the welding area.

[0014] The area of the boss 5 ≥ the area of the groove 1; increase the welding area; the working part 1 and the working part 3 are rectangular respectively, and the two ends of the connecting part 2 are respectively connected to the working part 1 One corner of the working part and one side of the working part; the connection is reliable and the stress on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com