Miniature surface mounting semiconductor rectification device

A technology of surface mount and rectifier devices, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., and can solve problems such as reducing the ability of products to withstand surges, uneven current distribution, and increased customer losses. , to achieve the effect of improving tensile strength, product profit and welding process level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

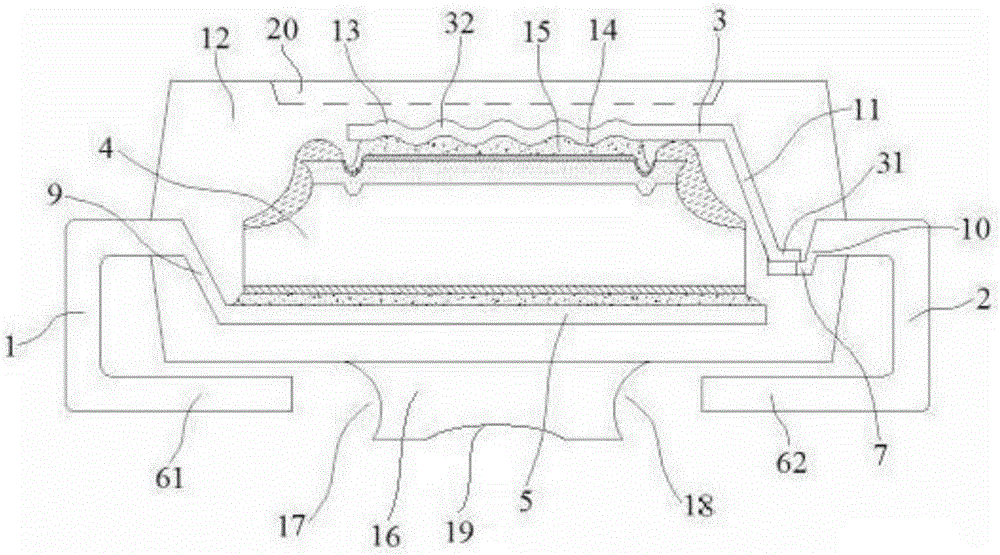

[0019] Embodiment 1: a kind of miniature surface-mounted semiconductor rectifier device, comprises epoxy encapsulation body 12 and the first lead bar 1 that is located in the epoxy encapsulation body 12, the second lead bar 2, connecting piece 3 and diode chip 4, One end of the first lead bar 1 is a support area 5 connected to the diode chip 4, one end of the diode chip 4 is electrically connected to the support area 5 through solder paste, and the other end of the first lead bar 1 is a first pin area 61, The first pin area 61 of the first lead bar 1 serves as the current transmission end of the rectifier;

[0020] One end of the second lead bar 2 is a welding area 7 connected to the first welding end 31 of the connecting piece 3, the other end of the second lead bar 2 is a second pin area 62, and the second lead bar 2 The second pin area 62 is used as the current transmission end of the rectifier; the second welding end 32 of the connecting piece 3 is electrically connected t...

Embodiment 2

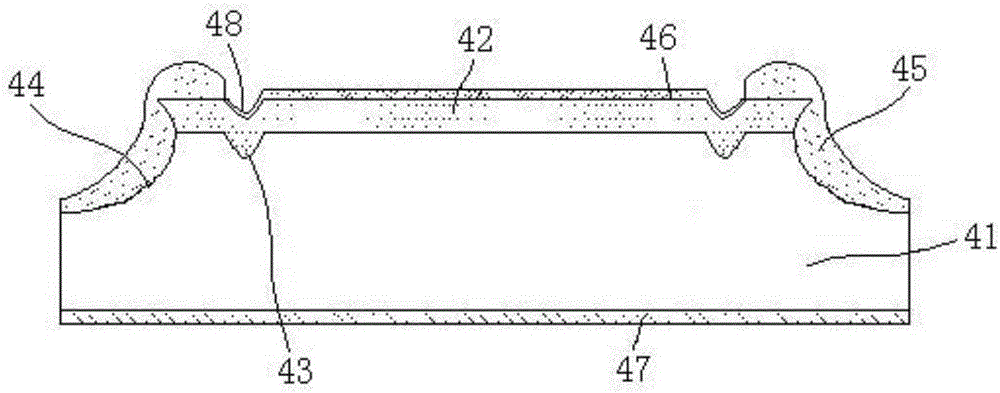

[0026] Embodiment 2: A kind of miniature surface-mounted semiconductor rectifier device, comprises the first lead bar 1, the second lead bar 2, the connection piece 3 and the diode chip 4 that are positioned at the epoxy encapsulation body 12, and this first lead bar 1 one end It is the support area 5 connected with the diode chip 4, one end of the diode chip 4 is electrically connected with the support area 5 through solder paste, the other end of the first lead bar 1 is the first pin area 61, the first lead bar 1 The first pin area 61 serves as the current transmission end of the rectifier;

[0027] One end of the second lead bar 2 is a welding area 7 connected to the first welding end 31 of the connecting piece 3, the other end of the second lead bar 2 is a second pin area 62, and the second lead bar 2 The second pin area 62 is used as the current transmission end of the rectifier; the second welding end 32 of the connecting piece 3 is electrically connected to the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com