Ultra-thin-type surface-mount rectifier

A surface mount, rectifier technology, used in electrical solid devices, semiconductor devices, semiconductor/solid state device components, etc., can solve problems such as reducing the ability of products to withstand surges, uneven current distribution, and increased customer losses. Achieve the effect of improving tensile strength, product profit, and welding process level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

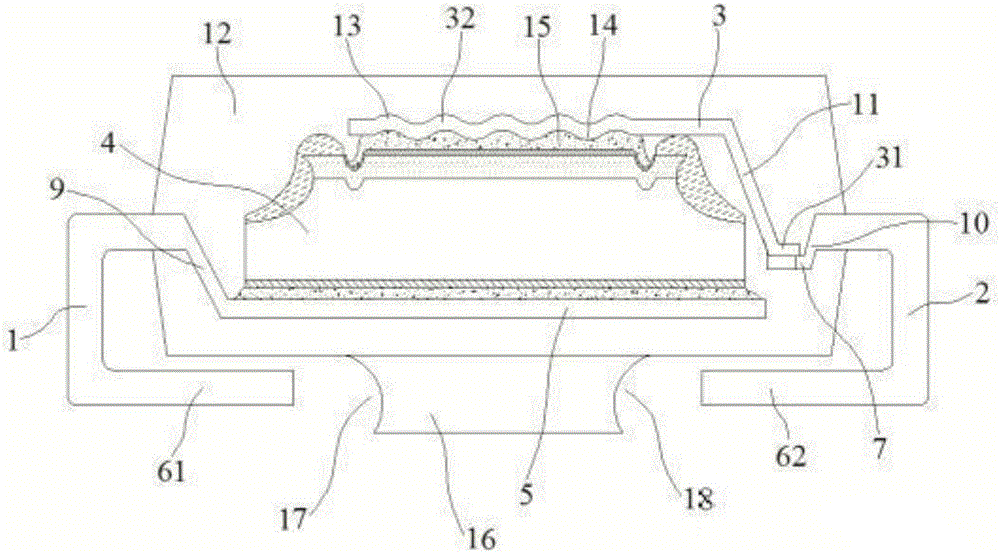

[0024] Embodiment 1: An ultra-thin surface mount rectifier, comprising an epoxy package body 12 and a first lead bar 1, a second lead bar 2, a connecting piece 3 and a diode chip 4 arranged in the epoxy package body 12. One end of the first lead bar 1 is a support area 5 connected to the diode chip 4, one end of the diode chip 4 is electrically connected to the support area 5 through solder paste, and the other end of the first lead bar 1 is a first pin area 61. The first pin area 61 of the first lead bar 1 serves as the current transmission end of the rectifier;

[0025] The two ends of the connecting piece 3 are respectively a first welding end 31 and a second welding end 32. One end of the second lead bar 2 is a welding area 7 connected to the first welding end 31 of the connecting piece 3. The other end of the two lead bars 2 is a second pin area 62, and the second pin area 62 of the second lead bar 2 serves as the current transmission end of the rectifier; the second welding...

Embodiment 2

[0031] Embodiment 2: An ultra-thin surface mount rectifier, comprising a first lead bar 1, a second lead bar 2, a connecting piece 3 and a diode chip 4 in an epoxy package body 12. One end of the first lead bar 1 Is the support area 5 connected to the diode chip 4, one end of the diode chip 4 is electrically connected to the support area 5 through solder paste, and the other end of the first lead bar 1 is the first pin area 61. The first pin area 61 serves as the current transmission end of the rectifier;

[0032] One end of the second lead bar 2 is a welding area 7 connected to the first welding end 31 of the connecting piece 3, and the other end of the second lead bar 2 is a second pin area 62. The second pin area 62 serves as the current transmission end of the rectifier; the second welding end 32 of the connecting piece 3 is electrically connected to the other end of the diode chip 4 by solder paste;

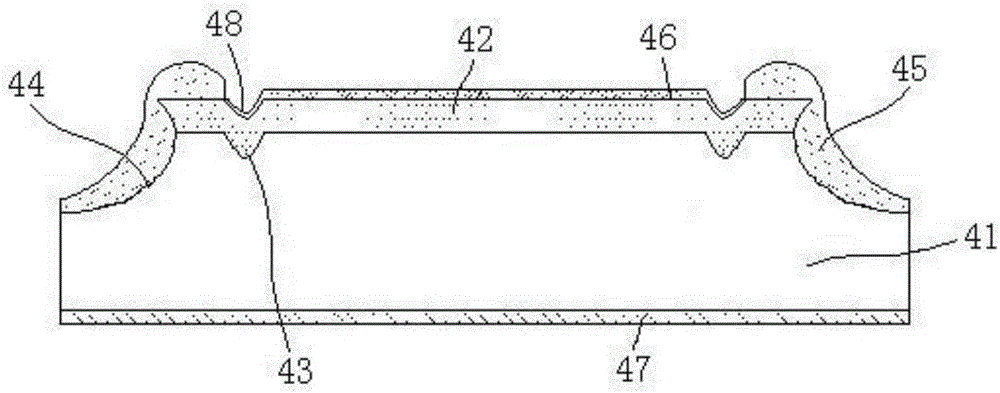

[0033] The diode chip 4 includes a heavily doped P-type monocrystalline sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com