Chewable composition containing phosphosilicate glass and preparation method of chewable composition

A technology of phosphosilicate glass and composition, which is applied in food science, the function of food ingredients, chewing gum, etc., can solve the problems of slow degradation of bioactive glass, affecting the formation speed of mineralized layer, complicated preparation methods, etc., and achieve prevention Oral caries and tooth sensitivity, prevention and treatment of oral infection, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

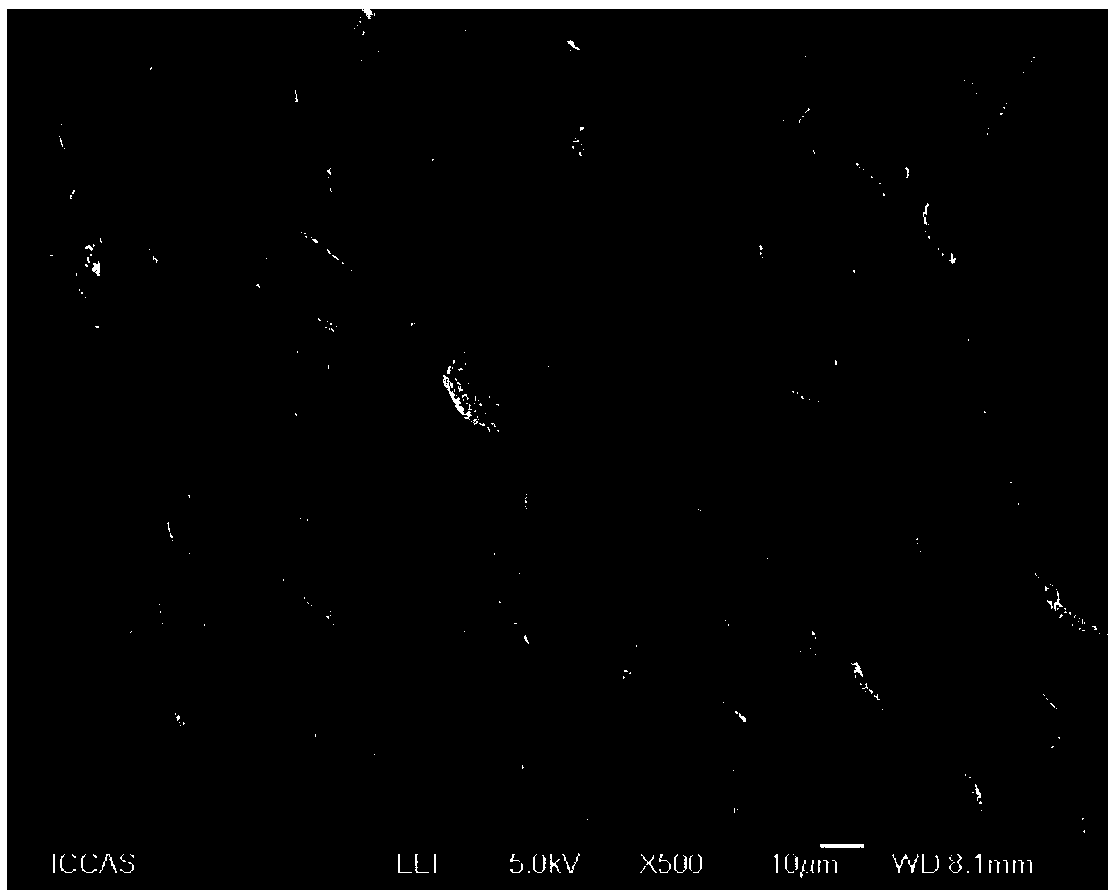

Image

Examples

Embodiment 1

[0053] A calcium phosphosilicate glass chewing gum, which contains 20g of chicle gum base, 50g of calcium phosphosilicate glass, 15g of sugar sweetener, 5g of aspartame, 6g of lemon, 2g of pomelo and 2g of glycerin.

[0054] The preparation method of calcium phosphosilicate glass chewing gum is as follows:

[0055] (1) Heat chicle and glycerin (surfactant) to 145°C to obtain a molten gum base;

[0056] (2) Gradually add calcium phosphosilicate glass, granulated sugar, aspartame, lemon and pomelo to the molten gum base, and stir evenly to obtain a mixed raw material;

[0057] (3) Put the mixed raw materials into an extruder for extrusion molding, cool at 20° C., cut, age at 30° C., and have a relative humidity of 50-55%. The package is available.

Embodiment 2

[0059] A magnesium phosphosilicate glass chewing gum, which contains 40g of polyvinyl acetate, 30g of magnesium phosphosilicate glass, 20g of xylitol and 10g of mint.

[0060] The preparation method of magnesium phosphosilicate glass chewing gum is as follows:

[0061] (1) heating polyvinyl acetate to 135°C to obtain a molten gum base;

[0062] (2) Gradually add magnesium phosphosilicate glass, xylitol and peppermint to the above-mentioned molten gum base, stir evenly, and obtain mixed raw materials;

[0063] (3) Put the mixed raw materials into an extruder for extrusion molding, cool at 15°C, cut, age at 25°C, and have a relative humidity of 50-55%, and the package is available.

Embodiment 3

[0065] A zinc phosphosilicate glass chewing gum, which contains 60g of polyvinyl acetate, 15g of zinc phosphosilicate glass, 20g of oranges and 5g of apples.

[0066] The preparation method of zinc phosphosilicate glass chewing gum is as follows:

[0067] (1) heating polyvinyl acetate to 135°C to obtain a molten gum base;

[0068] (2) Gradually add zinc phosphosilicate glass, oranges and apples to the molten gum base, and stir evenly to obtain mixed raw materials;

[0069] (3) Put the mixed raw materials into an extruder for extrusion molding, cool at 15°C, cut, age at 25°C, and have a relative humidity of 50-55%, and the package is available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com