A light guide plate production and processing technology and its coating and exposure equipment

A light guide plate and coating technology, which is applied in the direction of microlithography exposure equipment, photolithography coating equipment, photolithography process exposure device, etc., can solve the problem of increased cleaning times of the mask, easy contamination of the mask, and scrapping of the mask High efficiency and other problems, to achieve the effect of improving dot processing speed, improving processing efficiency, and strong processing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose of the present invention can be achieved through the following technical solutions:

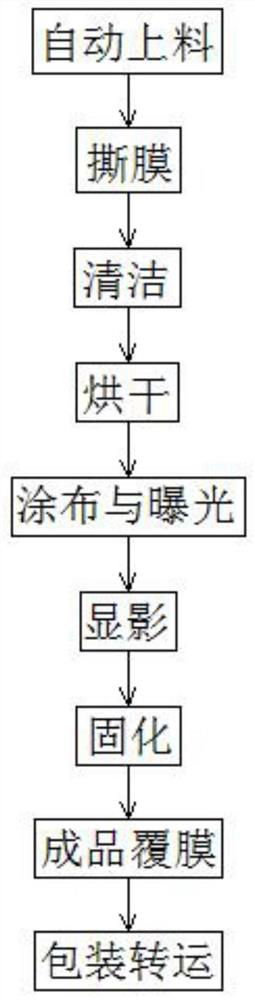

[0034] A kind of light guide plate production and processing technology, see figure 1 , including the following steps:

[0035] Step 1. Automatic loading: place the preliminarily cut substrate 4 on the pallet, and place multiple substrates 4 on the pallet; the automatic grabbing manipulator grabs the substrate 4 on the pallet and places it on the transmission track ;

[0036] Step 2, tearing the film: when the substrate 4 on the transmission track passes through the automatic film tearing machine, the automatic film tearing machine tears off the protective film on the substrate 4; then the substrate 4 continues to be conveyed backward with the transmission track;

[0037] Step 3, cleaning: when the substrate 4 passes under the automatic cleaning machine with the conveying track, the automatic cleaning machine adds cleaning liquid to the substrate 4, and the cleaning liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com