Formaldehyde purifying fiber and preparation method thereof

A formaldehyde purification and fiber technology, applied in the field of formaldehyde removal, can solve the problems of dust pollution, heavy quality, etc., and achieve the effect of high load capacity, light weight and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of formaldehyde purification fiber, comprising:

[0047] Polymethyl methacrylate is dissolved in N,N-dimethylformamide (DMF) to prepare spinning solution, wherein the mass concentration of polymethyl methacrylate in the spinning solution is 30%, on the electrospinning machine Spinning was carried out, and then dried in vacuum for 6 hours to obtain white polymethyl methacrylate fibers.

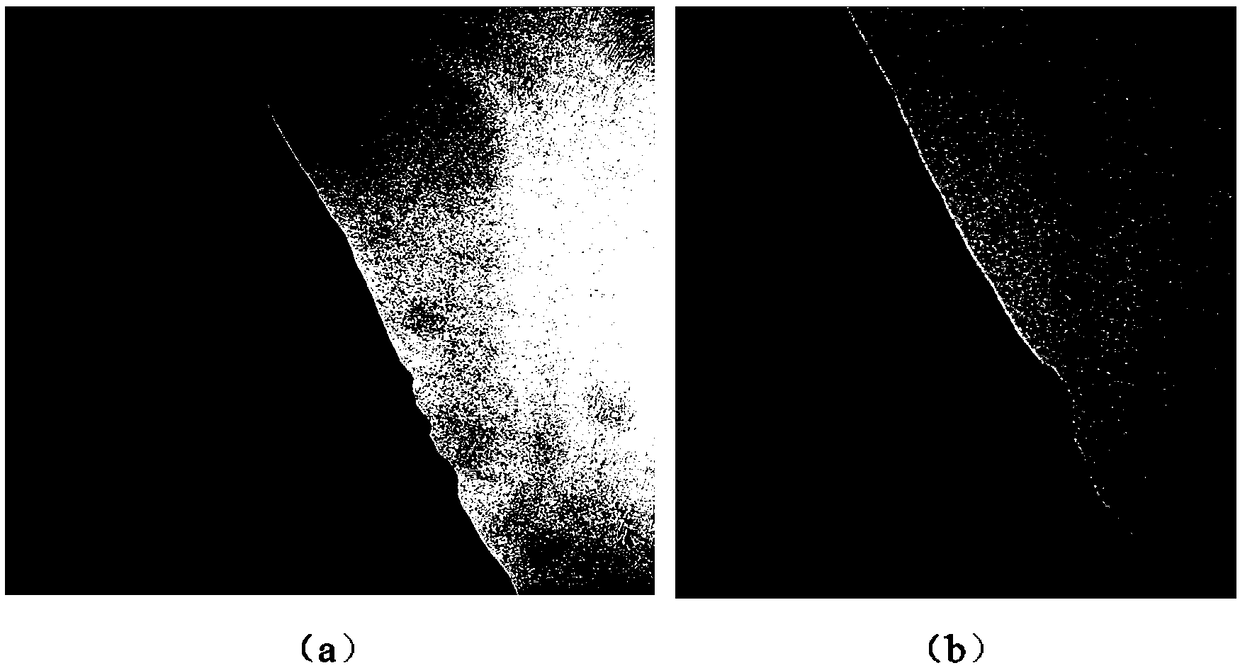

[0048] Mix 22.5mL of distilled water, 10mL of absolute ethanol, 0.5mL of ammonia water, and 0.125g of dopamine hydrochloride evenly to prepare a dopamine-modified solution. Place polymethyl methacrylate fibers in the dopamine-modified solution and place them on a shaker at room temperature for 12 hours. Under alkaline conditions, dopamine oxidizes and self-polymerizes on fibers, washes with water until the aqueous solution is colorless, then soaks in 15% isopropanol aqueous solution for 20 minutes to remove unreacted dopamine, rinses with water for 3-5 times , freez...

Embodiment 2

[0051] A preparation method of formaldehyde purification fiber, comprising:

[0052] Polymethyl methacrylate and polyvinylidene fluoride were dissolved in N,N-dimethylformamide (DMF) to prepare a spinning solution, wherein the mass concentration of polymethyl methacrylate in the spinning solution was 15%, The mass concentration of polyvinylidene fluoride is 20%. Spinning was carried out on an electrospinning machine, and the electrospinning parameters were: anode voltage 8kV, cathode voltage -4kV, sample injection speed 0.4ml / h, rotation speed 60 rpm, spinning temperature 20°C, humidity 40%. The spun fibers were vacuum-dried at 50° C. for 7 hours to obtain polymethyl methacrylate fibers.

[0053] Mix 15mL of distilled water, 5mL of absolute ethanol, 0.3mL of ammonia water, and 0.05g of dopamine hydrochloride evenly to prepare a dopamine modification solution. Put polymethyl methacrylate fibers in the dopamine modification, soak them at room temperature for 24 hours, and then ...

Embodiment 3

[0056] A preparation method of formaldehyde purification fiber, comprising:

[0057] Mix polyvinylpyrrolidone and polyvinylidene fluoride at a mass ratio of 3:2, and dissolve them in chloroform to prepare a spinning solution, wherein the mass concentration of polyvinylpyrrolidone in the spinning solution is 10%. Spinning was carried out on an electrospinning machine, and the electrospinning parameters were: anode voltage 25kV, cathode voltage -2kV, sample injection speed 1ml / h, rotation speed 180 rpm, spinning temperature 30°C, humidity 60%. The spun fiber is at 50μW / cm 2 Irradiation was carried out for 4 hours under the intensity of ultraviolet light, and a cross-linking reaction was carried out to prepare the second polymer fiber.

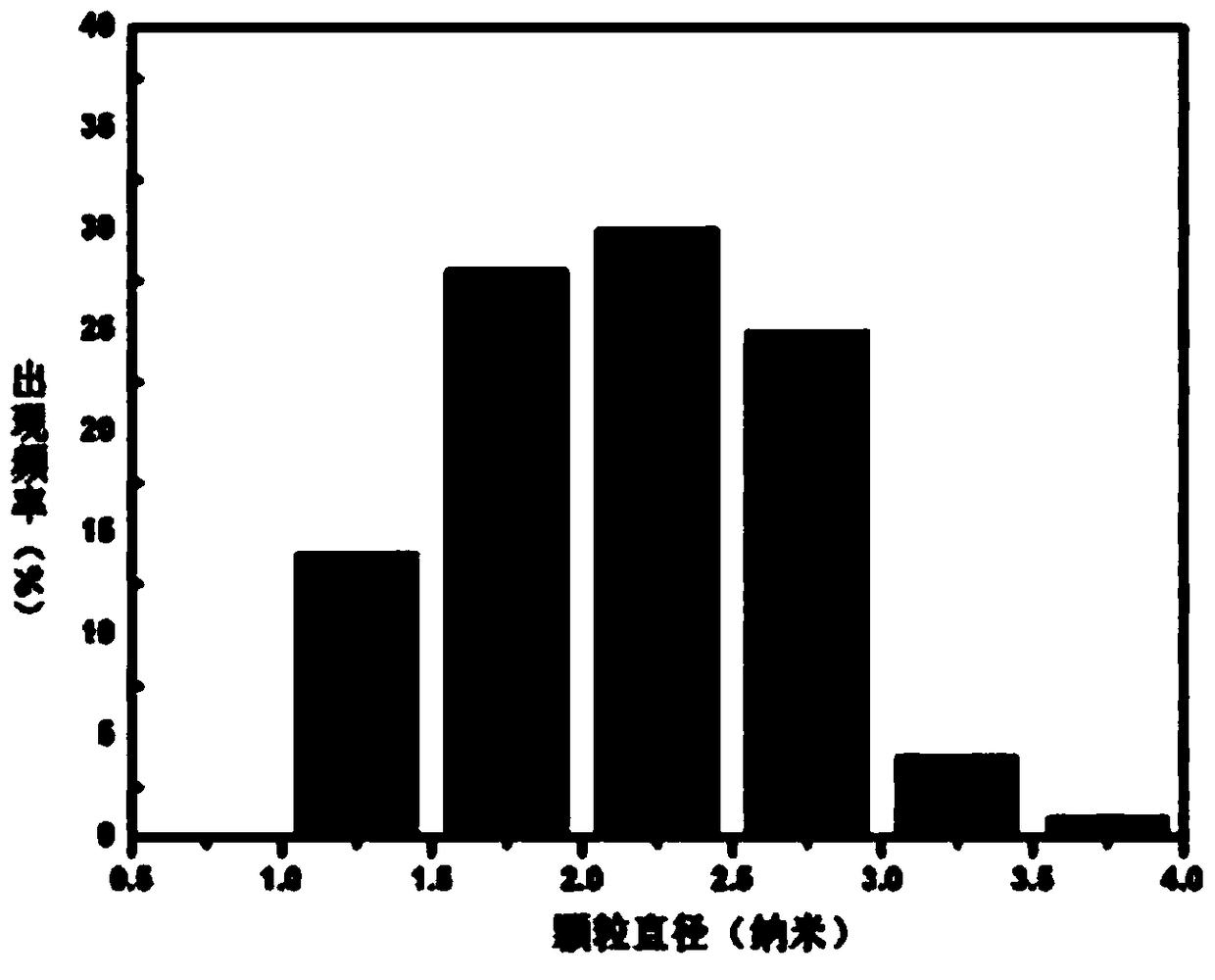

[0058] Prepare chloroplatinic acid solution, wherein the molar concentration of platinum ions is 0.035mol / L. The second polymer fiber is placed in it, placed on a shaker at room temperature and soaked for 80 hours, then soaked in a 0.03 mol / L s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com