Waste tire handling technology

A technology for processing waste tires, which is applied in the fields of processing hydrocarbon oil, petroleum industry, special forms of dry distillation, etc., can solve the problems of low equipment level, difficulty, and increased expenditure, and achieve guaranteed yield, improved pyrolysis reaction, and heating speed accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

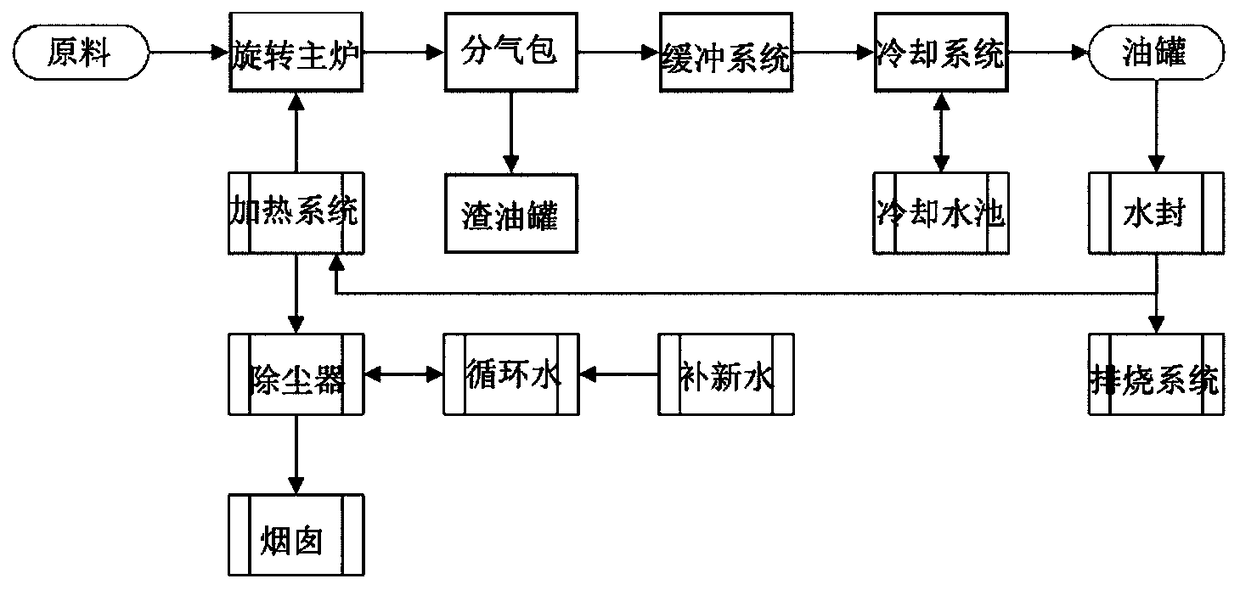

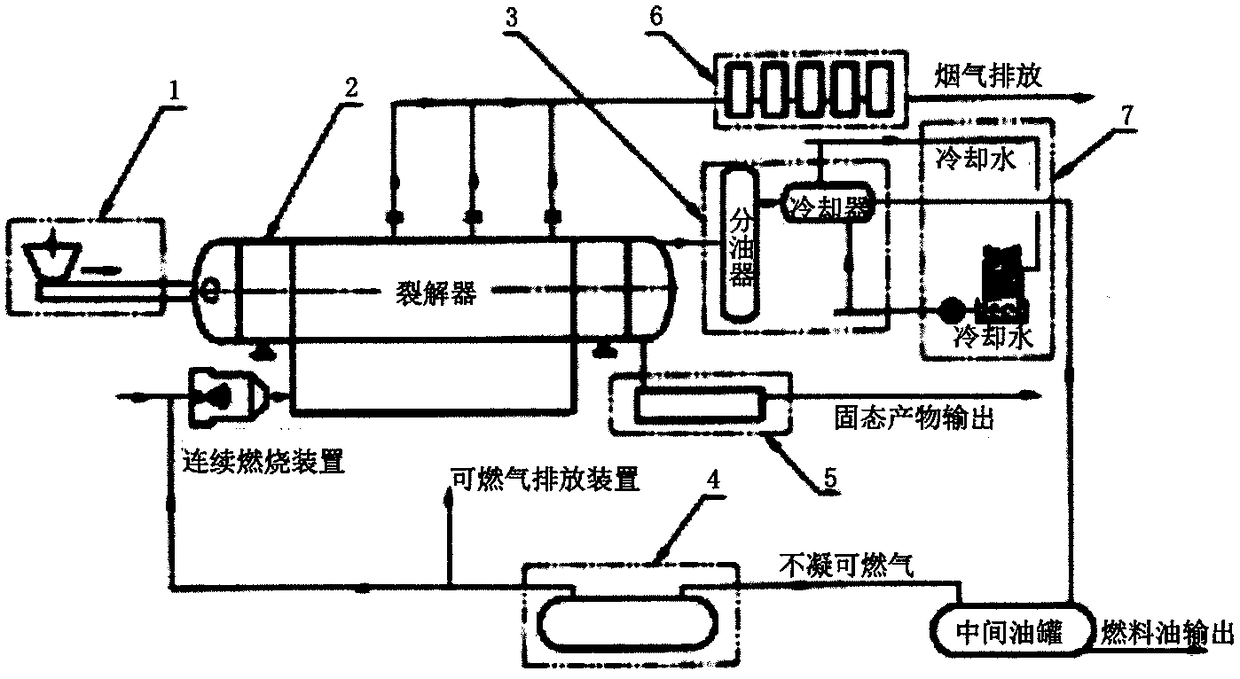

Method used

Image

Examples

Embodiment 1

[0026] Put the waste tires into a wire drawing machine to remove the steel wires, clean the tires from which the steel wires have been removed, remove the stains, and then cut them into 25X45mm rubber blocks. The rubber block is frozen and pulverized, and the freezing temperature is controlled at -160°C. Put the rubber crumbs into the reaction kettle, and distill the oil vapor through catalytic heating. The oil and gas pass through the light and heavy component separation device, and the light component enters the condenser. At the same time, carbon black is generated during combustion and discharged, condensed into liquid oil, and the non-liquefiable part Through the gas purification system, it is input into the heating system for combustion, and the exhaust gas generated by combustion is dedusted by the dust removal system and discharged after meeting the national requirements.

Embodiment 2

[0028] Put the waste tires into a wire drawing machine to remove the steel wires, clean the tires from which the steel wires have been removed, remove the stains, and then cut them into 30X35mm rubber blocks. The rubber blocks were frozen and pulverized, and the freezing temperature was controlled at -163°C. Put the rubber crumbs into the reaction kettle, and distill the oil vapor through catalytic heating. The oil and gas pass through the light and heavy component separation device, and the light component enters the condenser. At the same time, carbon black is generated during combustion and discharged, condensed into liquid oil, and the non-liquefiable part Through the gas purification system, it is input into the heating system for combustion, and the exhaust gas generated by combustion is dedusted by the dust removal system and discharged after meeting the national requirements.

Embodiment 3

[0030] Put the waste tires into a wire drawing machine to remove the steel wires, clean the tires from which the steel wires have been removed, remove the stains, and then cut them into 35X25mm rubber blocks. The rubber blocks were frozen and pulverized, and the freezing temperature was controlled at -165°C. Put the rubber crumbs into the reaction kettle, and distill the oil vapor through catalytic heating. The oil and gas pass through the light and heavy component separation device, and the light component enters the condenser. At the same time, carbon black is generated during combustion and discharged, condensed into liquid oil, and the non-liquefiable part Through the gas purification system, it is input into the heating system for combustion, and the exhaust gas generated by combustion is dedusted by the dust removal system and discharged after meeting the national requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com