Low-solid no-clean soldering flux and preparation method thereof

A no-cleaning, flux technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of substandard environmental protection, excessive residues, and high corrosiveness, and achieve easy industrial production, simple preparation process, and excellent electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

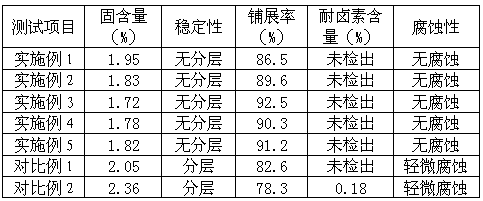

Examples

Embodiment 1

[0029] The low-solid no-cleaning flux of this embodiment consists of the following raw materials in parts by weight: 25 parts of resin, 5 parts of resin emulsifier, 3 parts of o-hydroxybenzoic acid, 2 parts of fluoroboric acid, 3 parts of salicylic acid, three parts of polyethylene 3 parts of imine, 2 parts of N,N-dimethylethanolamine, 0.3 parts of film former, 0.8 parts of surfactant, 1.2 parts of corrosion inhibitor, 20 parts of cosolvent.

[0030] Wherein, the resin is selected from at least one of polyamide resin, perhydrogenated rosin resin and modified rosin resin.

[0031] Wherein, the resin emulsifier is selected from at least one of hydrogenated methyl abietate, pentaerythritol palmitate and diisodecyl phthalate.

[0032] Wherein, the film-forming agent is selected from at least one of polyethylene glycol, polyacrylic acid, carboxymethylcellulose and polyvinylpyrrolidone.

[0033] Wherein, the surfactant is sodium dodecylbenzenesulfonate or fatty acid glyceride.

[...

Embodiment 2

[0042] The low-solid no-cleaning flux of the present embodiment is composed of the following raw materials in parts by weight: 35 parts of resin, 10 parts of resin emulsifier, 8 parts of o-hydroxybenzoic acid, 4 parts of fluoboric acid, 6 parts of salicylic acid, three polyethylene 6 parts of imine, 5 parts of N,N-dimethylethanolamine, 0.6 parts of film former, 1.4 parts of surfactant, 1.6 parts of corrosion inhibitor, 35 parts of cosolvent.

[0043] Wherein, the resin is selected from at least one of polyamide resin, perhydrogenated rosin resin and modified rosin resin.

[0044] Wherein, the resin emulsifier is selected from at least one of hydrogenated methyl abietate, pentaerythritol palmitate and diisodecyl phthalate.

[0045] Wherein, the film-forming agent is selected from at least one of polyethylene glycol, polyacrylic acid, carboxymethylcellulose and polyvinylpyrrolidone.

[0046] Wherein, the surfactant is sodium dodecylbenzenesulfonate or fatty acid glyceride.

[...

Embodiment 3

[0055] The low-solid no-cleaning flux of this embodiment is composed of the following raw materials in parts by weight: 30 parts of resin, 7.5 parts of resin emulsifier, 5.5 parts of o-hydroxybenzoic acid, 3 parts of fluoboric acid, 4.5 parts of salicylic acid, three polyethylene 4.5 parts of imine, 3.5 parts of N,N-dimethylethanolamine, 0.4 parts of film former, 1.1 parts of surfactant, 1.4 parts of corrosion inhibitor, and 27 parts of cosolvent.

[0056] Wherein, the resin is selected from at least one of polyamide resin, perhydrogenated rosin resin and modified rosin resin.

[0057] Wherein, the resin emulsifier is selected from at least one of hydrogenated methyl abietate, pentaerythritol palmitate and diisodecyl phthalate.

[0058] Wherein, the film-forming agent is selected from at least one of polyethylene glycol, polyacrylic acid, carboxymethylcellulose and polyvinylpyrrolidone.

[0059] Wherein, the surfactant is sodium dodecylbenzenesulfonate or fatty acid glyceride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com