Method for processing EPP loudspeaker box cone paper

A processing method and drum paper technology, applied in electrical components, sensors, etc., can solve the problems of poor high temperature resistance, poor acid and alkali resistance, etc., and achieve the effects of excellent physical properties, enhanced use effect, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

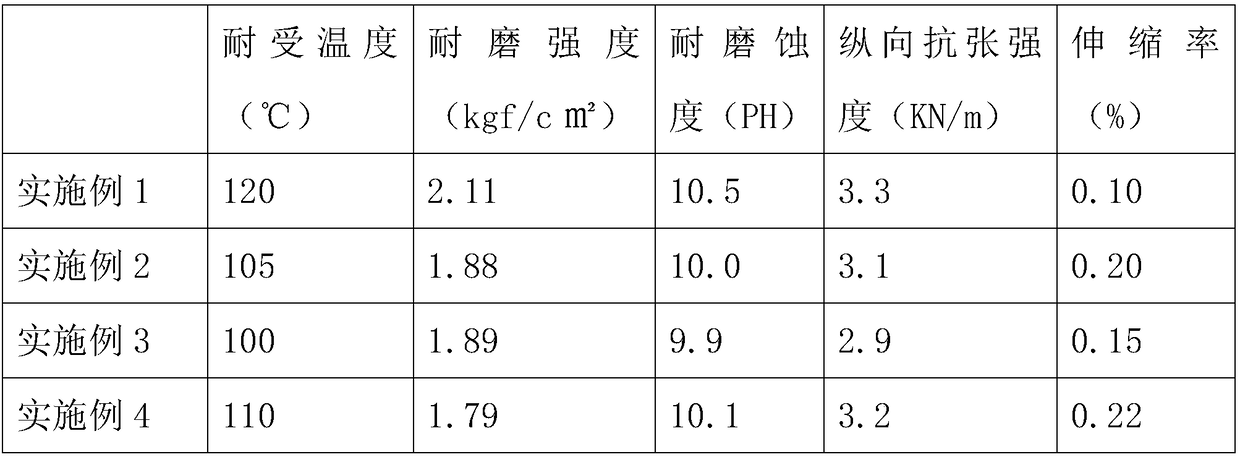

Embodiment 1

[0048] The invention discloses a processing method of EPP sound box drum paper, which is prepared from the following raw materials according to parts by weight: 25 parts of EPP, 3 parts of short fiber, 50 parts of paper pulp, 5 parts of fluorine phlogopite, and 5 parts of barium sulfate , 3 parts of boron carbide, 3 parts of silicon carbide, 5 parts of silicon nitride, 15 parts of aluminum oxide, 3 parts of adhesive, and 7 parts of foaming agent.

[0049] The EPP is high melt strength polypropylene, the short fiber is glass fiber, the pulp is wood pulp and straw pulp, the adhesive is polyurethane adhesive, and the foaming agent is positive pentane.

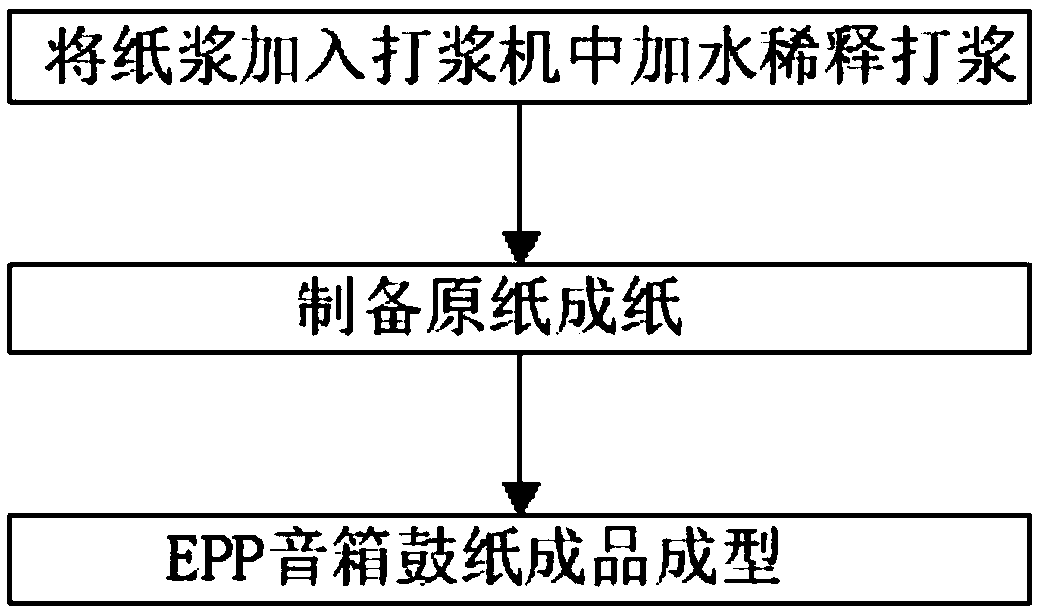

[0050] The present invention also discloses a processing method of the above-mentioned EPP sound box drum paper, and the specific steps are as follows:

[0051] (1), beating

[0052] Add wood pulp and straw pulp into the beater, add water to dilute the beating, and the beating degree is 260SR;

[0053] (2), prepare base paper i...

Embodiment 2

[0062] The invention discloses a processing method of EPP sound box drum paper, which is prepared from the following raw materials in parts by weight: 20 parts of EPP, 4 parts of short fiber, 45 parts of paper pulp, 6 parts of fluorophlogopite powder and 3 parts of barium sulfate , 5 parts of boron carbide, 1 part of silicon carbide, 8 parts of silicon nitride, 10 parts of aluminum oxide, 5 parts of adhesive, and 5 parts of foaming agent.

[0063] The EPP is high melt strength polypropylene, the short fibers are carbon fibers, the pulp is wood pulp and bamboo pulp, the adhesive is polyvinyl acetate adhesive, and the foaming agent is Trichlorofluoromethane.

[0064] As preferably, the present invention also discloses the processing method of above-mentioned EPP sound box drum paper, and concrete steps are as follows:

[0065] (1), beating

[0066] Add wood pulp and bamboo pulp into the beater and add water to dilute the beating, and the beating degree is 260SR;

[0067] (2),...

Embodiment 3

[0076] The invention discloses a processing method of EPP sound box drum paper, which is prepared from the following raw materials in parts by weight: 30 parts of EPP, 1 part of short fiber, 65 parts of paper pulp, 4 parts of fluorophlogopite powder and 7 parts of barium sulfate , 1 part of boron carbide, 5 parts of silicon carbide, 2 parts of silicon nitride, 20 parts of aluminum oxide, 1 part of adhesive, and 9 parts of foaming agent.

[0077] The EPP is high melt strength polypropylene, the short fibers are basalt fibers, the pulp is bamboo pulp, the adhesive is polyvinyl acetate adhesive, and the foaming agent is n-hexane .

[0078] The present invention also discloses a processing method of the above-mentioned EPP sound box drum paper, and the specific steps are as follows:

[0079] (1), beating

[0080] Add the bamboo pulp into the beater and add water to dilute the beating, and the beating degree is 280SR;

[0081] (2), prepare base paper into paper

[0082] (2.1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com