Novel infrared detector BIB silicon epitaxial wafer manufacturing method

A technology of infrared detectors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., capable of solving problems such as high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

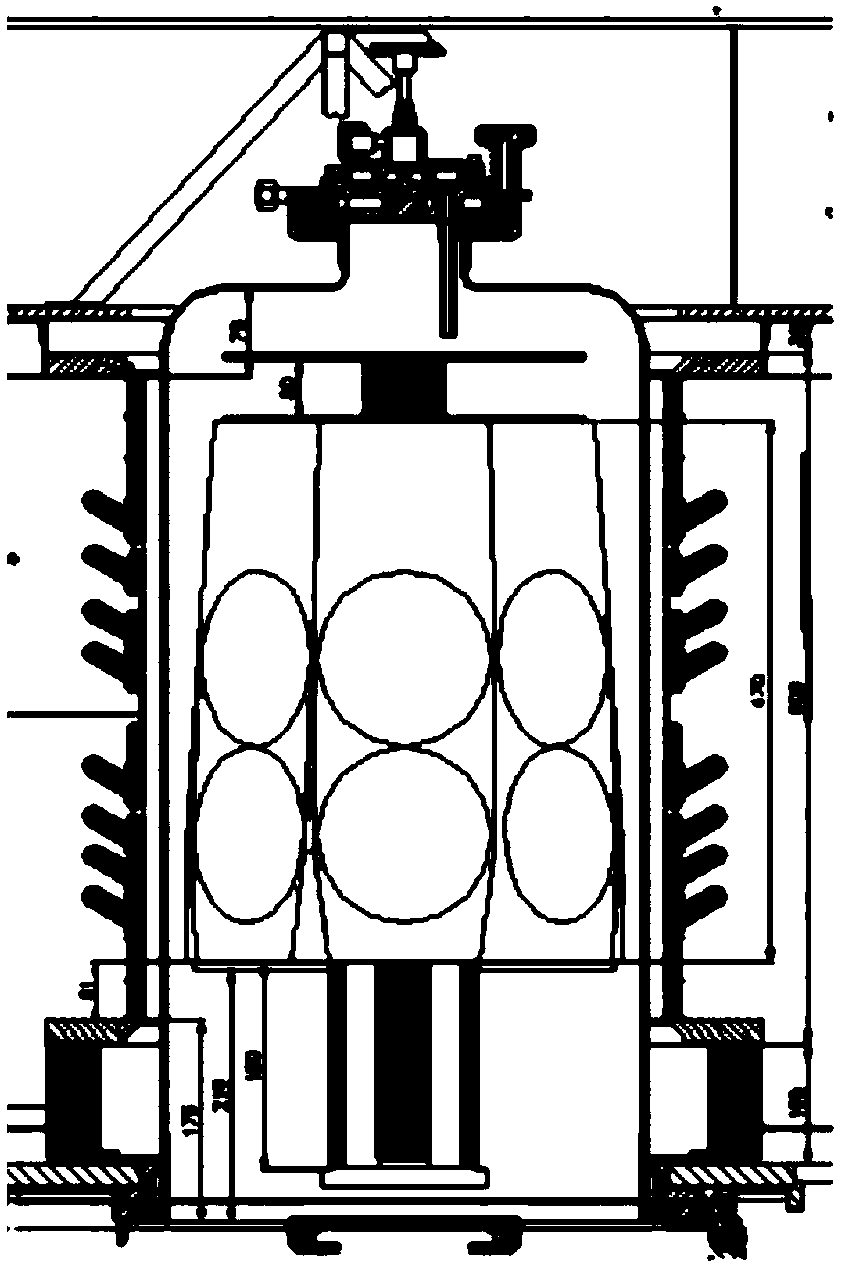

[0020] see figure 1 As shown, the equipment used in the present invention is Italian PE-2061S atmospheric pressure silicon epitaxial growth equipment, the high-purity graphite base is used as a high-frequency induction heating body, and the purity of the main carrier gas H2 is above 99.9999%.

[0021] Equipment preparation includes,

[0022] Reactor cleaning: The quartz bell jar and the quartz parts used in the reaction chamber must be carefully cleaned before epitaxy. The substrate removes the deposition residue on the inner wall of the quartz bell jar and the quartz parts to reduce the self-doping of the cavity.

[0023] High-temperature treatment in the reaction chamber: Before epitaxial growth, the graphite base must be subjected to HCl high-temperature treatment to remove residual reactants adsorbed by the base and cavity, and deposit a layer of intrinsic polysilicon.

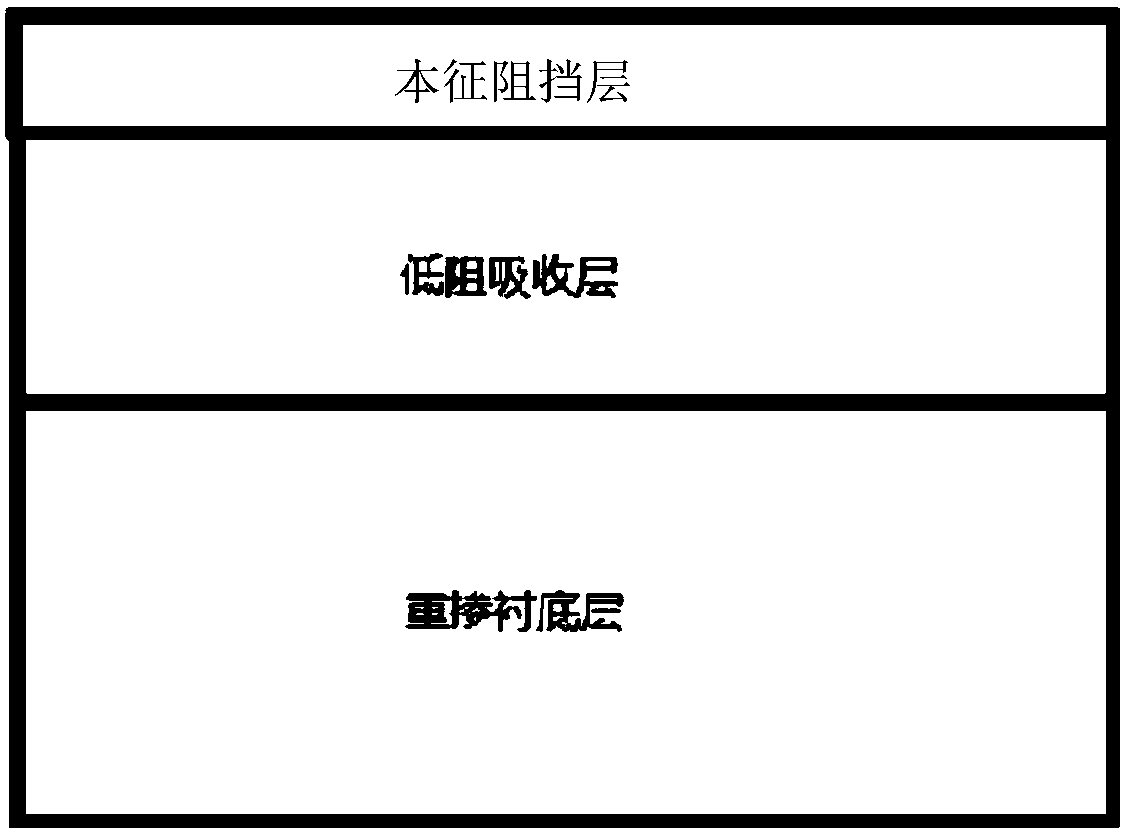

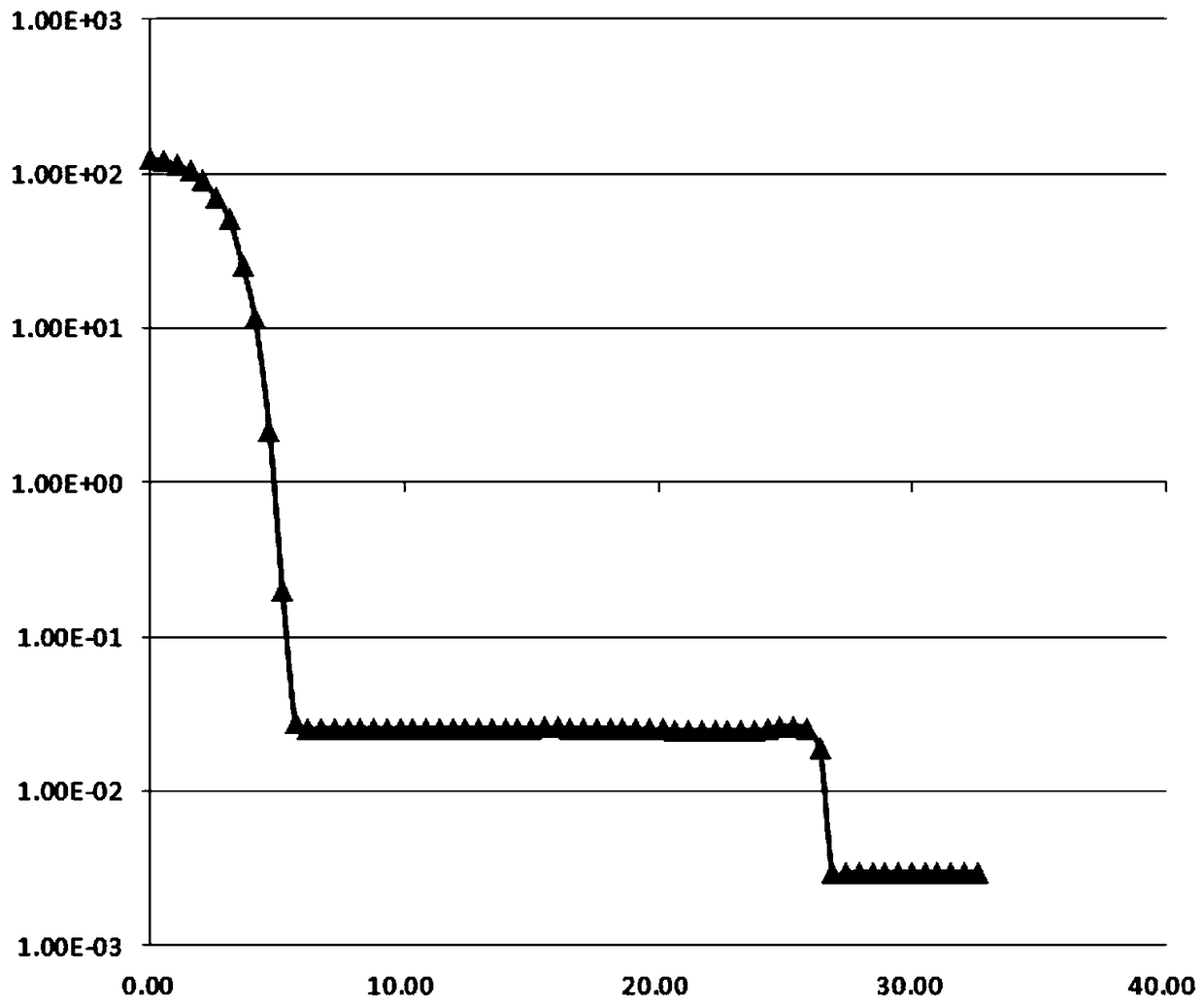

[0024] Please reunite image 3 and Figure 4 As shown, the steps of the manufacturing method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com