Laser treatment method for improving biocompatibility of magnesium alloy

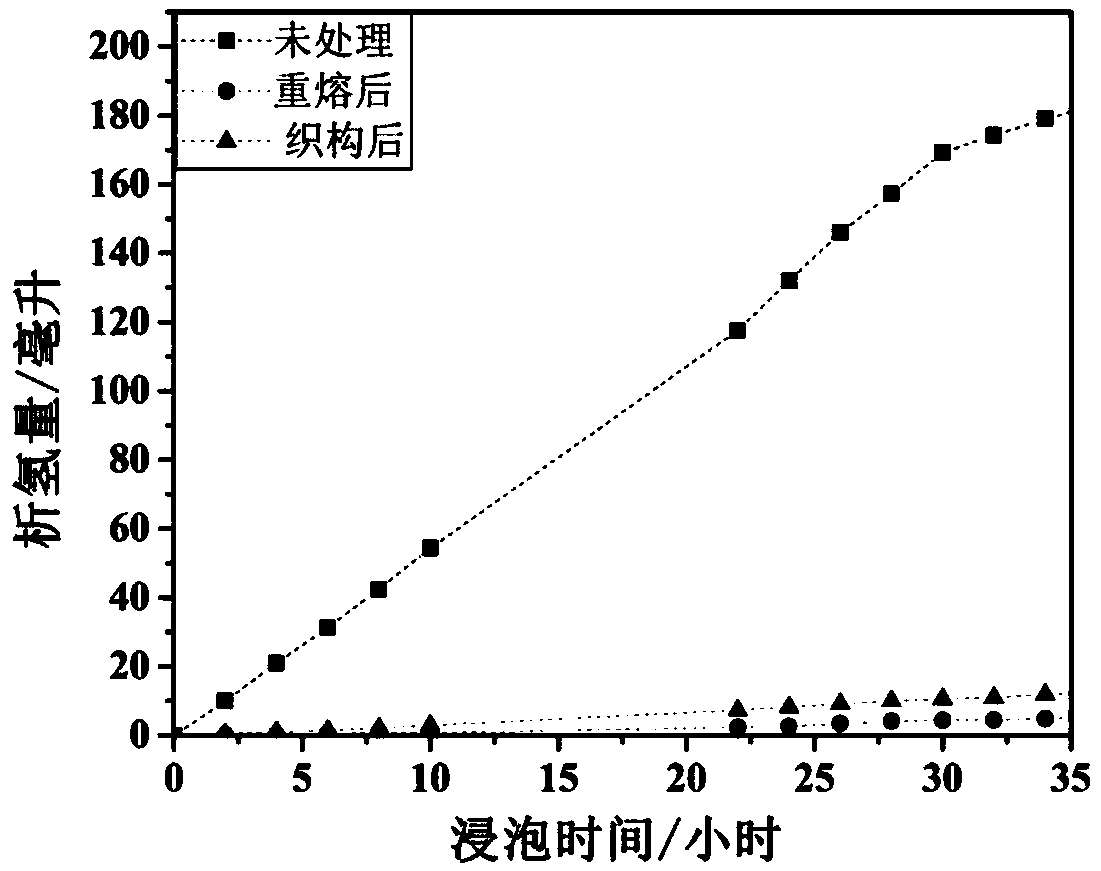

A biocompatible, laser processing technology, applied in the field of material surface processing, can solve the problems of pH rise, fast corrosion rate, patient alkali poisoning, etc., achieve fast processing speed, improve production efficiency, thermal damage and thermal impact small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Step 1: Grinding and polishing the Mg-6Gd-0.6Ca magnesium alloy sample to 1000 mesh, ultrasonic cleaning with alcohol for 5 minutes, and drying;

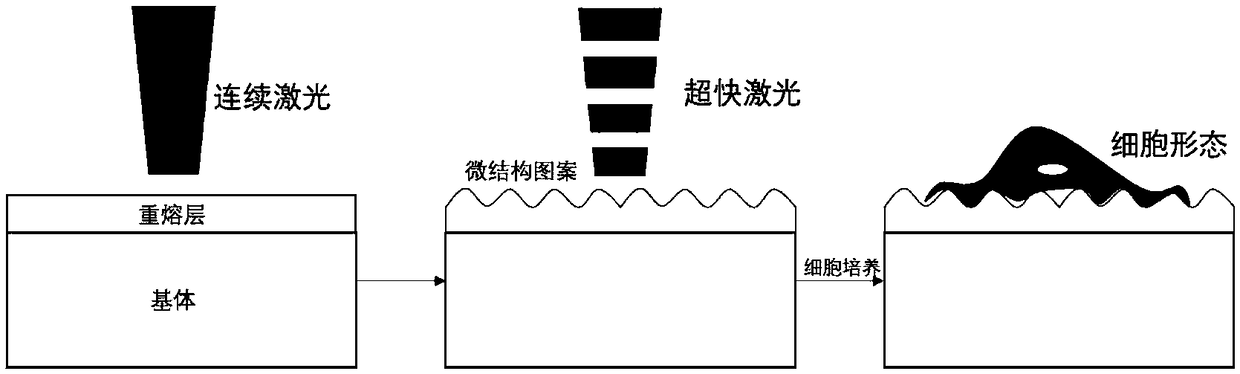

[0032] (2) Step 2, place the magnesium alloy sample under a continuous laser with a wavelength of 1060nm, set the laser processing parameters as follows: power 80W, scanning speed 100mm / s, spot overlap rate 40%, start the equipment, perform laser remelting, remelting During the process, argon protection is used to obtain a remelted layer on the surface of the magnesium alloy sample;

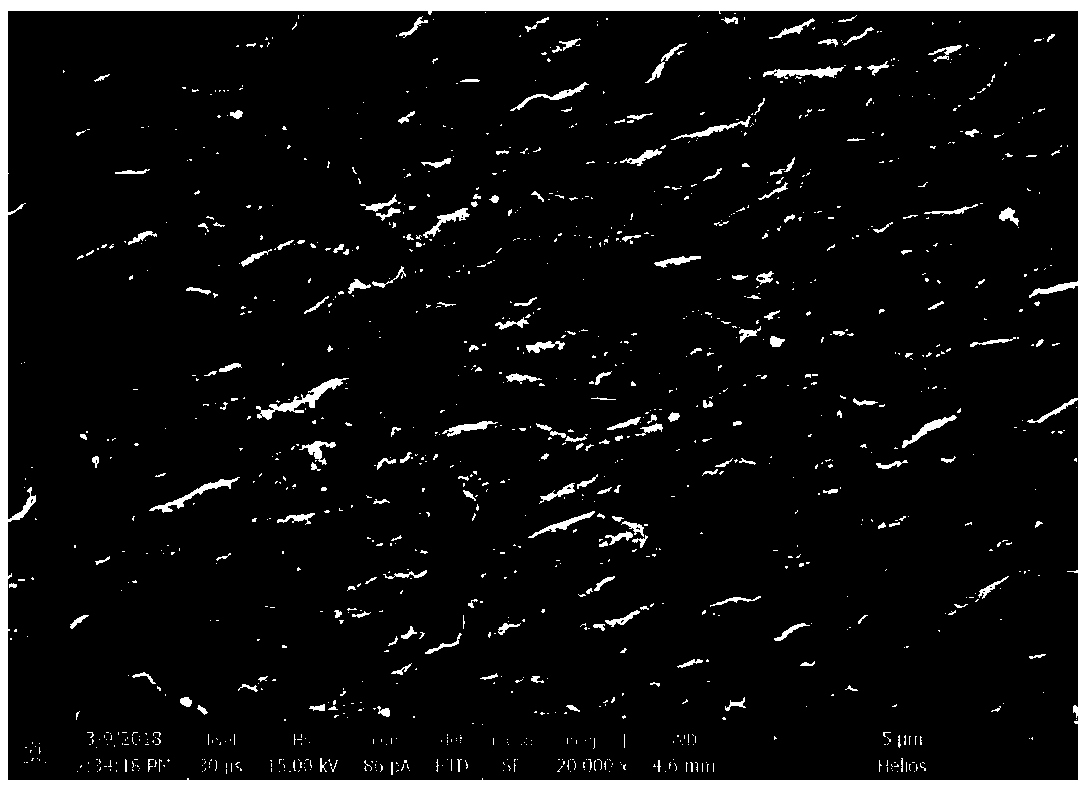

[0033] (3) Step 3, place the magnesium alloy sample after surface remelting under a femtosecond laser (wavelength 1064nm), and perform laser texture treatment on the surface of the magnesium alloy after laser remelting treatment, and the laser processing parameters are set to: power 8W, pulse width 500fs, frequency 400kHz, scan speed 800mm / s, scan interval 70μm, scan 5 times, and obtain LIPSS structure on the surface of magnesium alloy;

[...

Embodiment 2

[0036] (1) Step 1: Grinding and polishing the AZ31 magnesium alloy sample to 1000 mesh, ultrasonic cleaning with alcohol for 5 minutes, and drying;

[0037] (2) Step 2, place the magnesium alloy sample under a continuous laser with a wavelength of 1060nm, set the laser processing parameters as follows: power 200W, scanning speed 300mm / s, spot overlap rate 20%, start the equipment, perform laser remelting, remelting During the process, argon protection is used to obtain a remelted layer on the surface of the magnesium alloy sample;

[0038] (3) Step 3, place the magnesium alloy sample after surface remelting under a femtosecond laser (wavelength 1064nm), and perform laser texture treatment on the surface of the magnesium alloy after laser remelting treatment, and the laser processing parameters are set to: power 20W, pulse width 500fs, frequency 400kHz, scan speed 800mm / s, scan interval 70μm, scan 5 times, and obtain microcone structure on the surface of magnesium alloy;

[00...

Embodiment 3

[0041] (1) Step 1: Grinding and polishing the Mg-3Sn-0.5Mn magnesium alloy sample to 1000 mesh, ultrasonic cleaning with alcohol for 5 minutes, and drying;

[0042] (2) Step 2, place the titanium alloy sample under a continuous laser with a wavelength of 1060nm, set the laser processing parameters as follows: power 200W, scan speed 70mm / s, spot overlap rate 70%, start the equipment, carry out laser remelting, remelting During the process, argon protection is used to obtain a remelted layer on the surface of the titanium alloy sample;

[0043] (3) In step 3, the magnesium alloy sample after surface remelting is placed under a picosecond laser (wavelength 1064nm), and the laser texture treatment is performed on the surface of the magnesium alloy after laser remelting treatment. The laser processing parameters are set to: power 7W, pulse width 10ps, frequency 1MHz, scan speed 2000mm / s, scan interval 20μm, scan 10 times, and obtain irregular structure on the surface of magnesium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com