Water-based plastic gravure table printing ink

A plastic and gravure technology, applied in ink, household utensils, applications, etc., can solve problems such as non-applicability of environmental protection regulations and policies, impact on workers' physical and mental health, and residual odor of solvents, etc., to achieve low solvent residues and reduce emissions of VOC substances , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

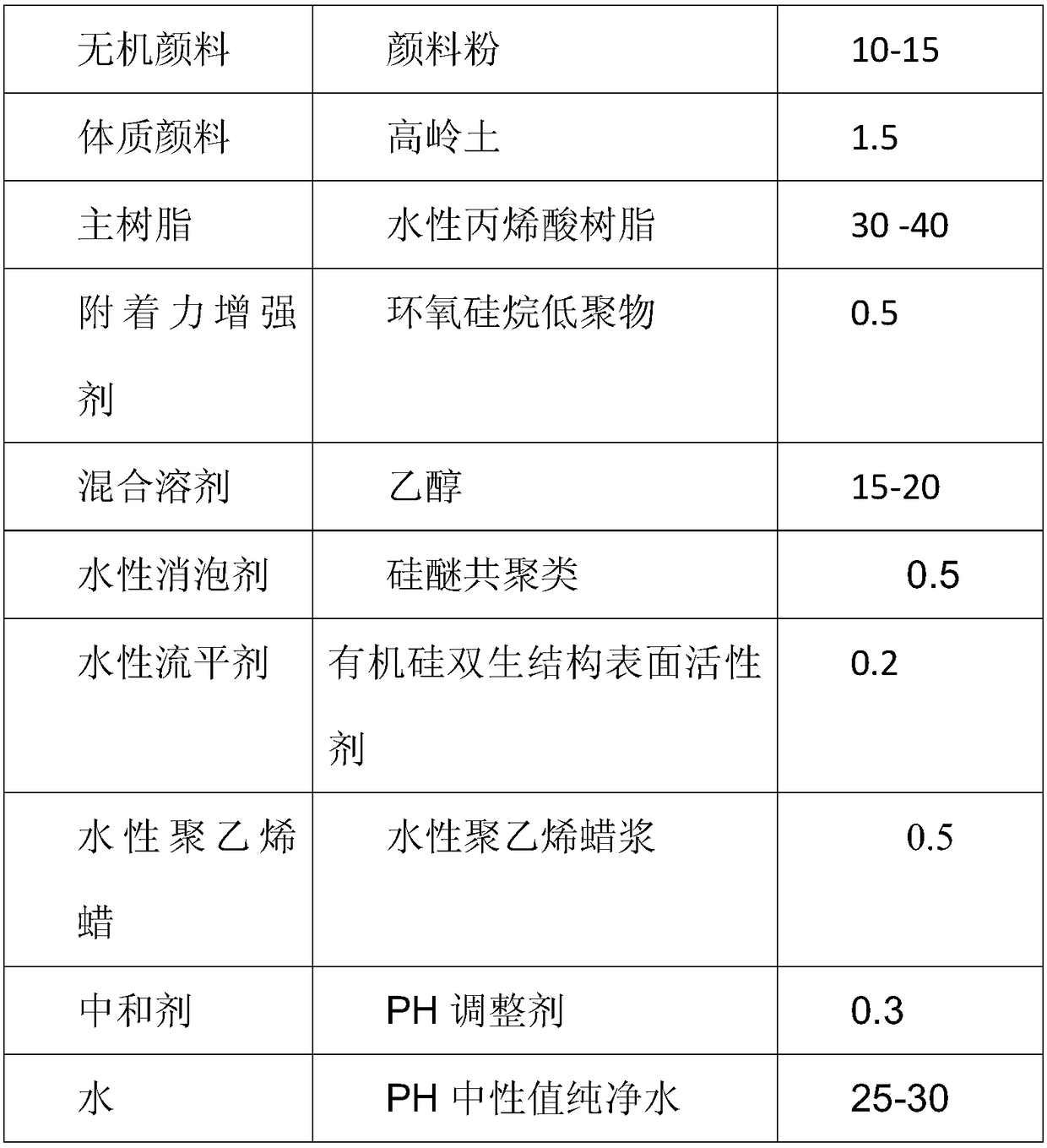

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the effect of each component in the formula of the present invention is, main body resin is used as the main film-forming body of printing ink, has excellent compatibility and dispersibility to pigment, is soluble in various alcoholic solvents and water, viscosity Suitable, good dry release, good compatibility with other resins or additives, good chemical properties and stability, excellent fluidity at low temperature; extender pigments can improve printing scratch resistance, maintain ink stability and improve The printing ink is dry; the adhesion enhancer can improve the adhesion of the ink on a certain printing substrate; the water-based defoamer can suppress and defoam, and the water-based leveling agent can effectively reduce the surface Tension, water-based polyethylene wax can improve the scraper suitability of ink printing, reduce the wear of scraper and plate, and improve the film-forming anti-adhesion of printed matter; the neutralizer can improve...

Embodiment 2

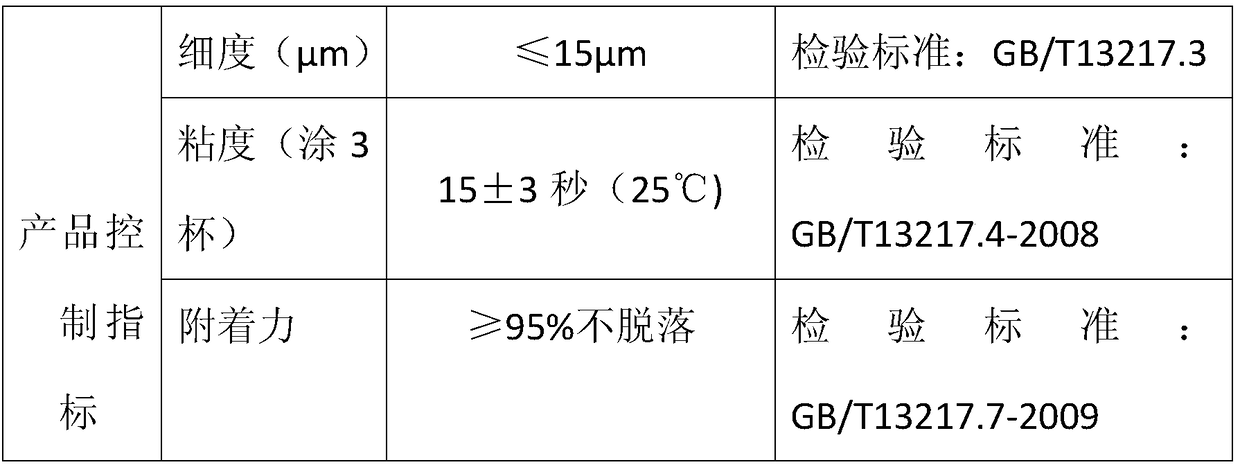

[0025] Embodiment 2: the present invention adopts novel water-based ink production process, mainly uses equipment such as high-speed disperser, sand mill and filter; Earlier part solvent and water are dropped in the mixing tank, under the situation of low-speed dispersion, slowly drop into The main resin and defoamer, and then adjust the speed to a high speed to disperse evenly until the resin is completely dissolved or mixed evenly, and then at the same stirring speed, add pigments, extender pigments, and water-based polyethylene wax to disperse and stir for 30 minutes. Then transfer the dispersed and mixed semi-finished product to the sand mill, grind it two to three times, and then use the scraper fineness meter to measure the fineness of the ink, which reaches or is less than 15 μm; then transfer to the next process and put in the remaining solvent and adhesion Strengthening agent, leveling agent, neutralizing agent, dispersed for ten minutes; reconfirm the ink fineness, co...

Embodiment 3

[0028] Example 3: Main technical indicators of water-based gravure ink for film, pigment dispersion and stability: After standing for 6 months at -18°C-60°C, there is no adverse phenomenon such as pigment back-coarseness, flocculation, precipitation, gelation, etc. ;

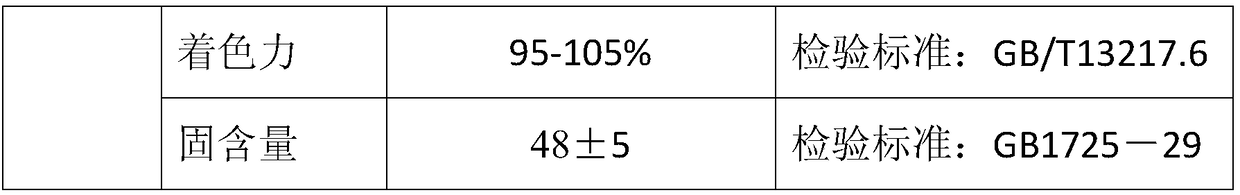

[0029] Color (scratch method): approximate standard sample;

[0030] Tinting strength (scratch method): 95-105% of the standard sample;

[0031] Fineness (scraper fineness meter method): 120°C; light resistance: ≥4 grades; adhesion fastness: ≥ 90%.

[0032] Embodiment 3: Matters needing attention in the use of water-based gravure ink for film

[0033] (1) Printing plate requirements: special printing plates for water-based inks: engraving depth: 28-32 microns.

[0034] (2) Setting of printing conditions: the printing speed is 120 m / min; the temperature of the oven is set at 50°C, and the air volume is turned on to the maximum.

[0035] (3) Solvent for ink dilution: deionized water: 95% ethanol = 3:7.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Engraving depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com