Nano-confinement zero-valent iron@spindle type porous carbon catalytic oxidation water treatment method

A nano-confinement and catalytic oxidation technology, which is applied in the field of nano-materials and water treatment, can solve the problems of easy damage to the metal frame structure and high use temperature, and achieve the effect of wide pH range, low usage, and inhibition of clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

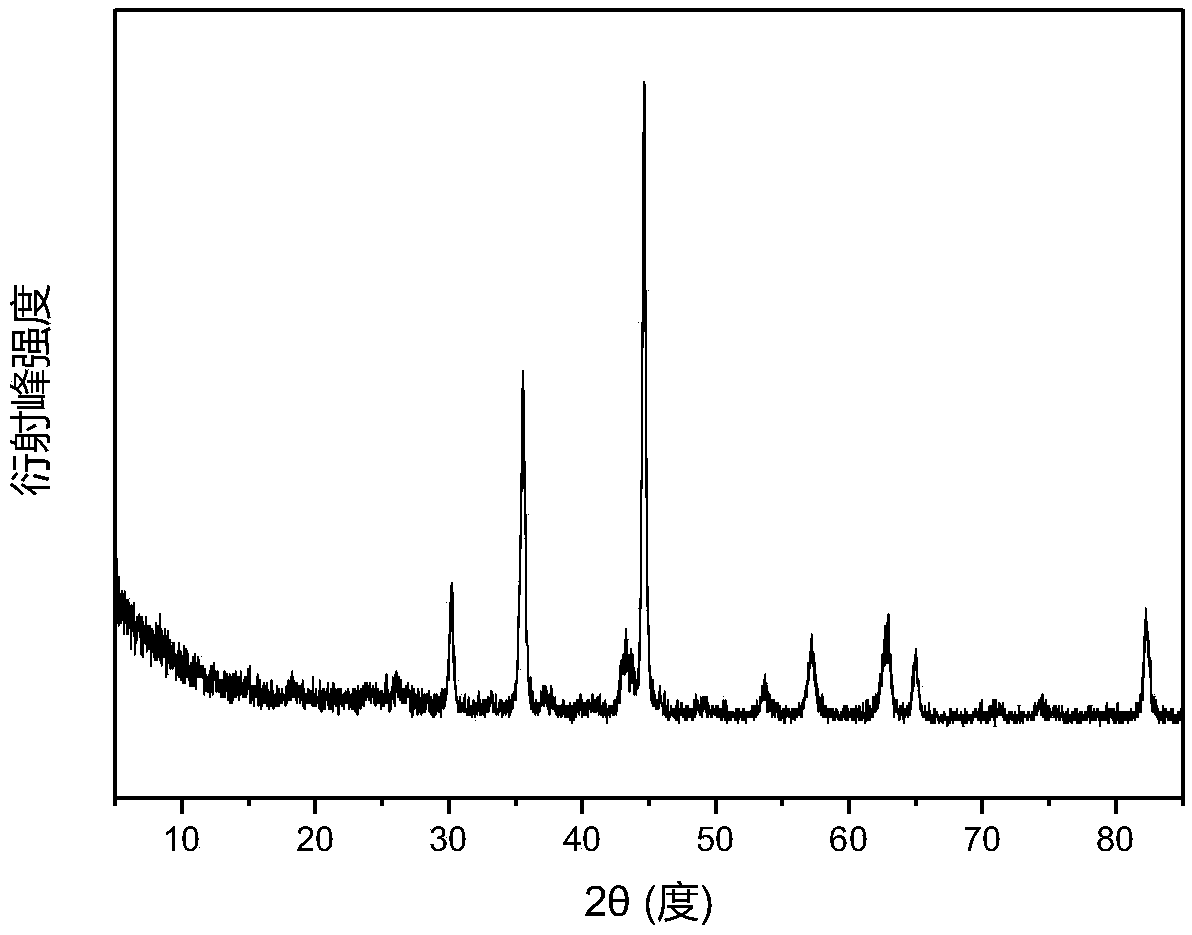

[0024] Example 1 Method for preparing nano-confined zero-valent iron@spindle-type porous carbon

[0025] Take 10g of urea in an alumina crucible with a cover, place it in a muffle furnace, raise it from room temperature to 550°C at a heating rate of 2°C / min, keep it at this temperature for 4h, and cool it down to room temperature naturally block g-C 3 N 4 , then block the g-C 3 N 4 Grind into powder; 0.674g FeCl 3 ·6H 2 O, 0.415g 2-aminoterephthalic acid, 56mL N,N-dimethylformamide were added to the beaker, and stirred at room temperature to a transparent solution; take the synthesized g-C 3 N 4 Take 280 mg and add it to the solution under stirring, ultrasonicate it for 30 minutes, then stir at room temperature for 30 minutes to obtain a suspension; transfer the suspension to a high-pressure reactor with a polytetrafluoroethylene liner, seal it with a stainless steel shell Put it in an oven at 443K for 24 hours; cool slowly to room temperature, centrifuge the mixture to...

Embodiment 2

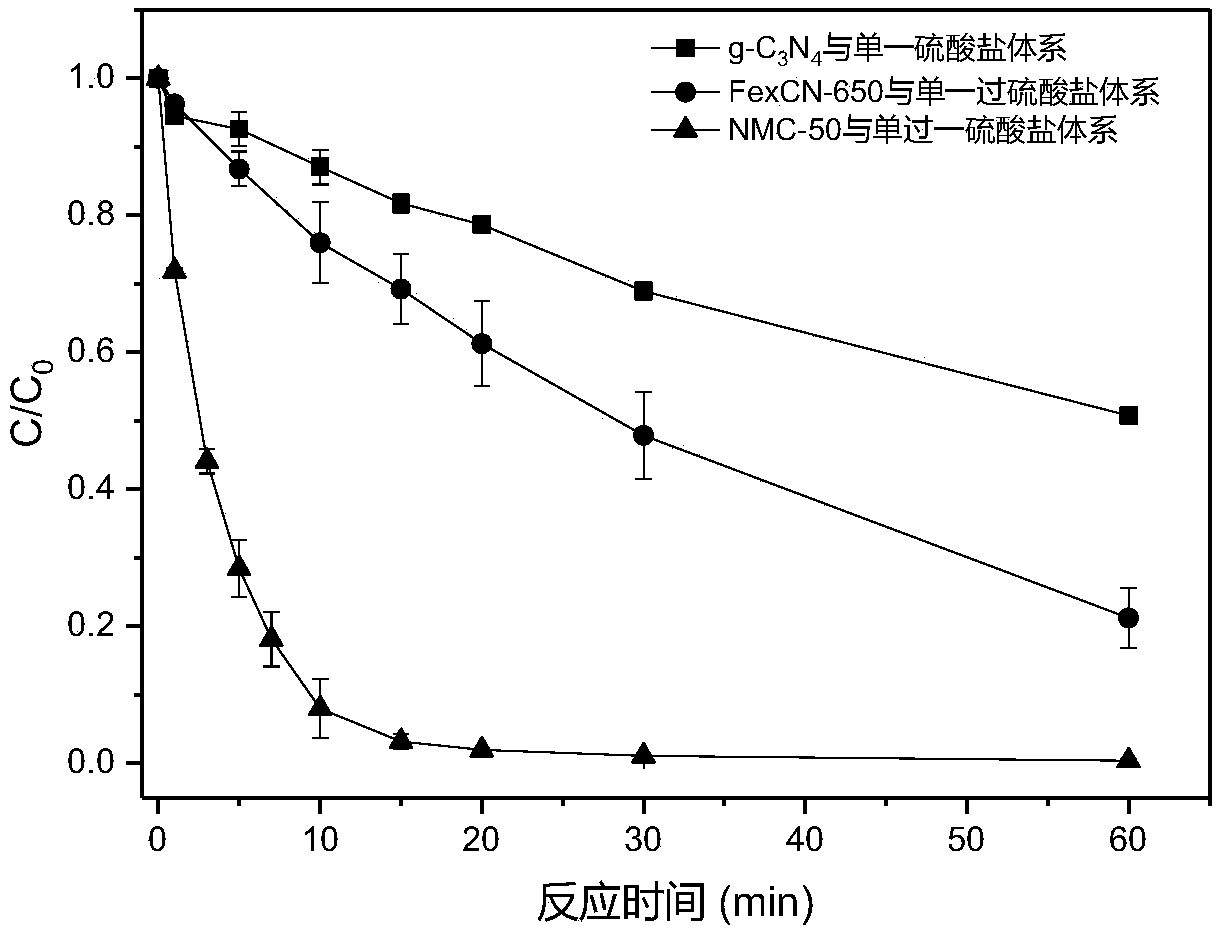

[0027]The nano-confined zero-valent iron@spindle-shaped porous carbon material prepared in Example 2 is used as a catalyst to remove organic pollutants in water

[0028] Adopt 250mL beaker as reactor, dispose 200mL reaction solution, adjust solution pH with 0.1M NaOH to be 7.0, wherein catalyst dosage is 50mg / L, potassium persulfate concentration is 0.65mM, the concentration of organic pollutant benzocaine It was 10mg / L, and the reaction was carried out with sufficient stirring at room temperature for 1h.

[0029] The nano-confined zero-valent iron@spindle-shaped porous carbon material activated persulfate in this embodiment can effectively oxidize and degrade benzocaine in water, and the benzocaine is basically completely removed after 1 hour of reaction. Depend on image 3 It can be seen that the effect of activated persulfate degrading pollutants by carbon nitride alone is not good, and the catalytic effect of activated persulfate degraded by a single metal organic framewo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com