Current collector, positive electrode plate fabricated by employing same and battery cell

A current collector and tab technology, which is applied in the field of positive pole pieces and batteries, can solve the problems of poor electrical conductivity of polymer collectors, failure to meet the needs of battery use, poor adhesion of active materials, etc., to reduce the probability of burrs and short circuits , Improve the conductivity and uniformity of conductivity, and improve the effect of adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

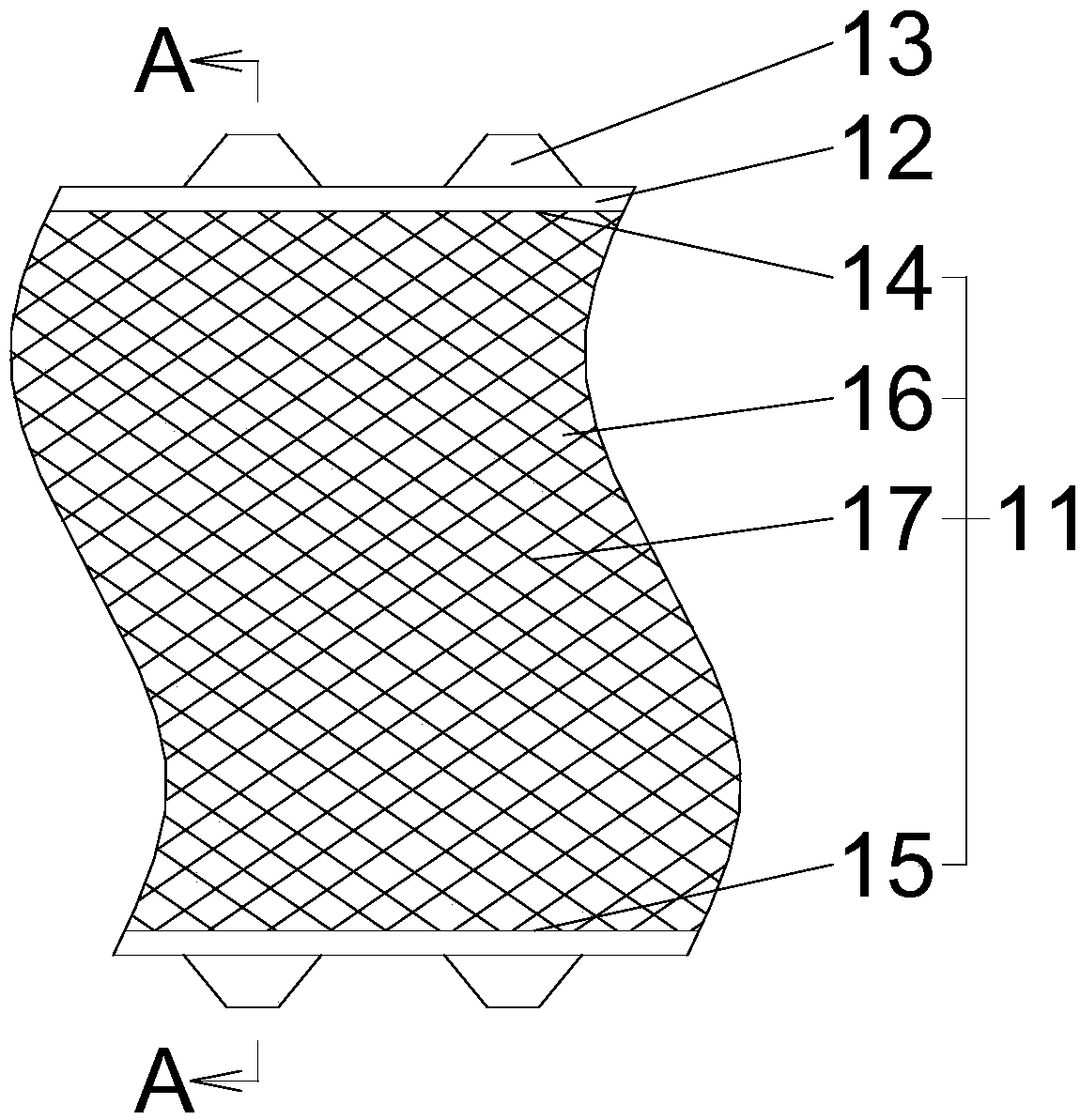

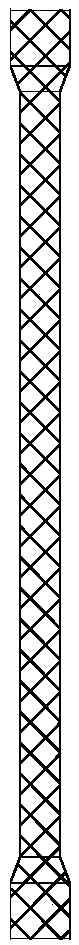

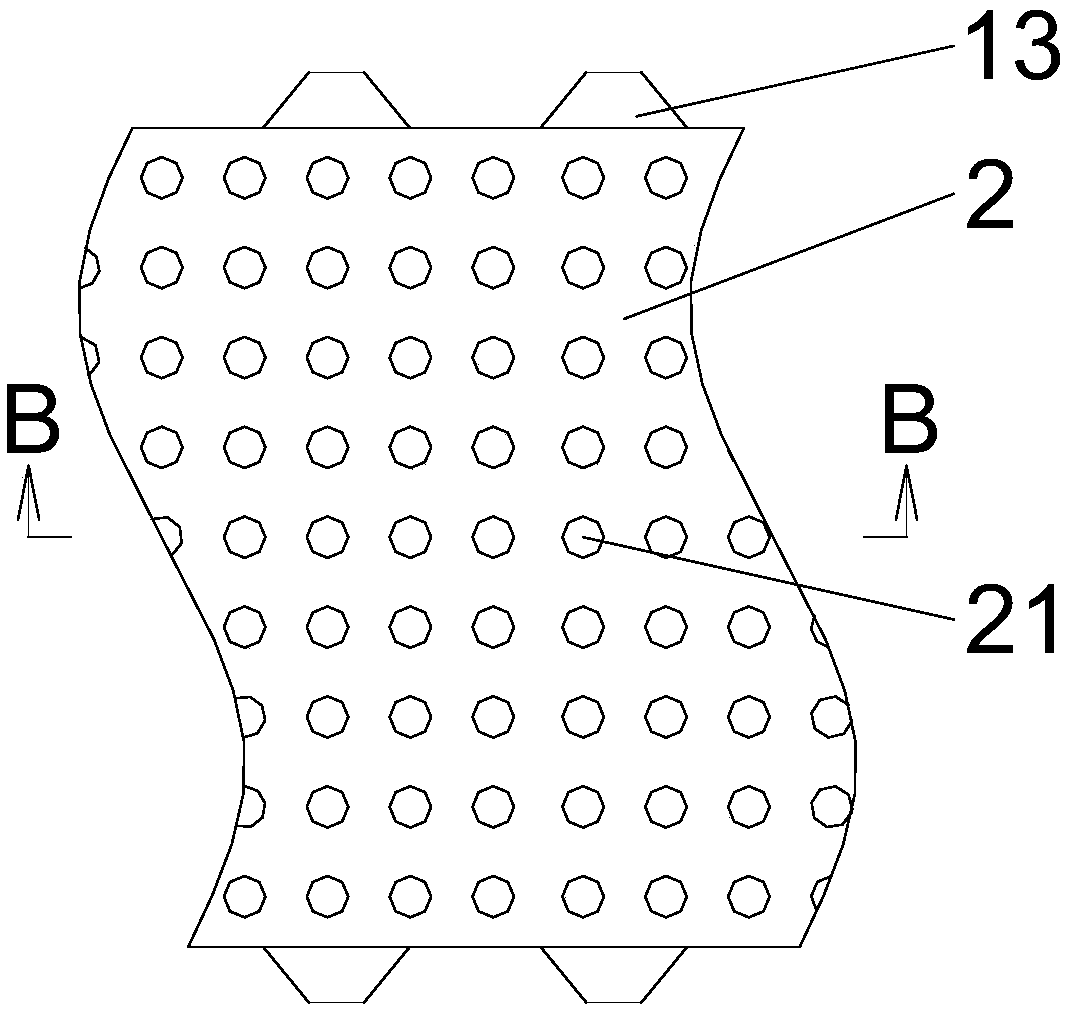

[0023] A current collector, such as attached Figure 1~4 As shown, a conductive mesh 1 and a polymer porous membrane 2 are included.

[0024] as attached figure 1 , 2 As shown, the conductive mesh 1 includes a grid area 11, a transition area 12, and a tab area 13. The transition area 12 is respectively located on a group of opposite sides 14, 15 of the grid area 11, and the transition area 12 is along the sides 14, 15, respectively. 15 continuous strips, the outer side of transition zone 12, that is, the side where transition zone 12 connects with grid zone 11, its opposite side, is connected with tab region 13, grid zone 11, transition zone 12, pole The thickness of the ear region 13 increases successively. The material of the conductive mesh 1 is one of aluminum, nickel, graphite, etc., and it is made by roll forming. The shape of the mesh 16 on the grid area 11 is rhombus, square, etc.

[0025] as attached image 3 , 4 As shown, the upper and lower surfaces of the con...

Embodiment 2

[0034] It is basically the same as Example 1, the difference is that the polymer porous membrane and the surface of the conductive network are adhered by bonding. At this time, the polymer porous membrane is a double-layer film formed by a base layer and an adhesive layer, and the material of the base layer is PET, One of PP, PE, etc., the material of the adhesive layer is one of HMA, SIS, etc., and the polymer porous film is bonded to the surface of the conductive mesh through the adhesive layer.

[0035] The holes on the polymer porous membrane on the upper and lower surfaces of the conductive mesh are opposite up and down, that is, a certain hole on the polymer porous membrane on the upper surface of the conductive mesh, the connection line on the grid area, and the polymer on the lower surface of the conductive mesh. A certain hole on the porous membrane is connected to form an electrical connection through the conductive coating. A certain hole on the polymer porous membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com