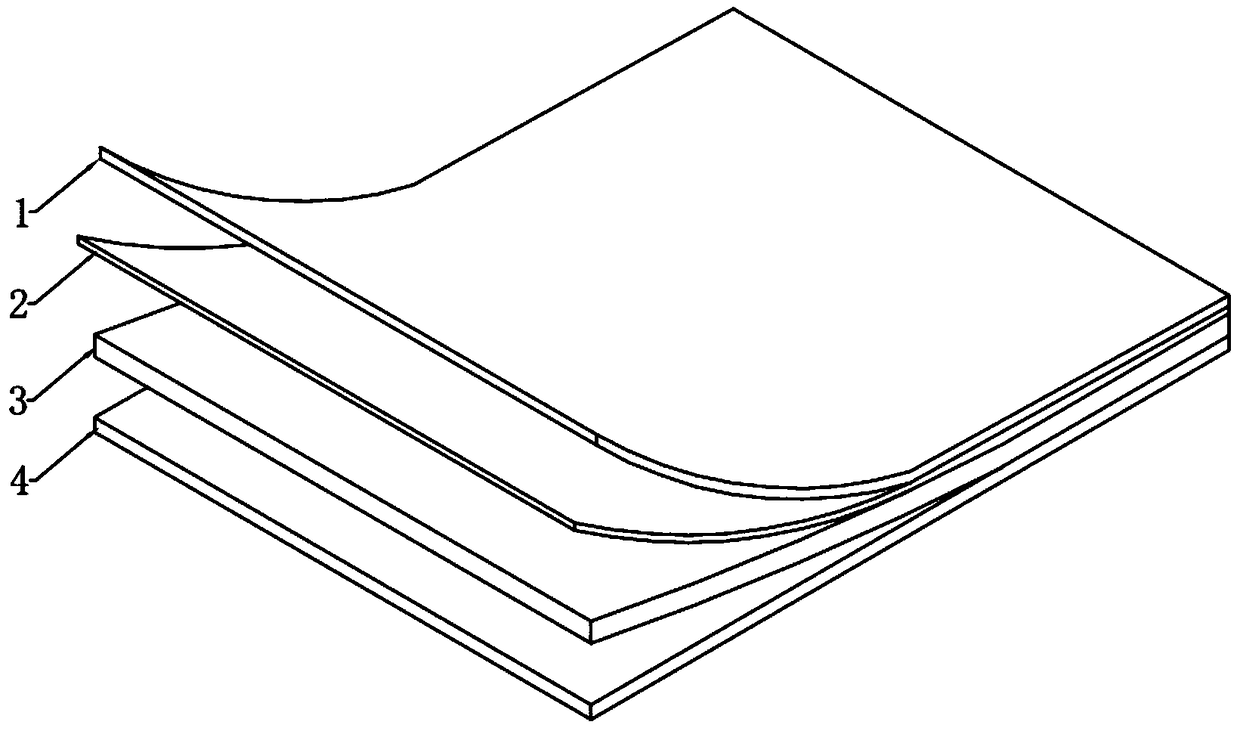

Energy-saving self-luminous laminate flooring and preparation method thereof

A composite floor and self-illuminating technology, which is applied in luminescent coatings, coatings, buildings, etc., can solve the problems of reduced afterglow performance, only consideration of luminescence, quenching when encountering water, etc., and achieves improved interface compatibility and dispersibility, low Good thermal conductivity, improve the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First take 10L of water and 90L of ethanol into the reactor, then add 1kg of KH-550 silane coupling agent, stir and hydrolyze for one hour; take 10kg of hollow glass beads (or long afterglow powder with green light) ) Add to the above system, fully stir for 4 hours, vacuum filter and wash with deionized water and absolute ethanol three times to remove excess coupling agent, dry the resulting sample under vacuum at 40°C for 6 hours and take it out for use;

[0030] (2) Mix 10kg of surface-modified hollow glass beads and 100kg of PVC resin powder, 5kg of plasticizer, 5kg of stabilizer, 5kg of foaming agent and 5kg of lubricant to obtain hollow glass beads doped and modified The base material, at the same time, put 70kg of UV curing resin, 5kg of photoinitiator, 25kg of active diluent, 1.4kg of leveling agent, and 2kg of defoamer into the high-speed shearing machine for emulsification and mixing for 40 minutes to obtain the UV curing system;

[0031] (3) Take 2kg of surface...

Embodiment 2

[0034] (1) First take 20L of water and 180L of ethanol into the reactor, and add glacial acetic acid to adjust the pH to 3.5-5.5, then add 10kg of KH-570 silane coupling agent, stir and hydrolyze for one hour; take 50kg of hollow glass Add microbeads (or long afterglow powder that emits red light) to the above system, fully stir for 2 hours, vacuum filter and wash with deionized water and absolute ethanol three times to remove excess coupling agent, and put the resulting sample at 40°C Take it out after 6 hours of vacuum drying;

[0035] (2) Mix 40kg of surface-modified hollow glass beads and 100kg of PP resin powder, 2kg of plasticizer, 2kg of stabilizer, 2kg of foaming agent and 2kg of lubricant to obtain hollow glass beads doped and modified As the base material, put 80kg of ultraviolet curing resin, 1kg of photoinitiator, 19kg of active diluent, 0.08kg of leveling agent, and 2kg of defoamer into the high-speed shearing machine to emulsify and mix for 50 minutes to obtain the ...

Embodiment 3

[0039] (1) First take 10L of water and 90L of ethanol into the reactor, then add 2kg of KB-44 titanate coupling agent, stir and hydrolyze for one hour; take 25kg of hollow glass beads (or white long afterglow Powder) was added to the above system, fully stirred for 3 hours, vacuum filtered and washed with deionized water and absolute ethanol for three times to remove excess coupling agent, the resulting sample was vacuum dried at 40°C for 6 hours and then taken out for use;

[0040] (2) Mix 20kg of surface-modified hollow glass beads and 100kg of PE resin powder, 10kg of plasticizer, 10kg of stabilizer, 5kg of foaming agent and 5kg of lubricant to obtain hollow glass beads doped and modified Base material, at the same time put 75kg of UV curing resin, 3kg of photoinitiator, 22kg of active diluent, 1kg of leveling agent and 2kg of defoamer into the high-speed shearing machine to emulsify and mix for 60 minutes to obtain the UV curing system;

[0041] (3) Take 2kg of surface-modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com