High-and-low-temperature-resistant wire harness sheathing material of new energy automobile and preparation method of high-and-low-temperature-resistant wire harness sheathing material

A new energy vehicle, high and low temperature resistant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of weak high and low temperature resistance, poor stability, easy aging of wire harness protective sleeves, etc., to achieve material The effect of excellent performance and stable material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

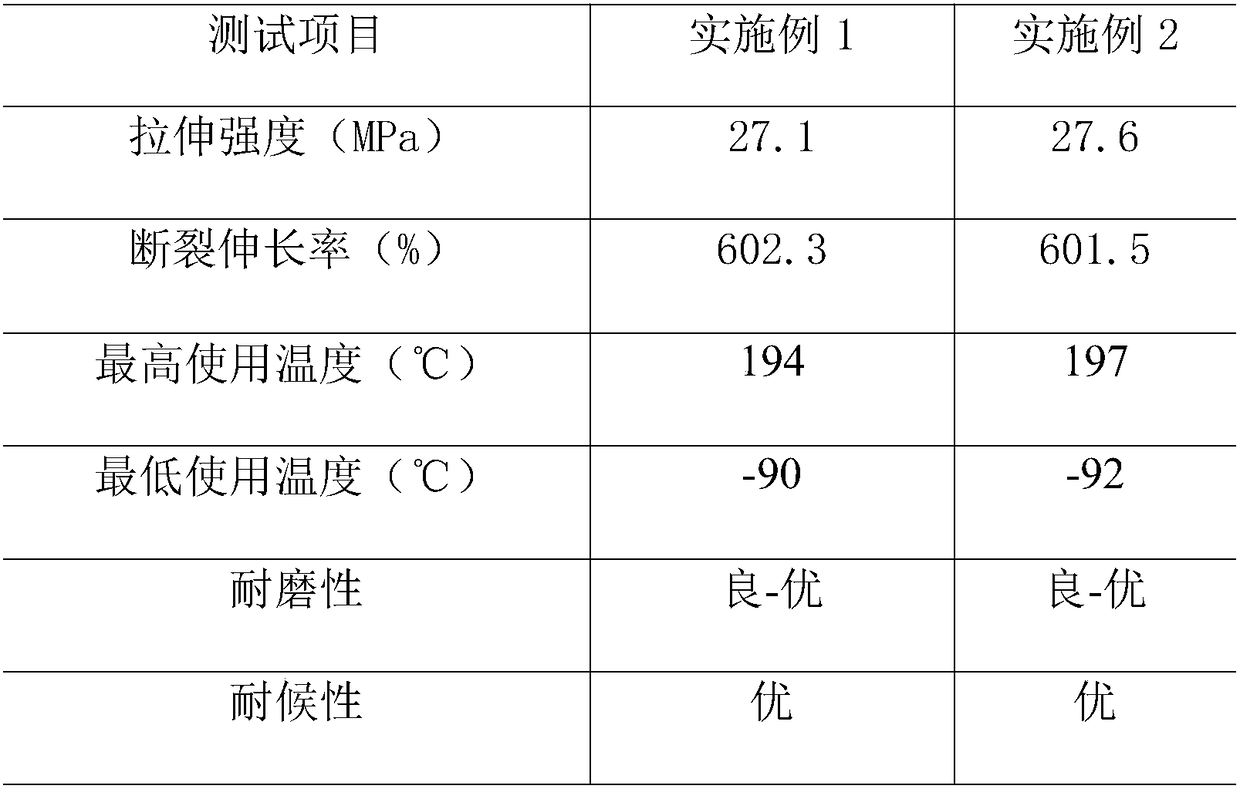

Embodiment 1

[0014] A new energy vehicle high and low temperature resistant wire harness sheath material, which is composed of the following raw materials in parts by weight: 40 parts of thermosetting liquid polyimide pure resin, 32 parts of EVA resin, 12 parts of polytetrafluoroethylene, and temperature-resistant compound modification 5 parts of agent, 8 parts of superfine activated calcium carbonate, 4 parts of diisononyl phthalate, 3 parts of lubricant, 0.7 part of antioxidant; Wherein, the preparation steps of temperature-resistant composite modifier are as follows:

[0015] In parts by weight, weigh 3 parts of sodium lignosulfonate, 4 parts of Al 2 o 3 / Mo 5 Si 3 Composite powder, 1.5 parts of expanded graphite, 7 parts of ultra-high molecular weight polyethylene and 6 parts of silane coupling agent KH-570 are placed in a grinder for 5 hours and then taken out, and then the taken out mixture is placed in a vacuum drying oven at 80°C Drying under high temperature for 10 hours to obt...

Embodiment 2

[0022] A new energy vehicle high and low temperature resistant wire harness sheath material, which is composed of the following raw materials in parts by weight: 45 parts of thermosetting liquid polyimide pure resin, 32 parts of EVA resin, 13 parts of polytetrafluoroethylene, and temperature-resistant compound modification 6 parts of agent, 8 parts of superfine activated calcium carbonate, 4 parts of diisononyl phthalate, 4 parts of lubricant, 0.9 part of antioxidant; Wherein, the preparation steps of temperature-resistant composite modifier are as follows:

[0023] In parts by weight, weigh 3 parts of sodium lignosulfonate, 4 parts of Al 2 o 3 / Mo 5 Si 3 Composite powder, 1.5 parts of expanded graphite, 7 parts of ultra-high molecular weight polyethylene and 6 parts of silane coupling agent KH-570 are placed in a grinder for 5 hours and then taken out, and then the taken out mixture is placed in a vacuum drying oven at 80°C Drying under high temperature for 10 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com