Metal/ceramic composite material and preparation method based on titanium silicon carbide ceramics and copper

A ceramic composite material, titanium silicon carbide technology, applied in the field of composite materials, can solve the problems of low thermal shock resistance of composite materials, low bonding strength of ceramic phase grains, etc., and achieve stable material properties, simple molding equipment, and stable and reliable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

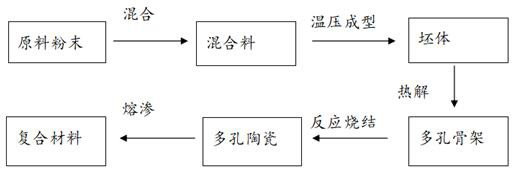

[0039] refer to figure 1 , a method for preparing a metal / ceramic composite material based on titanium silicon carbide ceramics and copper, carried out according to the following steps:

[0040](1) Preparation of ceramic green body: put 200-400M titanium silicon carbide powder and 80M sieved phenolic resin powder (mass ratio is 17:3) in a planetary ball mill at a speed of 300r / min, mix for 5h, and mix the powder Put it in a stainless steel mold coated with boron nitride release agent, carry out warm pressing molding on a flat vulcanizing machine, set the temperature of the upper and lower platens of the flat vulcanizing machine to 180°C, and the pressure to 10MPa, hold the pressure for 30min, and get a ceramic green body after demoulding .

[0041] (2) Preparation of porous ceramics: ceramic green body in N 2 Pyrolysis under atmosphere protection, carbonization of phenolic resin, atmospheric pressure (1atm), nitrogen flow rate 0.5L / min, heating to 650°C at a heating rate of ...

Embodiment 2

[0046] refer to figure 1 , a method for preparing a metal / ceramic composite material based on titanium silicon carbide ceramics and copper, carried out according to the following steps:

[0047] (1) Preparation of ceramic green body: put 200-400M titanium silicon carbide powder and 80M sieved phenolic resin powder (mass ratio is 17:3) in a planetary ball mill at a speed of 300r / min, mix for 5h, and mix the powder Put it in a stainless steel mold coated with boron nitride release agent, carry out warm pressing molding on a flat vulcanizing machine, set the temperature of the upper and lower platens of the flat vulcanizing machine to 180°C, and the pressure to 10MPa, hold the pressure for 30min, and get a ceramic green body after demoulding .

[0048] (2) Preparation of porous ceramics: ceramic green body in N 2 Pyrolysis under atmosphere protection, carbonization of phenolic resin, atmospheric pressure (1atm), nitrogen flow rate 0.5L / min, heating to 650°C at a heating rate of...

Embodiment 3

[0052] refer to figure 1 , a method for preparing a metal / ceramic composite material based on titanium silicon carbide ceramics and copper, carried out according to the following steps:

[0053] (1) Preparation of ceramic green body: put 200-400M titanium silicon carbide powder and 80M sieved phenolic resin powder (mass ratio is 17:3) in a planetary ball mill at a speed of 300r / min, mix for 5h, and mix the powder Put it in a stainless steel mold coated with boron nitride release agent, carry out warm pressing molding on a flat vulcanizing machine, set the temperature of the upper and lower platens of the flat vulcanizing machine to 180°C, and the pressure to 10MPa, hold the pressure for 30min, and get a ceramic green body after demoulding .

[0054] (2) Preparation of porous ceramics: ceramic green body in N 2 Pyrolysis under atmosphere protection, carbonization of phenolic resin, atmospheric pressure (1atm), nitrogen flow rate 0.5L / min, heating to 650°C at a heating rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com