Preparation method of carbon tube-modified molybdenum disulfide negative pole material of lithium ion battery

A technology of lithium molybdenum disulfide and ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory industrial applications, lower structural stability, and reversible capacity fading, and achieve improved structural stability and improved The effect of high conductivity and specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

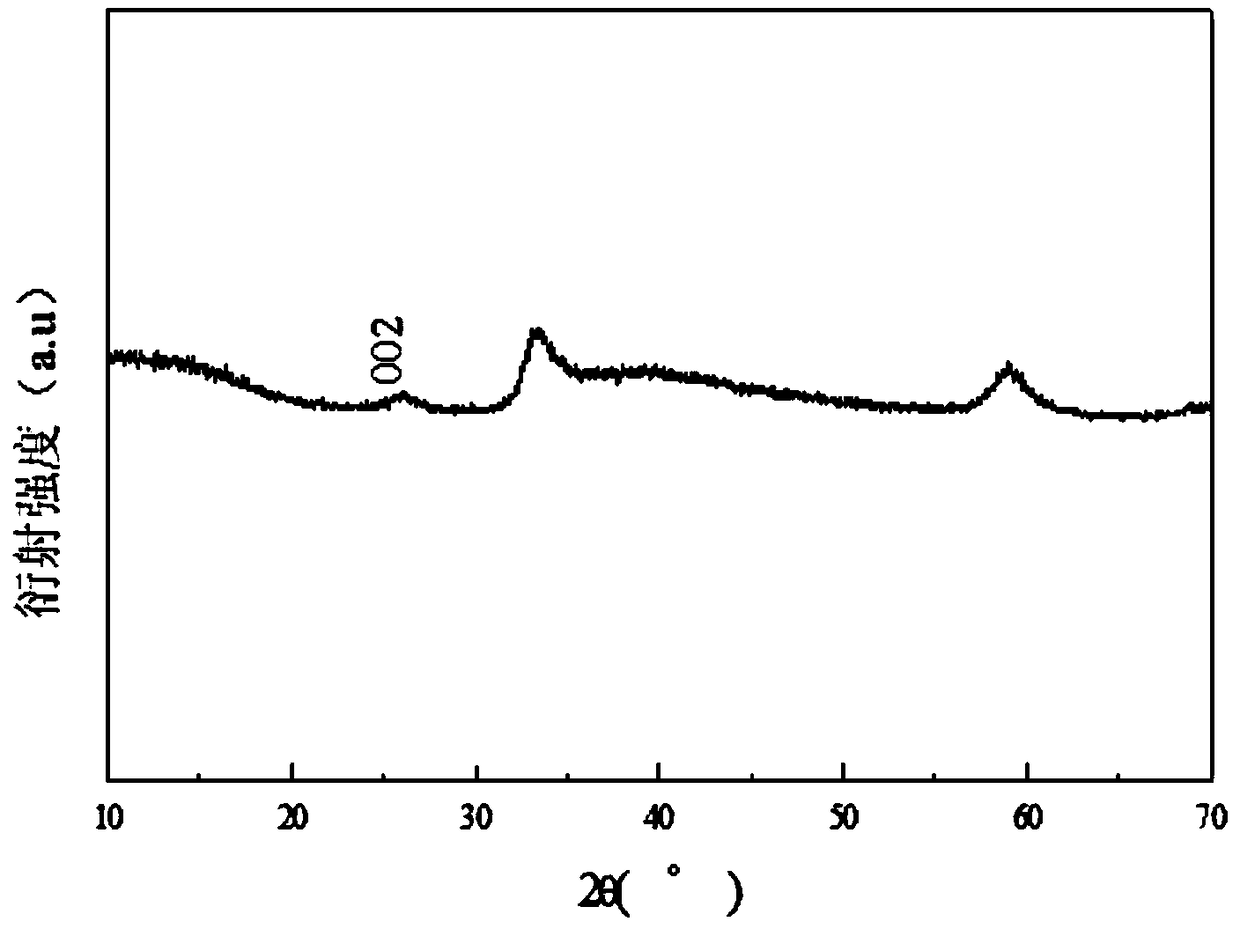

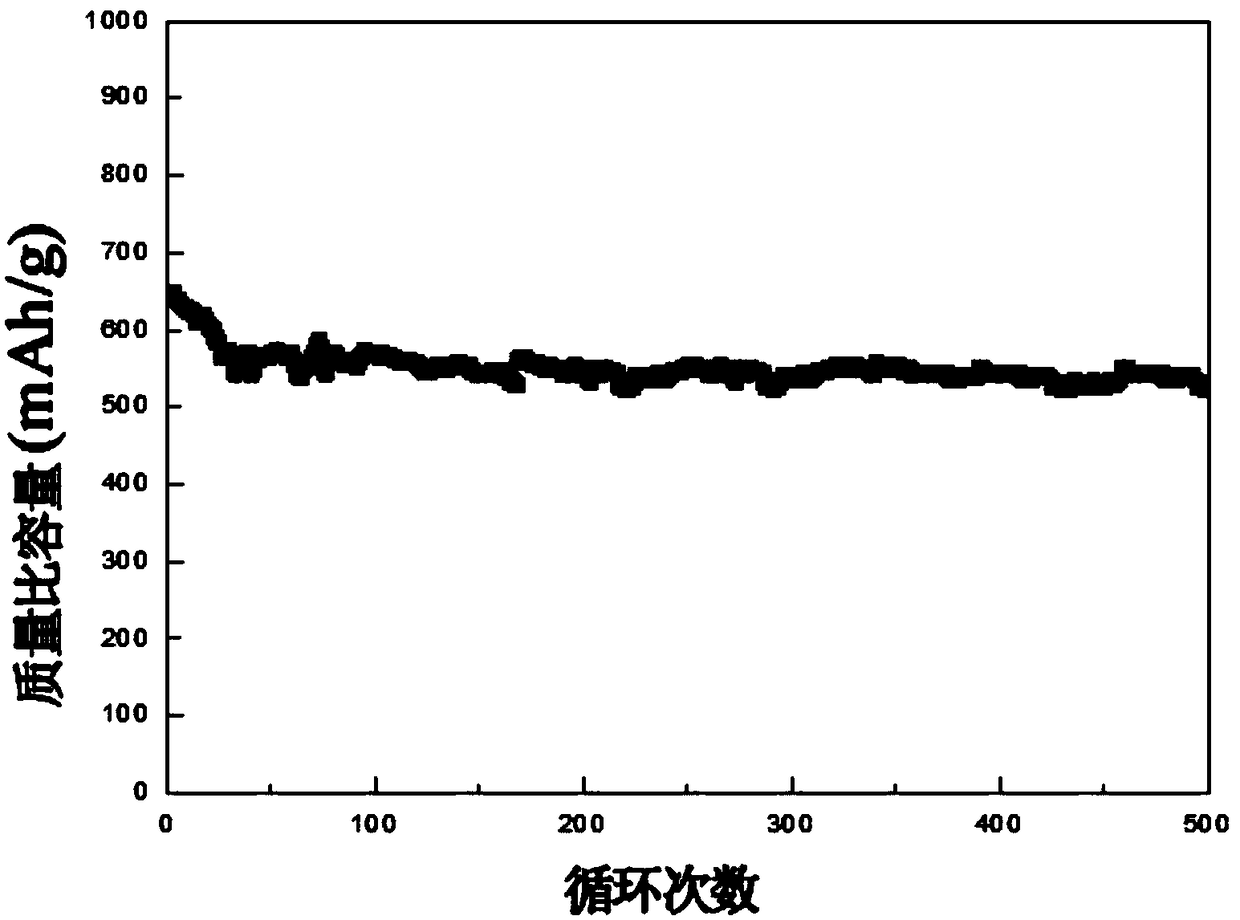

Image

Examples

Embodiment 1

[0027] 1) Preparation of precursor: according to the molar concentration ratio, L-cysteine: (NH 4 ) 2 MoO 4 =5, (NH 4 ) 2 MoO 4 : Multi-walled carbon nanotubes=1.5 Weigh corresponding materials, i.e. L-cysteine, (NH 4 ) 2 MoO 4 and multi-walled carbon nanotubes, L-cysteine, (NH 4 ) 2 MoO 4 Add the multi-walled carbon nanotubes into deionized water, stir and mix evenly, then add N-methylpyrrolidone, and add N-methylpyrrolidone and deionized water according to the volume ratio of 1.5. Gained solution is transferred to polytetrafluoroethylene hydrothermal kettle, 5 o C / min rate of heating up to 200 o C, constant temperature reaction 12h, obtain solid product, after finishing, obtain solid product with deionized water or ethanol washing, solid product is in 60 o C and dried for 6 hours to obtain the precursor.

[0028] 2) The above precursors were transferred to a quartz boat, placed in a tubular heating furnace, and circulated in a nitrogen atmosphere for 5 o C / min ...

Embodiment 2

[0031] 1) Preparation of precursor: According to the molar concentration ratio, thiourea: Na 2 MoO 4 =7, Na 2 MoO 4 : Multi-walled carbon nanotubes = 1 Weigh the corresponding materials, will be thiourea, Na 2 MoO 4 Add deionized water with multi-walled carbon nanotubes, stir and mix evenly, add N-methylpyrrolidone, add N-methylpyrrolidone and deionized water according to the volume ratio of 1, and transfer the obtained solution to polytetrafluoroethylene water hot kettle, 6 o C / min rate of heating up to 180 o C, constant temperature reaction 18h, obtain solid product, after finishing, the solid product that obtains with deionized water or ethanol washing, solid product is in 60 o C and dried for 10 hours to obtain the precursor.

[0032] 2) The above precursors were transferred to a quartz boat, placed in a tubular heating furnace, and circulated in an argon atmosphere for 10 o C / min rate of heating up to 750 o C calcination, the holding time is 4h, after the reactio...

Embodiment 3

[0035] 1) Preparation of precursor: According to the molar concentration ratio, thiourea: (NH 4 ) 2 MoO 4 =6, (NH 4 ) 2 MoO 4 : Single-walled carbon nanotubes=1.5 Weigh the corresponding materials. Thiourea, (NH 4 ) 2 MoO 4 Add deionized water with single-walled carbon nanotubes, stir and mix evenly, add N-methylpyrrolidone, add N-methylpyrrolidone and deionized water according to a volume ratio of 2, and transfer the resulting solution to polytetrafluoroethylene water hot kettle, 3 o C / min rate of heating up to 250 o C, constant temperature reaction 12h, obtain solid product, after finishing, the solid product that obtains with deionized water or ethanol washing, solid product is in 80 o C and dried for 6 hours to obtain the precursor.

[0036] 2) The above precursors were transferred to a quartz boat and placed in a tubular heating furnace, under the circulation of argon atmosphere, 3 o C / min rate of heating up to 800o C calcination, the holding time is 3h, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com