Method for preparing camellia oleifera refined oil

A technology of camellia oleifera and essential oil, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of pesticide residues in essential oils, safety and quality problems of essential oils, and achieve the effects of color clarification, oxidative stress reduction, and low aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

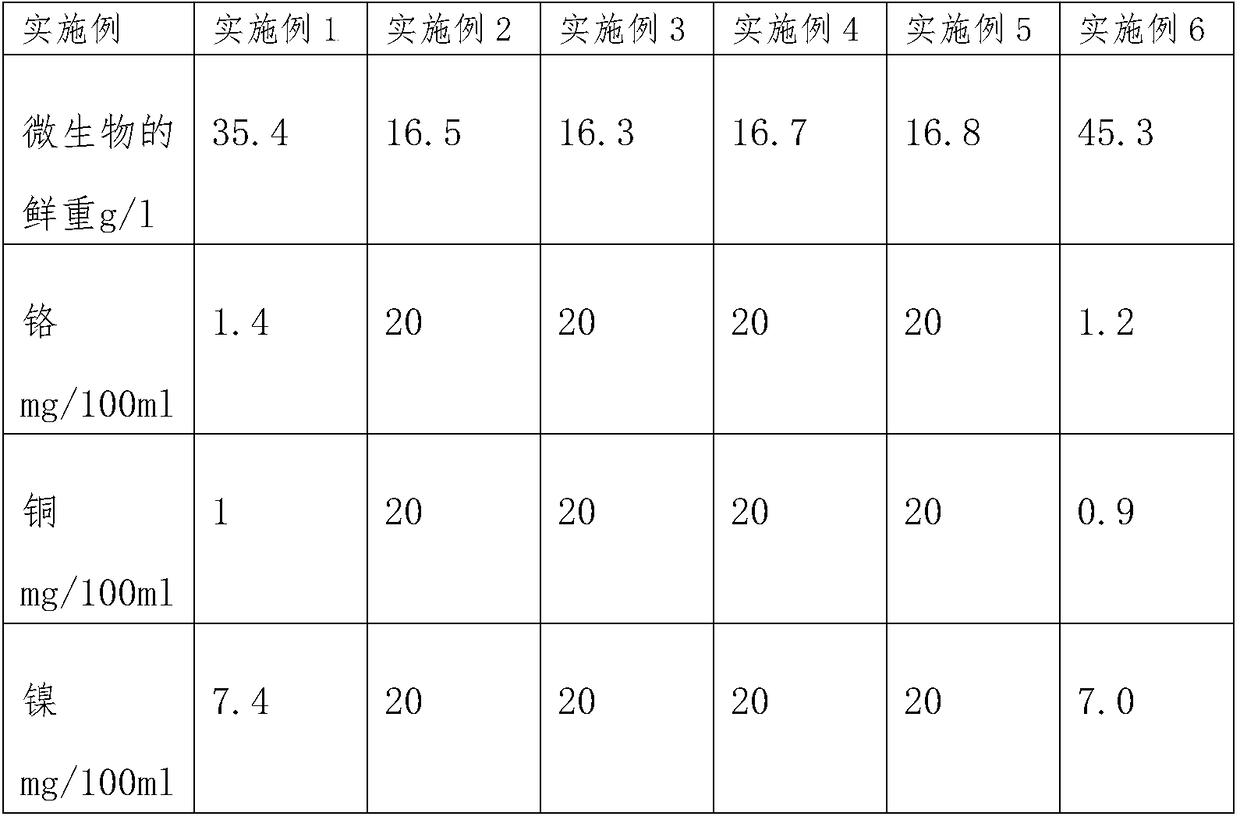

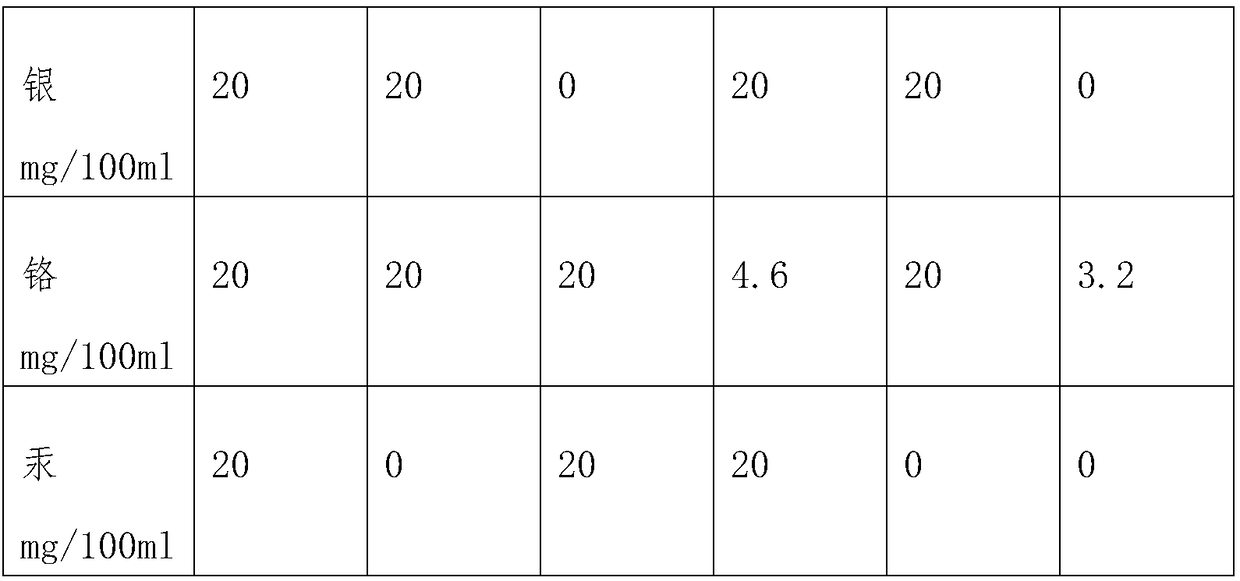

Embodiment 1

[0017] Rhizopus alicifera is added as carbon source with three kinds of pesticides of organophosphorus, organochlorine and pyrethroid pesticide, and carbon source is 0.05%, with the shake bottle loading capacity of 100ml, then add 20mg chromium, 20mg copper, 20mg nickel, 20mg of silver, 20mg of five heavy metals of chromium, 0.05% potassium hydrogen phosphate, 0.1% magnesium sulfate, 0.2% yeast extract, after culturing for 6 days at a temperature of 25°C and a pH of 6.0;

Embodiment 2

[0019] Amanita pine cones were added with organic phosphorus, organic chlorine and pyrethroid pesticides as carbon sources, and the carbon source was 0.05%. The amount was filled in a 100ml shaker bottle, and then 20mg of chromium, 20mg of copper, and 20mg of nickel were added in sequence. , 20mg of silver, 20mg of five heavy metals of chromium, 0.05% potassium hydrogen phosphate, 0.1% magnesium sulfate, 0.2% yeast extract, after culturing for 6 days at a temperature of 25°C and a pH of 6.0;

Embodiment 3

[0021] Bacillus cereus was added with organophosphorus, organochlorine and pyrethroid pesticides as the carbon source, and the carbon source was 0.05%. It was packed in a 100ml shake bottle, and then 20mg of chromium, 20mg of copper, 20mg of nickel, 20mg of silver, 20mg of five heavy metals of chromium, 0.05% potassium hydrogen phosphate, 0.1% magnesium sulfate, 0.2% yeast extract, after culturing for 6 days at a temperature of 25°C and a pH of 6.0;

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com