Process for preparing rapeseed oil by microwave method

A technology of rapeseed oil and microwave method, which is applied in the directions of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of low yield of clear oil and difficulty in extraction, etc. The effect of demulsification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

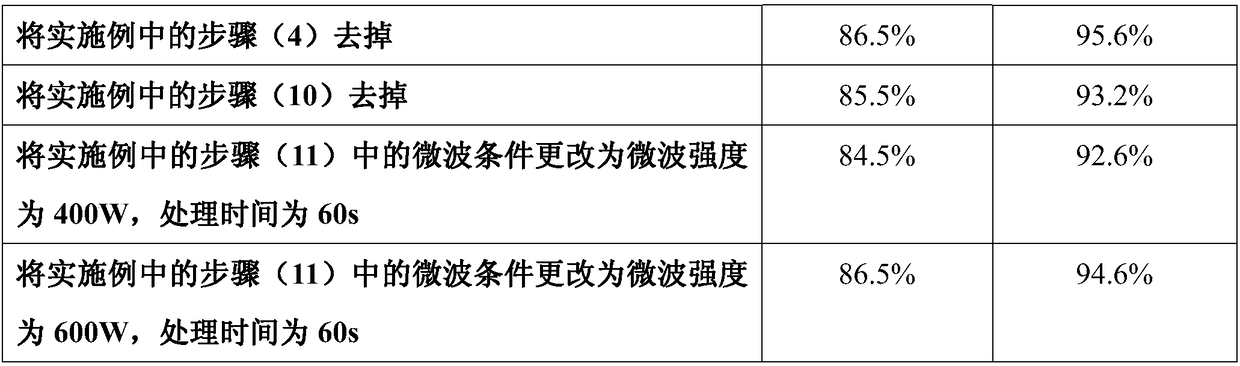

Examples

Embodiment 1

[0024] A process for preparing rapeseed oil by a microwave method, comprising the following steps: (1) seed selection: select plump rapeseeds without mildew, and use coarse and fine sieves to remove silt, dust and other sundries on the rapeseeds; (2) Crush: Dry grind the rapeseeds to 15 meshes and set aside; (3) Soak: Mix the crushed rapeseeds with water and cook them; (4) Ultrasonic: After drying the water at room temperature, mix them with water and carry out Ultrasonic treatment; (5) Enzyme addition: Add enzyme solution to the rapeseed mixture, mix well; (6) Alkaline extraction: adjust the mixture to alkaline, heat up for alkaline extraction; (7) Hydrolysis: add protease for hydrolysis ; (8) high temperature enzyme; (9) centrifugal separation, suck out the upper layer of grease; (10) add water to the lower layer of the emulsion and mix it, and then perform ultrasonic treatment again; (11) adjust the mixed solution to acidity; (12) segmental vacuum Microwave treatment: trans...

Embodiment 2

[0042] A process for preparing rapeseed oil by a microwave method, comprising the following steps: (1) seed selection: select plump rapeseeds without mildew, and use coarse and fine sieves to remove silt, dust and other sundries on the rapeseeds; (2) Crush: Dry grind the rapeseeds to 10 meshes and set aside; (3) Soak: Mix the crushed rapeseeds with water and cook them; (4) Ultrasonic: After drying the water at room temperature, mix them with water and carry out Ultrasonic treatment; (5) Enzyme addition: Add enzyme solution to the rapeseed mixture, mix well; (6) Alkaline extraction: adjust the mixture to alkaline, heat up for alkaline extraction; (7) Hydrolysis: add protease for hydrolysis ; (8) high temperature enzyme; (9) centrifugal separation, suck out the upper layer of grease; (10) add water to the lower layer of the emulsion and mix it, and then perform ultrasonic treatment again; (11) adjust the mixed solution to acidity; (12) segmental vacuum Microwave treatment: trans...

Embodiment 3

[0059] A process for preparing rapeseed oil by a microwave method, comprising the following steps: (1) seed selection: select plump rapeseeds without mildew, and use coarse and fine sieves to remove silt, dust and other sundries on the rapeseeds; (2) Crush: Dry grind the rapeseed to 20 meshes, and set aside; (3) Soak: Mix the crushed rapeseed with water, and cook; (4) Ultrasonic: After drying the water at room temperature, mix it with water, and carry out Ultrasonic treatment; (5) Enzyme addition: Add enzyme solution to the rapeseed mixture, mix well; (6) Alkaline extraction: adjust the mixture to alkaline, heat up for alkaline extraction; (7) Hydrolysis: add protease for hydrolysis ; (8) high temperature enzyme; (9) centrifugal separation, suck out the upper layer of grease; (10) add water to the lower layer of the emulsion and mix it, and then perform ultrasonic treatment again; (11) adjust the mixed solution to acidity; (12) segmental vacuum Microwave treatment: transfer th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com