Pretreatment method of walnut kernels

A walnut kernel and pretreatment technology, applied in the field of food processing, can solve problems such as high cost, protein denaturation, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

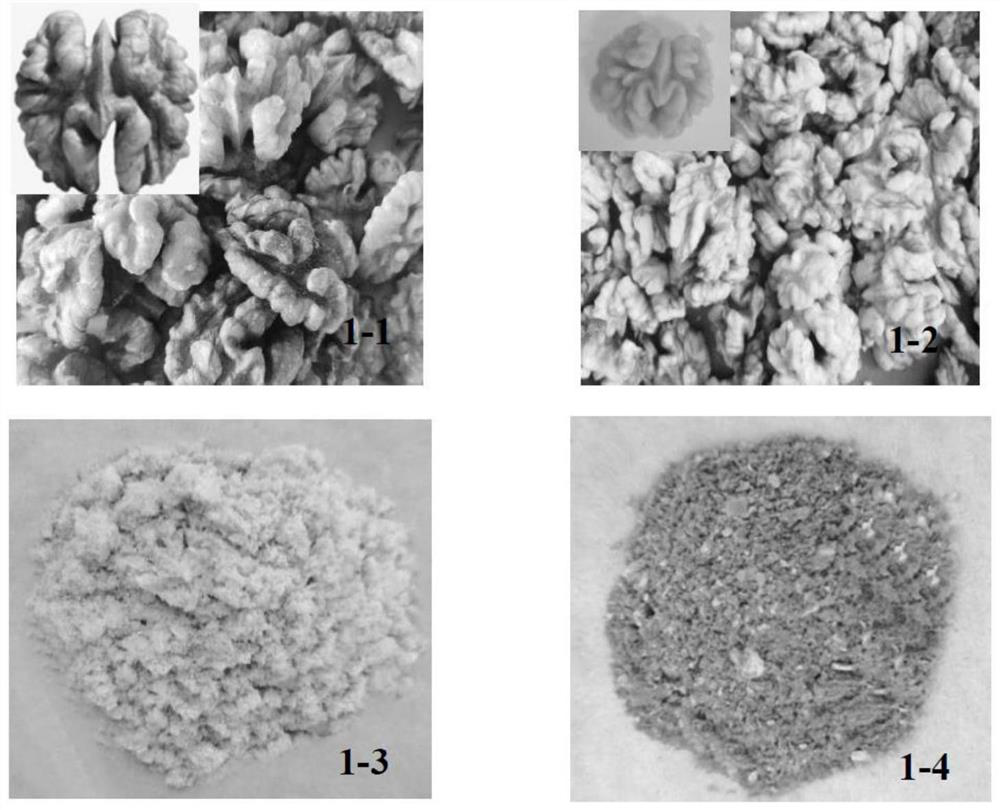

[0056] Embodiment 1: A kind of method of walnut kernel dephenolization

[0057] Prepare 70% ethanol solution, adjust the solution hydrochloric acid concentration to be 0.05mol / L, weigh 100g of commercially available Yunnan walnut kernels and complete walnut kernels, according to the ratio of the quality of walnut kernels in g to the volume of ethanol aqueous solution in mL of 1:20 Proportional mixing, put the mixed system in an ultrasonic cleaning machine, fix the ultrasonic temperature at 60°C, and the power at 200w, first use 40kHz ultrasonic treatment for 30 minutes, then 28kHz ultrasonic treatment for 30 minutes, then filter, recover dephenolized walnut kernels and dry them in an oven at 60°C Finally, moisture is removed (moisture content is less than 3%) to obtain dephenolized walnut kernels with a dephenolization rate of 97.5%.

Embodiment 2

[0058] Embodiment 2: a kind of method of walnut kernel dephenolization

[0059] Prepare 70% ethanol solution, adjust the solution hydrochloric acid concentration to be 0.05mol / L, take by weighing 200g of complete walnut kernels from Yunnan walnut kernels commercially available, according to the quality of walnut kernels in g and the volume ratio of ethanol aqueous solution in mL 1:20 Proportionally mixed, the mixed system is placed in an ultrasonic cleaning machine, the ultrasonic temperature is fixed at 60°C, and the power is 200w. First, 28kHz ultrasonic treatment is used for 30 minutes, and then 40kHz ultrasonic treatment is used for 30 minutes, and then filtered, and the dephenolized walnut kernels are recovered and dried in an oven at 60°C. Finally, the water is removed (moisture content is less than 3%), and the dephenolized walnut kernel with a dephenolization rate of more than 97.5% is obtained.

Embodiment 3

[0060] Embodiment 3: a kind of method of walnut kernel dephenolization

[0061] Prepare 70% ethanol solution, adjust the solution hydrochloric acid concentration to be 0.05mol / L, take 500g of commercially available Yunnan walnut kernels and complete walnut kernels, according to the quality of walnut kernels in g and the volume ratio of ethanol aqueous solution in mL 1:20 Proportionally mixed, put the mixed system in an ultrasonic cleaning machine, fix the ultrasonic temperature at 60°C, and the power at 190w, use 40kHz ultrasonic treatment for 30 minutes and then 28kHz ultrasonic treatment for 30 minutes, then filter, recover the dephenolized walnut kernels and dry them in an oven at 60°C Water is removed (moisture content is less than 3%) to obtain dephenolized walnut kernels with a dephenolization rate of more than 97.5%.

PUM

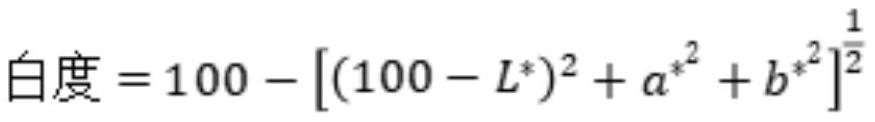

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com