3D printing device and printing method based on electrostatic spinning principle

A 3D printing and electrospinning technology, applied in the field of 3D printing, can solve the problem of not having 3D printing technology combined with electrospinning technology, etc., to achieve the effect of delicate appearance, high bonding force, and widening the range of choices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

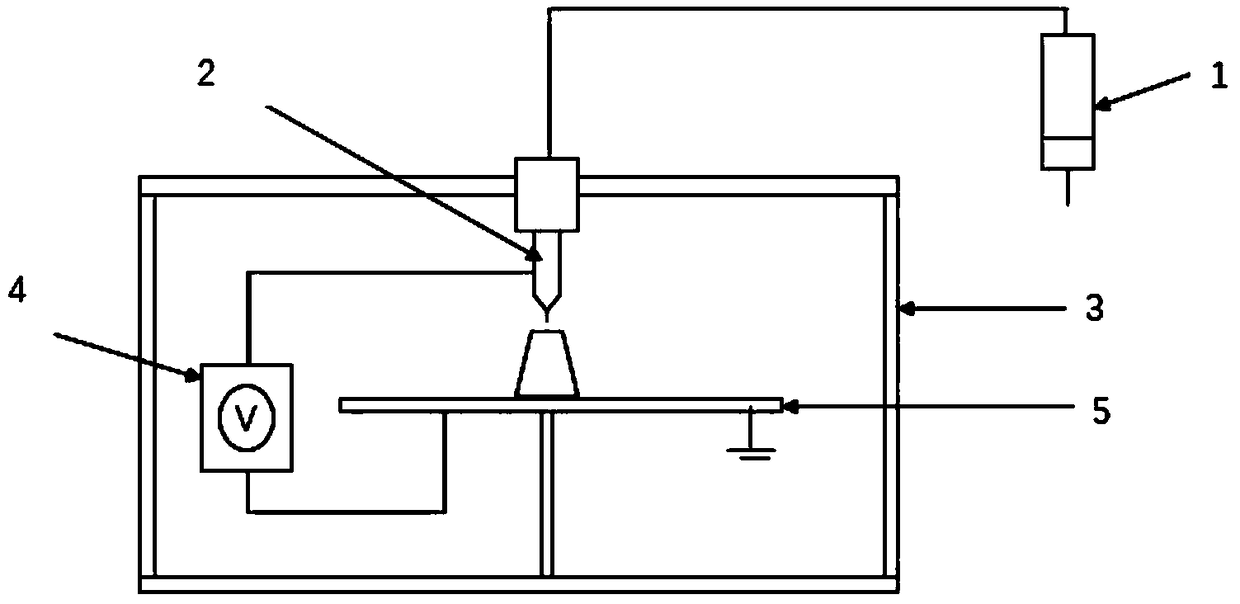

[0050] A 3D printing device based on the principle of electrospinning, the basic structure of which includes a micro-injection pump 1 . The injection outlet of the micro injection pump 1 is connected to the material receiving port of the print head 2 . The printing nozzle 2 is fixed on the three-dimensional space moving frame 3 . It also includes a receiving platform 5 located under the print head 2 . A high voltage power supply 4 is also included. The anode of the high-voltage power supply 4 is connected to the print head 2 . The negative pole of the high voltage power supply 4 is connected on the receiving platform 5 . The plane of the receiving platform 5 is divided into a plurality of grid units 10 . A voltage control device is installed below the receiving platform 5 to control the voltage of each grid unit 10 .

[0051] Receiving the voltage control device under Ping An 5, specifically the integrated circuit laid on the back of the receiving platform 5, divides the ...

Embodiment 2

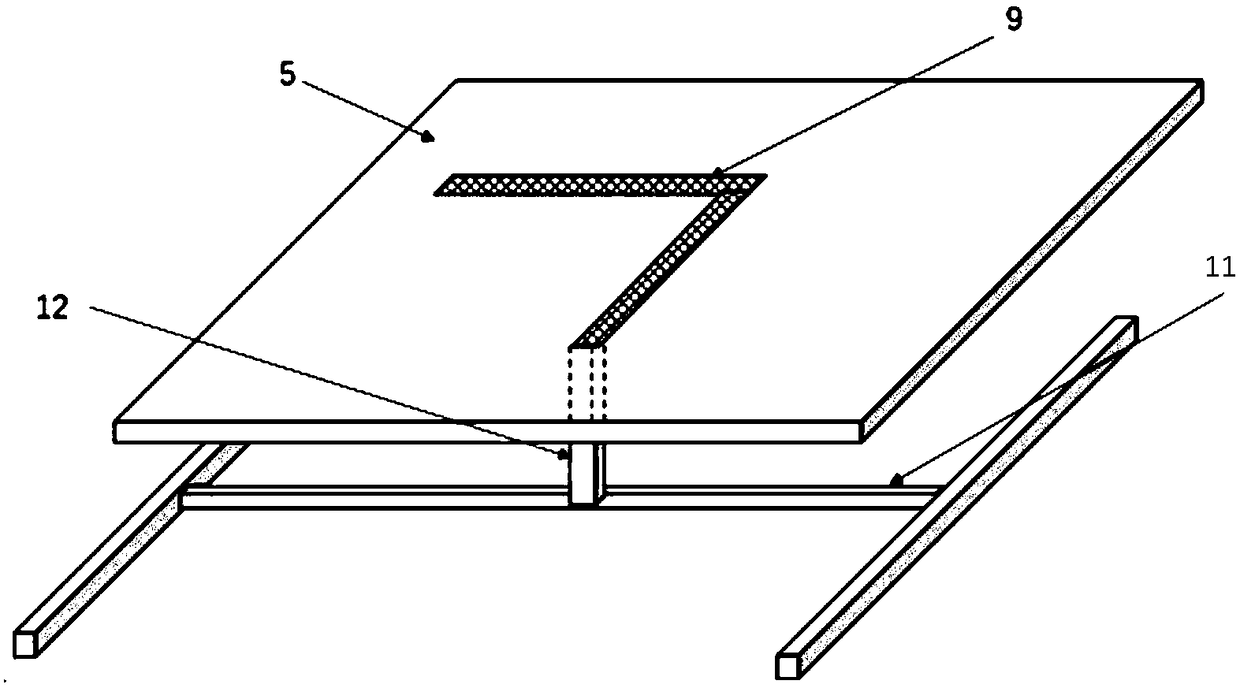

[0053] The basic structure of embodiment 2 is the same as that of embodiment 1, but the voltage control device below the receiving platform 5 is different, specifically, including the terminal control frame 11 installed below the receiving platform 5; There is a voltage control terminal 12; the terminal control frame 11 controls the voltage control terminal 12 to move in a plane parallel to the receiving platform 5; The voltage range of the voltage control terminal 12 is 0-15kv, and the receiving platform 5 is made of conductive metal. The moving path and moving speed of the voltage controlling terminal 12 are completely synchronized with the moving path and moving speed of the printing nozzle 2 .

Embodiment 3

[0055] The basic structure of embodiment 3 is the same as embodiment 1.

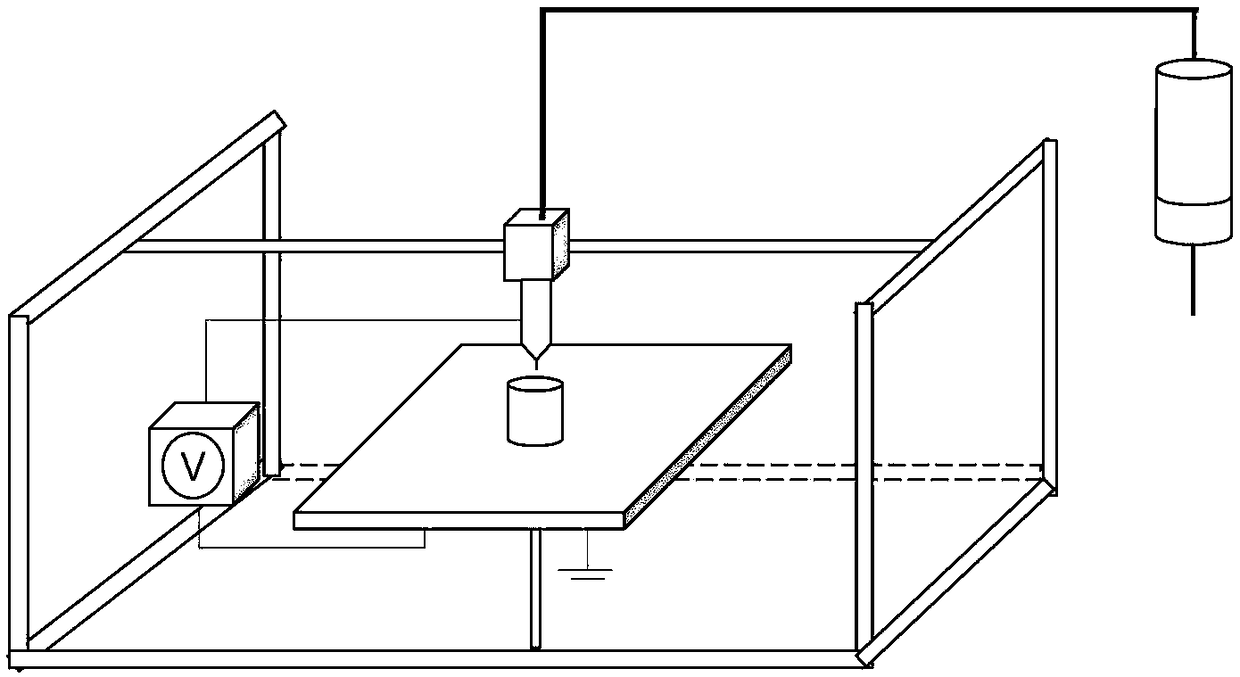

[0056] Specifically, a high polymer for printing dissolved in a volatile solvent is placed in the micro-injection pump 1, and the printing material is extruded through the micro-injection pump 1 at a room temperature of 20°C and a relative humidity of 25%. 1 is connected with the printing nozzle 2 by a hose, and the polymer forms a fine jet at the tip of the printing nozzle 2 under the action of the high-voltage electrostatic field generated by the high-voltage power supply 4, and the three-dimensional space moving frame 3, that is, the three-dimensional gantry frame controls the printing nozzle 2 Mobile printing, at the same time, the micro-cooling and hot air control device 8 outputs hot air to accelerate the volatilization of the solvent, so that the material is solidified. After the cross-section of one layer is printed, the receiving platform 5 is lowered to the height of one layer and printed again....

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com