Preparation device and preparation method of modified biomass charcoal for soil treatment

A biochar and preparation device technology, applied in the field of soil treatment, can solve the problems of long time consumption, low adsorption stability efficiency, unsatisfactory effect, etc., and achieve the effect of strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

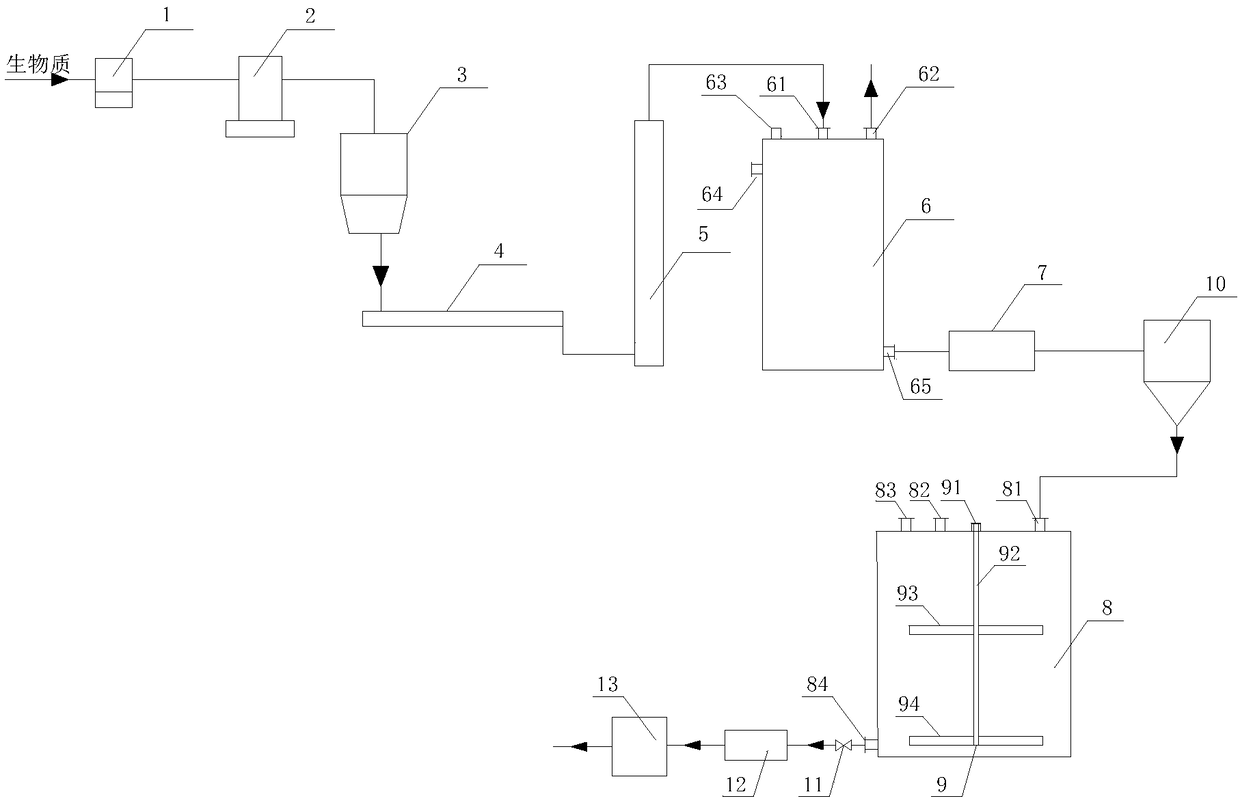

[0027] Such as figure 1 As shown, a preparation device for modified biochar for soil treatment, including a pulverizer 1, a granulator 2, a biomass bin 3, a conveyor 4, a hoist 5, a carbonization furnace 6, a cooler 7, Modification reactor 8, agitator 9, biochar storage tank 10, filter 12 and dryer 13; the top of carbonization furnace 6 is provided with biomass inlet 61, carbonization gas outlet 62 and temperature measuring hole 63, carbonization furnace 6 The upper part of the side wall is provided with a flue gas outlet 64, and the lower part of the side wall of the carbonization furnace 6 is provided with a biomass charcoal outlet 65; the top of the modification reactor 8 is provided with a biomass charcoal feeding port 81, a modifier feeding port 82 and a temperature measuring device. Port 83, modifying agent feeding port 82 is used to add modifying agent, the bottom of modifying reactor 8 side walls is provided with discharge port 84, is provided with agitator 9 in modify...

Embodiment 2

[0037] A preparation device for modified biochar for soil treatment, the same as in Example 1.

[0038] A preparation method for modified biochar for soil treatment, comprising the following steps:

[0039] (a) Raw material preparation: the agricultural and forestry wastes are cleaned with tap water and dried naturally, and the agricultural and forestry wastes are straws;

[0040](b) Pulverization: the agricultural and forestry wastes are then sent to the pulverizer 1 through the biomass conveying pipeline for pulverization, and the pulverized agricultural and forestry wastes have a particle size of 10-50 mesh;

[0041] (c) granulation: sending the agricultural and forestry waste pulverized in step (b) into the granulator 2 for granulation to obtain granules, and sending the granules through the conveyor 4 and into the hoist 5;

[0042] (d) Preparation of biochar: send the particles described in step (c) into the carbonization furnace 6 through the top of the hoist 5 and calc...

Embodiment 3

[0046] A preparation device for modified biochar for soil treatment, the same as in Example 1.

[0047] A preparation method for modified biochar for soil treatment, comprising the following steps:

[0048] (a) Raw material preparation: the agricultural and forestry wastes are cleaned with tap water and dried naturally, and the agricultural and forestry wastes are straws;

[0049] (b) Pulverization: the agricultural and forestry wastes are then sent to the pulverizer 1 through the biomass conveying pipeline for pulverization, and the pulverized agricultural and forestry wastes have a particle size of 10-50 mesh;

[0050] (c) granulation: sending the agricultural and forestry waste pulverized in step (b) into the granulator 2 for granulation to obtain granules, and sending the granules through the conveyor 4 and into the hoist 5;

[0051] (d) Preparation of biochar: send the particles described in step (c) into the carbonization furnace 6 through the top of the hoist 5 and cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com